Thermal deformation tester for cement-emulsified asphalt mortar material

A thermal deformation tester, cement emulsified asphalt technology, applied in the direction of material thermal analysis, analysis materials, instruments, etc., can solve the problem that the thermal deformation performance of cement emulsified asphalt mortar is not suitable for testing, so as to reduce the accuracy requirements, ensure accuracy, The effect of guaranteeing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment this patent is further described.

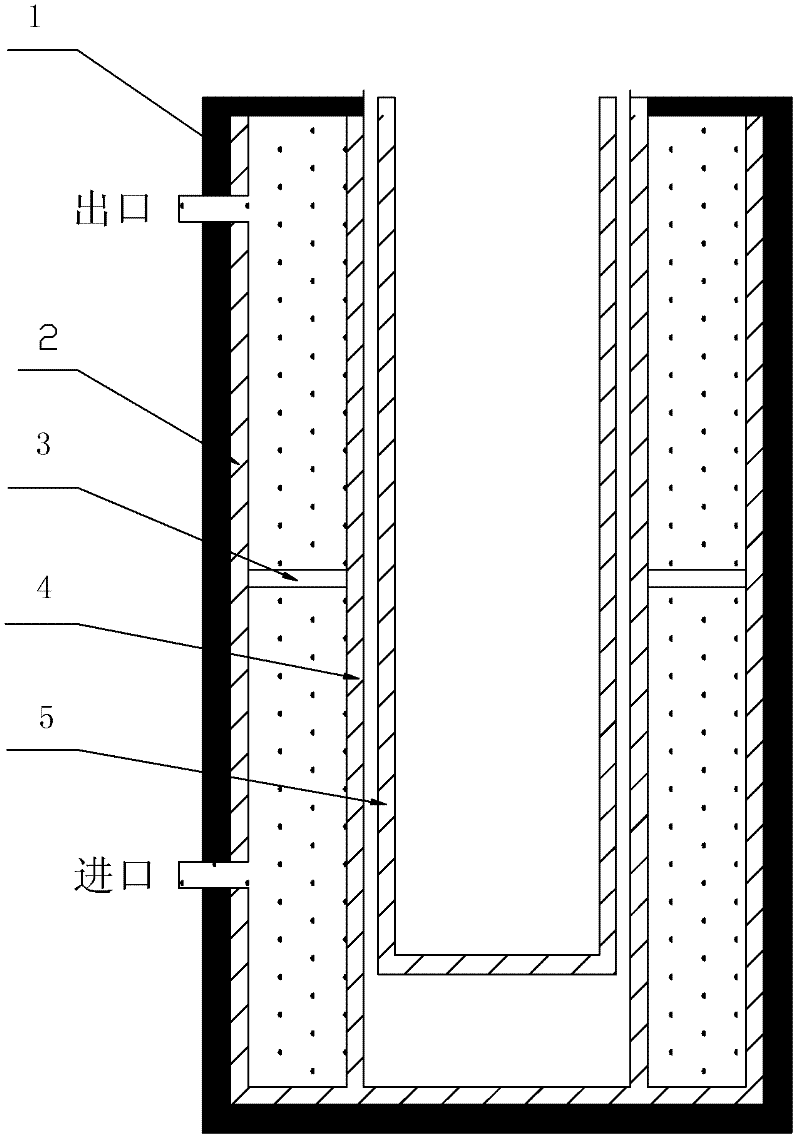

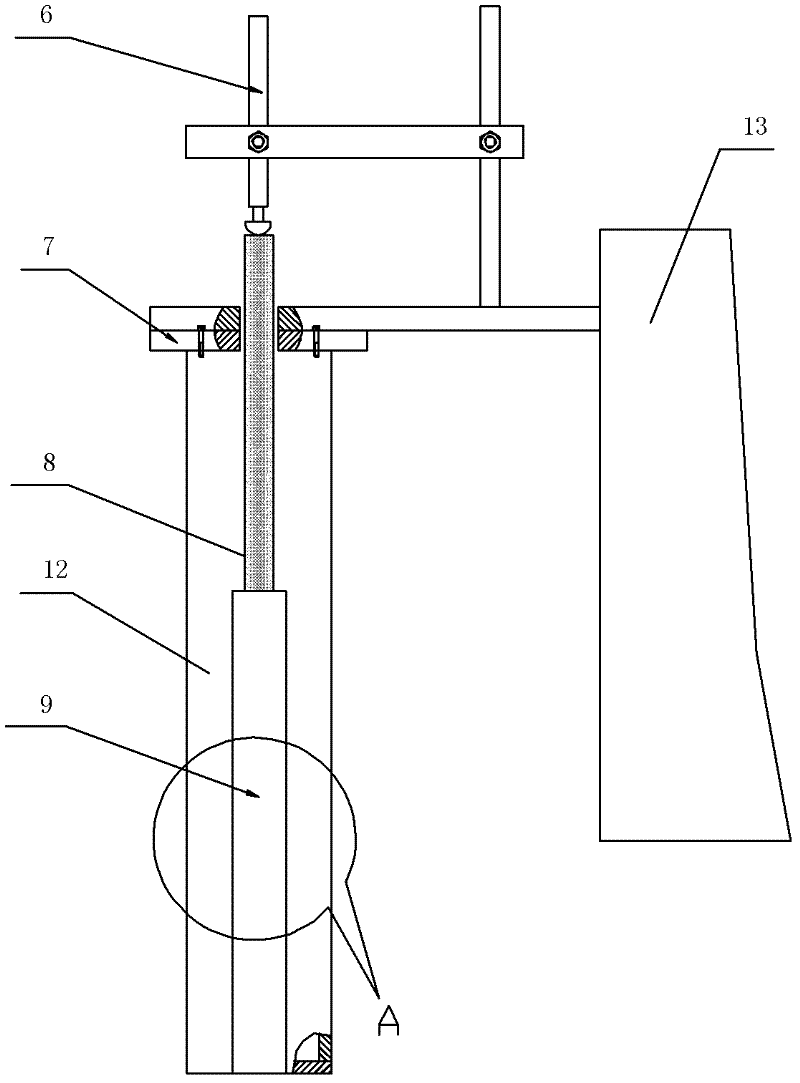

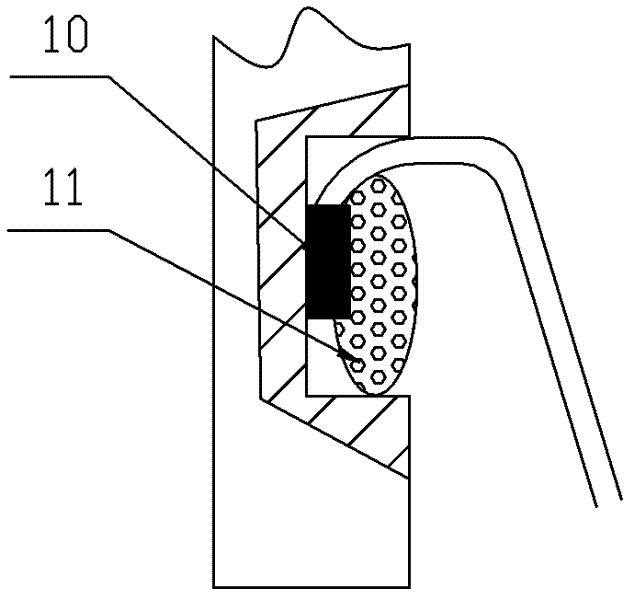

[0020] The cement emulsified asphalt mortar thermal deformation testing device provided by the present invention consists of a specimen support 5, a push rod 8, a fixed support 13 and a lifting device, a temperature chamber 12, a temperature sensor 10, a displacement sensor 6, a data acquisition module and a temperature controllable The external circulation system of high and low temperature tank is composed.

[0021] The test piece bracket 5 and the push rod 8 are made of quartz glass, and the push rod 8 passes through the top surface of the fixed support 13 to contact the test piece 9, and transmits the deformation of the test piece 9 to the displacement sensor 6. The fixed bracket 13 is suspended on the electric lifting slide bar, so that the fixed bracket 13 can vertically descend or rise out of the temperature chamber 12 . The displacement sensor 6 is fixed on the fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com