Novel quartz metal halide lamp

A metal halide lamp and quartz technology, which is applied to the parts and components of gas discharge lamps, can solve the problems of high working environment temperature, shortened life, color drift, etc. The effect of high lumen maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

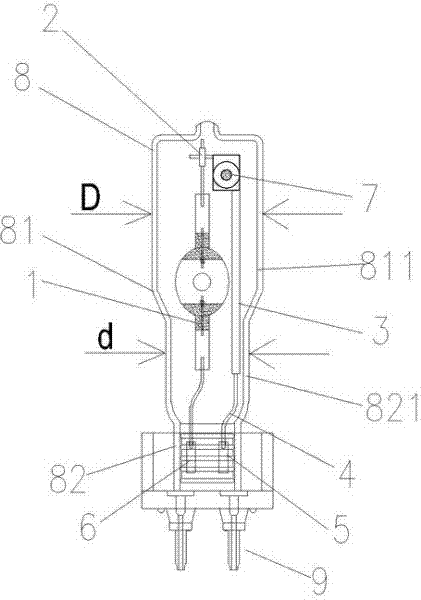

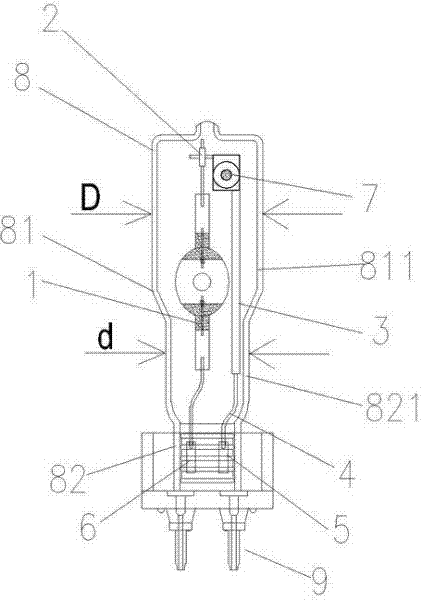

[0011] Such as figure 1 As shown, a new type of quartz metal halide lamp in this embodiment includes an arc tube 1, a nickel sleeve 2, a ceramic tube 3, a bracket 4, a first molybdenum sheet assembly 5, a second molybdenum sheet assembly 6, and a gas getter 7 , quartz tube 8 and lamp holder 9; wherein one end of the arc tube 1 is set with a nickel sleeve 2, the support 4 is set with a ceramic tube 3, and the nickel sleeve 2 is connected with one end of the support 4 by spot welding; the other end of the support 4 is connected with The first molybdenum sheet assembly 5 is spot-welded, and the support 4 is spot-welded with a getter 7; the other end of the arc tube 1 is spot-welded with the second molybdenum sheet assembly 6; the first molybdenum sheet assembly 5 and the second molybdenum sheet assembly 6 are packaged in the base 82 of the quartz tube 8 through glass; and the first molybdenum sheet assembly 5 and the second molybdenum sheet assembly 6 are fixed on the lamp cap 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com