Slide structure, support structure and seismically isolated structure

A supporting device and structure technology, which is applied in the fields of sliding structures, supporting devices and shock-proof structures, can solve the problems of increased manufacturing costs, and achieve the effects of reducing material costs, suppressing deformation, and lowering prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

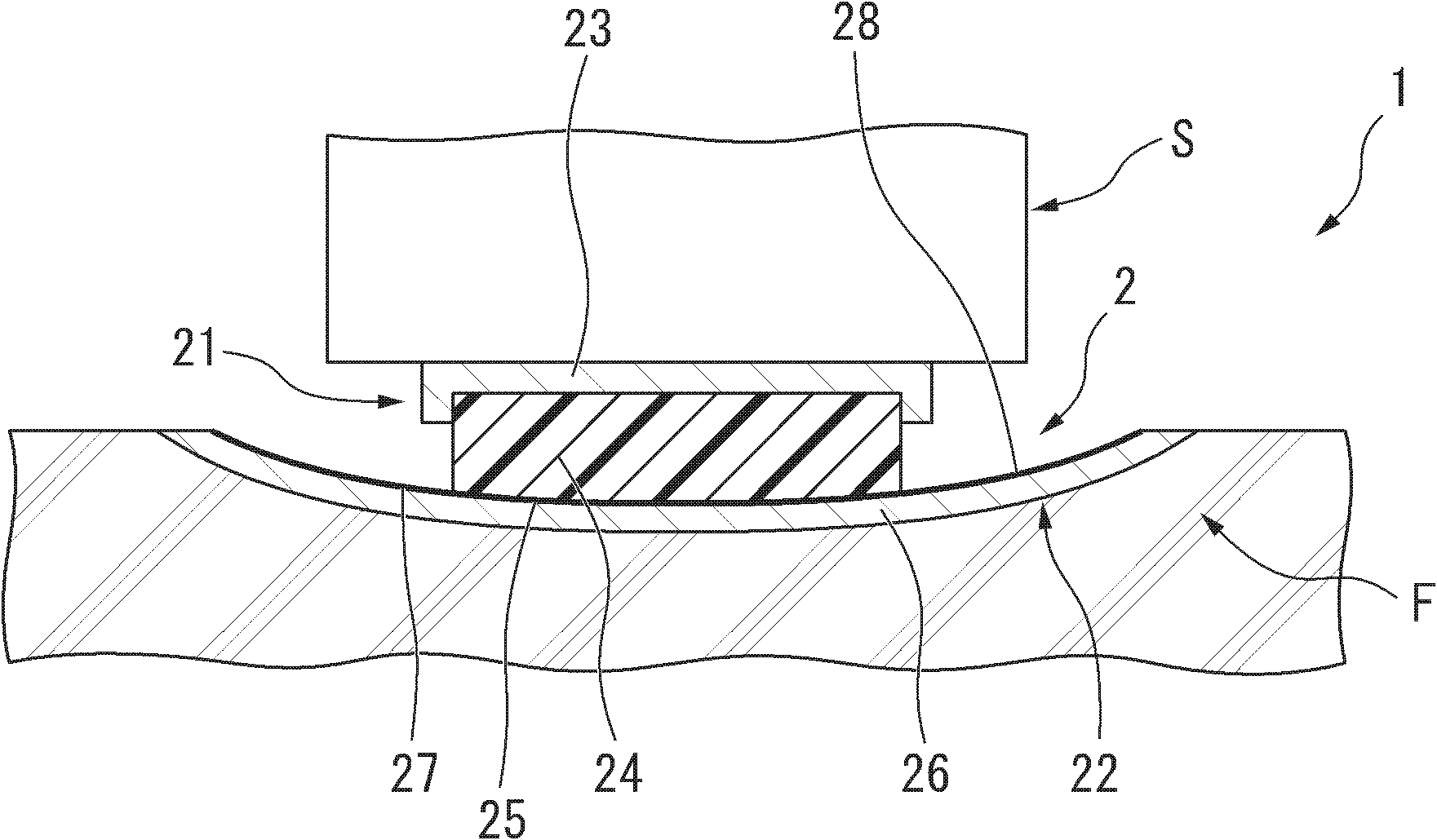

[0070] For the above-mentioned sliding support portion 2, test bodies (Examples 1 to 4) in which the conditions of the sliding member 21, the counterpart member 22, and the lubricant were set as shown in Table 1 below were prepared, and the surface of the counterpart member 22 was produced. The test bodies (comparative examples 1 and 2) under different conditions were subjected to a constant-velocity alternating cyclic load test.

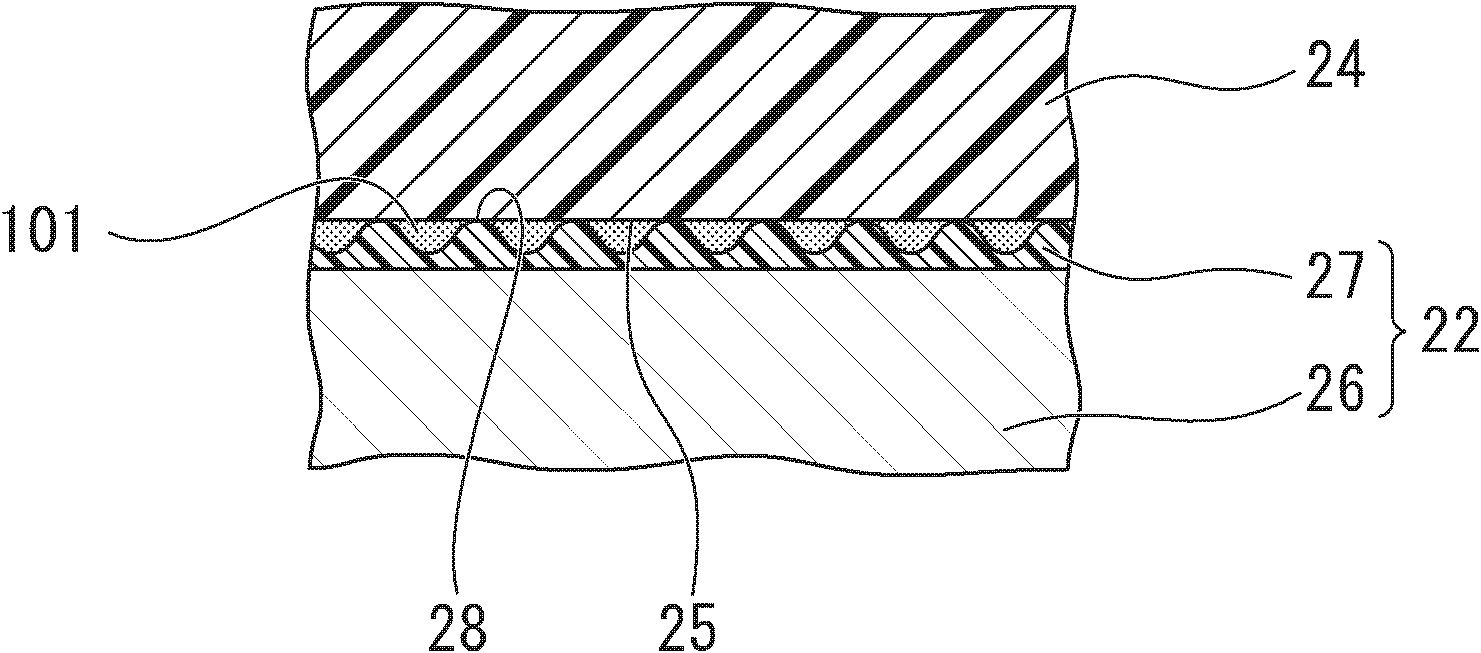

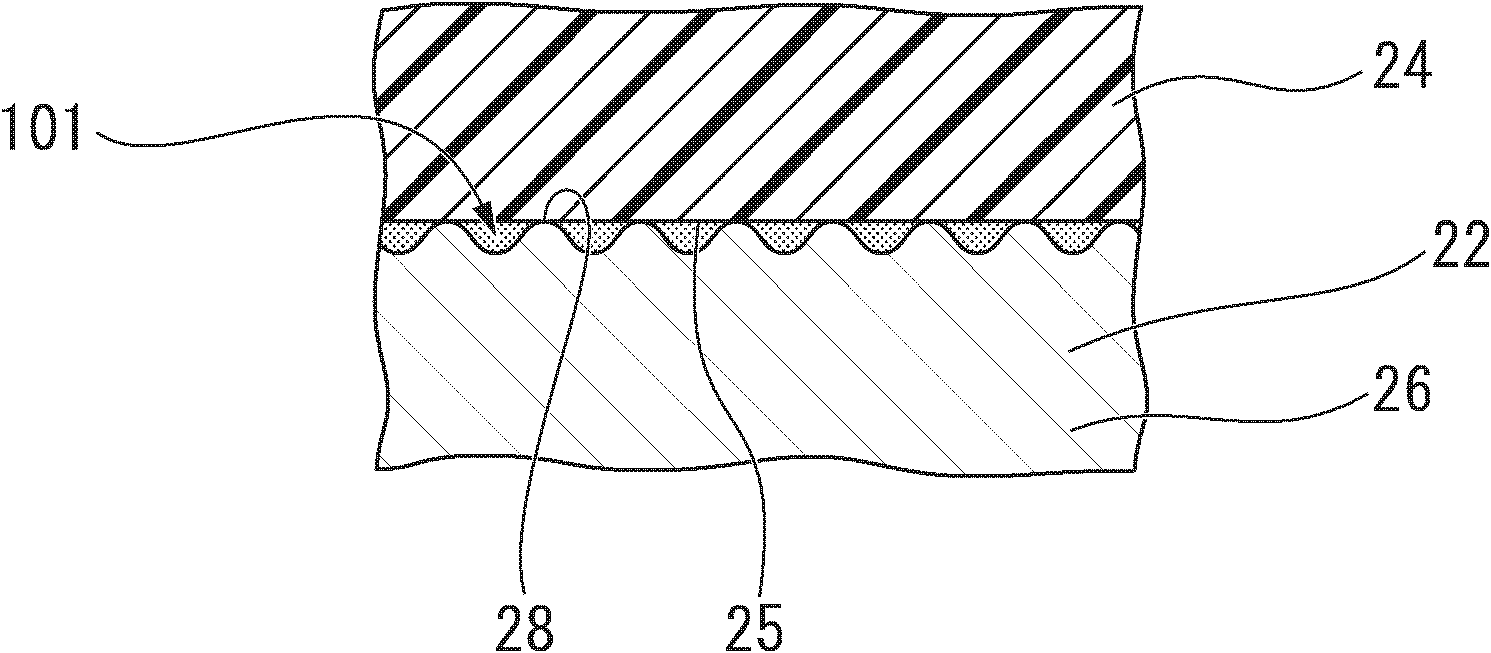

[0071]Here, in each test body of Examples 1 to 4 and Comparative Examples 1 and 2, the sliding member 21 is made of tetrafluoroethylene resin with a filler added, and has a diameter dimension φ of 100 mm and a thickness dimension of 4 mm. The disc-shaped sliding member body 24 has a Young's modulus of 600 MPa. In addition, in the test bodies of Examples 1 to 4, the opposite member 22 was constituted by spraying epoxy resin paint on the surface of the opposite member main body 26 made of a steel plate to form a film 27, and the film thickness of the ...

no. 2 example

[0092] In the second experimental example, as the sliding member main body 24 of the sliding member 21, as in the first experimental example, a filler made of tetrafluoroethylene resin with a Young's modulus of 600 MPa and a diameter φ of 600 mm was used. , A disk-shaped sliding member main body 24 having a thickness dimension of 4 mm. In addition, as the counterpart member 22, as in the first experimental example, a member having a film 27 formed by spraying an epoxy resin material on the surface of a steel plate was used. The film thickness of the film 27 was 250 μm, and the Young's modulus of the film 27 is 5GPa. Furthermore, as a result of measuring the maximum height Rz (JIS B0601-2001 / ISO 4287) of the surface of the film 27 (second sliding surface 28), as shown in Table 3, when the reference length is 0.8 mm, Rz is 10.2 μm; when the reference length is 2.5 mm, Rz is 18.5 μm; when the reference length is 8 mm, Rz is 39.2 μm. In addition, as a lubricant, silicon grease h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com