Reinforcement covering layer thickness positioner and use method as well as application thereof

A technology of steel protective layer and locator, which is applied in the directions of buildings, building reinforcements, building components, etc., can solve the problems of heavy workload, difficult to stick into steel bars, lack of elasticity, etc., and achieves good stiffness and strength performance, and is not easy to fall off and move. The effect of position and assembly is convenient and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

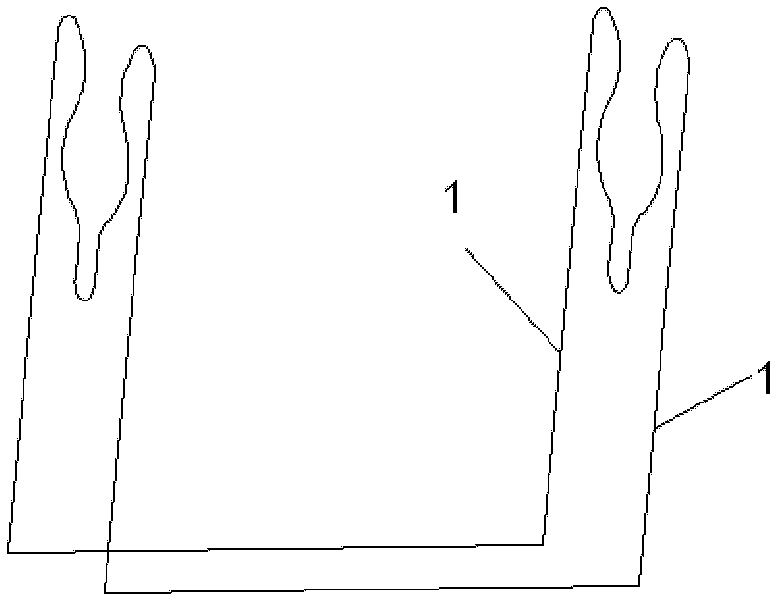

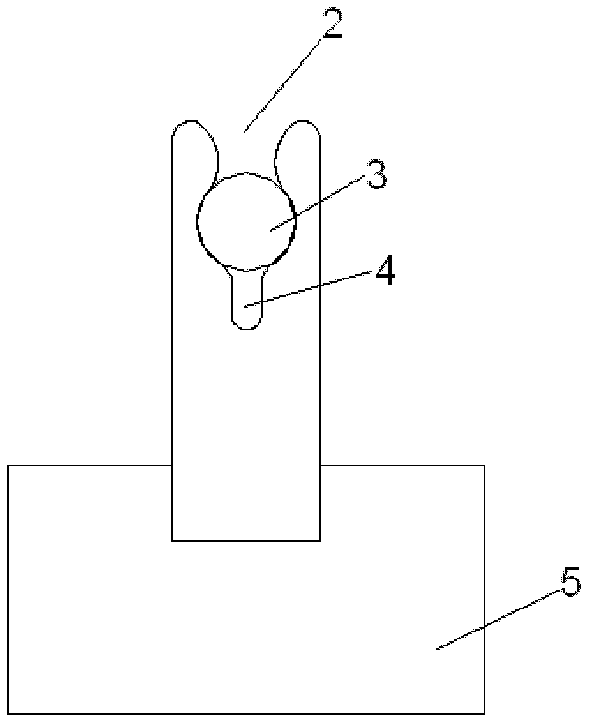

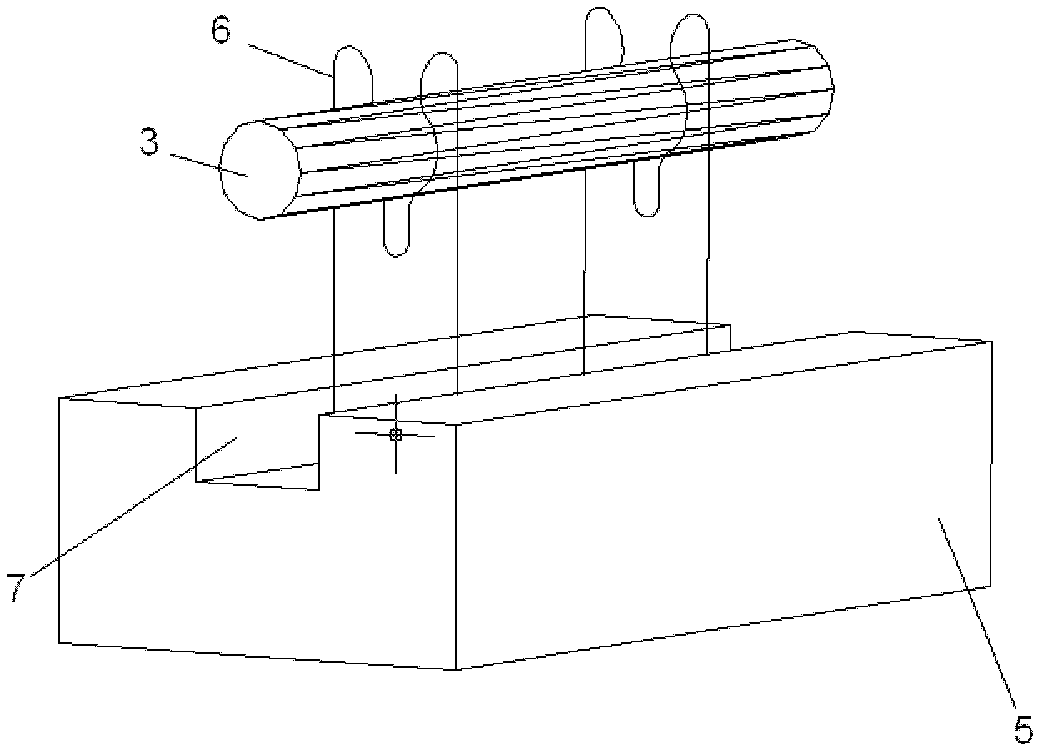

[0047] Such as Figure 1 to Figure 3 As shown, the thickness locator of the steel bar cover includes a clamping mechanism 6 formed by bending a steel wire; the clamping mechanism 6 is composed of a clamping mouth 8, a clamping throat 10, a clamping cavity 11 and an elastic cavity 9; the elastic cavity 9 is not The size before being clamped into the steel bar 3 is smaller than the diameter of the steel bar 3, and the size after being clamped into the steel bar 3 is the same as the diameter of the steel bar 3; the elastic cavity 9 includes an outer elastic cavity 2 and an inner elastic cavity 4; the clamping mechanism 6 The number is two sets, and each set of clamping mechanism 6 is provided with two independent legs 1; the legs 1 of the clamping mechanism are connected and fixed with the mortar block 5; the distance between the legs 1 is greater than that of the mortar pad The width of the card slot 7 provided on the block 5, and the support foot 1 and the mortar pad 5 are sque...

Embodiment 2

[0049] Such as Figure 4 to Figure 6 As shown, the thickness locator of the steel bar cover includes a clamping mechanism 6 formed by bending a steel wire; the clamping mechanism 6 is composed of a clamping nozzle 8, a clamping throat 10, a clamping cavity 11 and an elastic cavity 9; the elastic cavity 9 The size before being clamped into the reinforcing bar 3 is smaller than the diameter of the reinforcing bar 3, and the size after being clamped into the reinforcing bar 3 is the same as the diameter of the reinforcing bar 3; the number of the clamping mechanism 6 is one set, and each set of clamping mechanism 6 is provided with Two independent legs 1; the legs 1 of the clamping mechanism 6 are connected and fixed to the mortar block 5; the legs 1 form an integrated embedded connection and fixing structure with the mortar block 5 by being directly embedded during manufacture ; The clamping mechanism 6 is a structure formed by bending high-strength carbon steel wire. This stru...

Embodiment 3

[0051] Such as Figure 7 and Figure 8 As shown, the thickness locator of the steel bar cover includes a clamping mechanism 6 formed by bending a steel wire; the clamping mechanism 6 is composed of a clamping nozzle 8, a clamping throat 10, a clamping cavity 11 and an elastic cavity 9; the elastic cavity 9 The size before being clamped into the reinforcing bar 3 is smaller than the diameter of the reinforcing bar 3, and the size after being clamped into the reinforcing bar 3 is the same as the diameter of the reinforcing bar 3; the number of the clamping mechanism 6 is one set, and each set of clamping mechanism 6 is provided with Two independent legs 1; the legs 1 of the clamping mechanism 6 are connected and fixed to the mortar block 5; the legs 1 are inserted into the reserved holes provided on the mortar block 5 to form a plug-in connection and fixing structure; The diameter of the reserved hole matches the diameter of the foot 1; the clamping mechanism 6 is a structure f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com