Flat plate turbulence type dynamic membrane separation device and membrane separation method thereof

A separation equipment and membrane separation technology, which is applied in the field of membrane separation, can solve the problems of high machining accuracy and operation and maintenance requirements of external power components, increase equipment operation and maintenance costs, and many structural restrictions, so as to suppress the growth of filter cake layer, Ease of replacement and cleaning, ease of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 flat-panel turbulence type dynamic membrane separation equipment

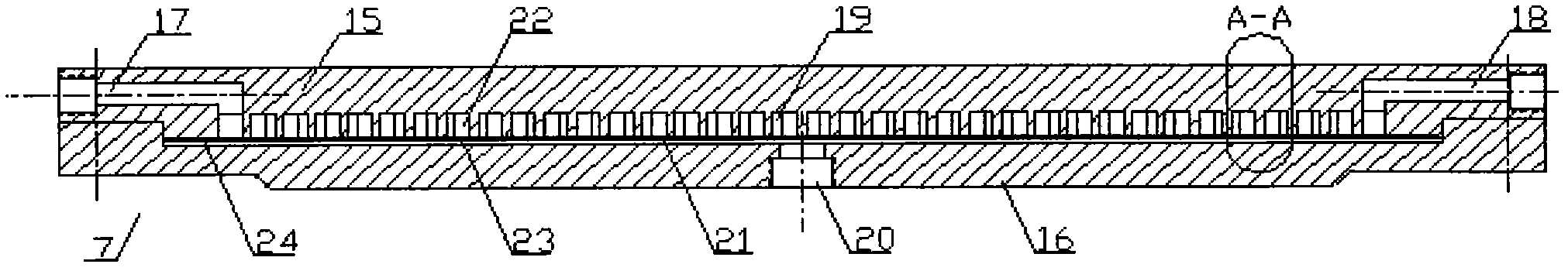

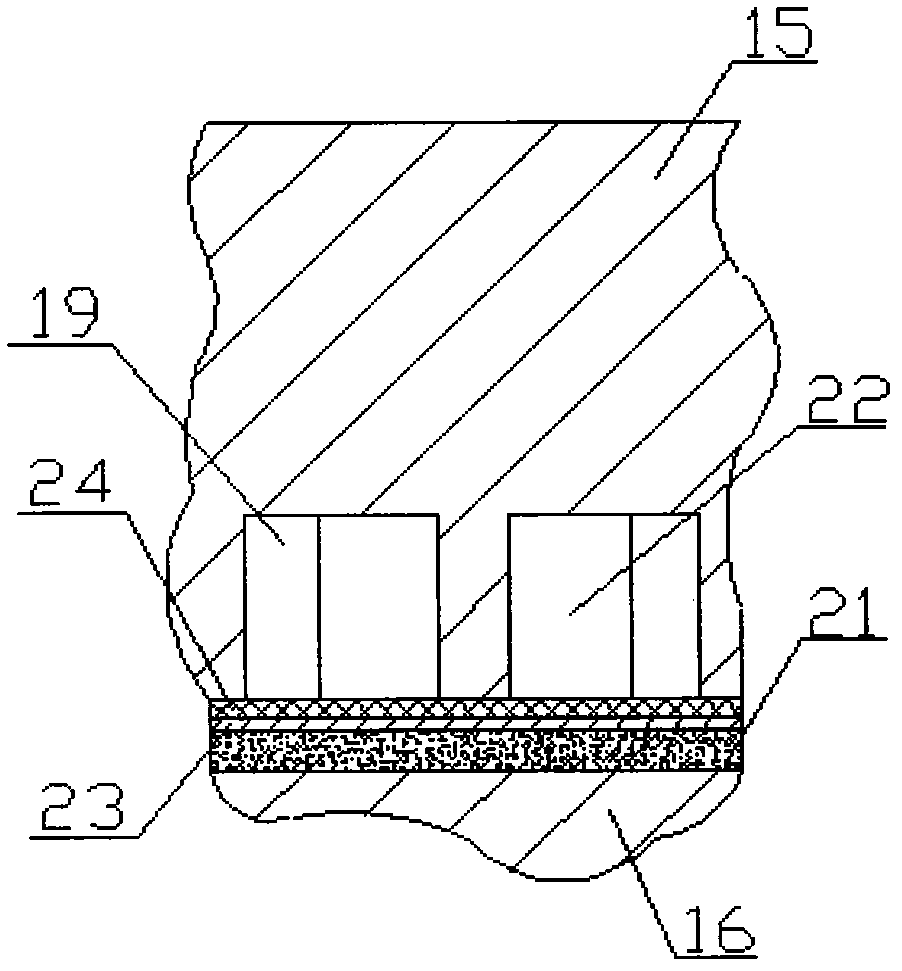

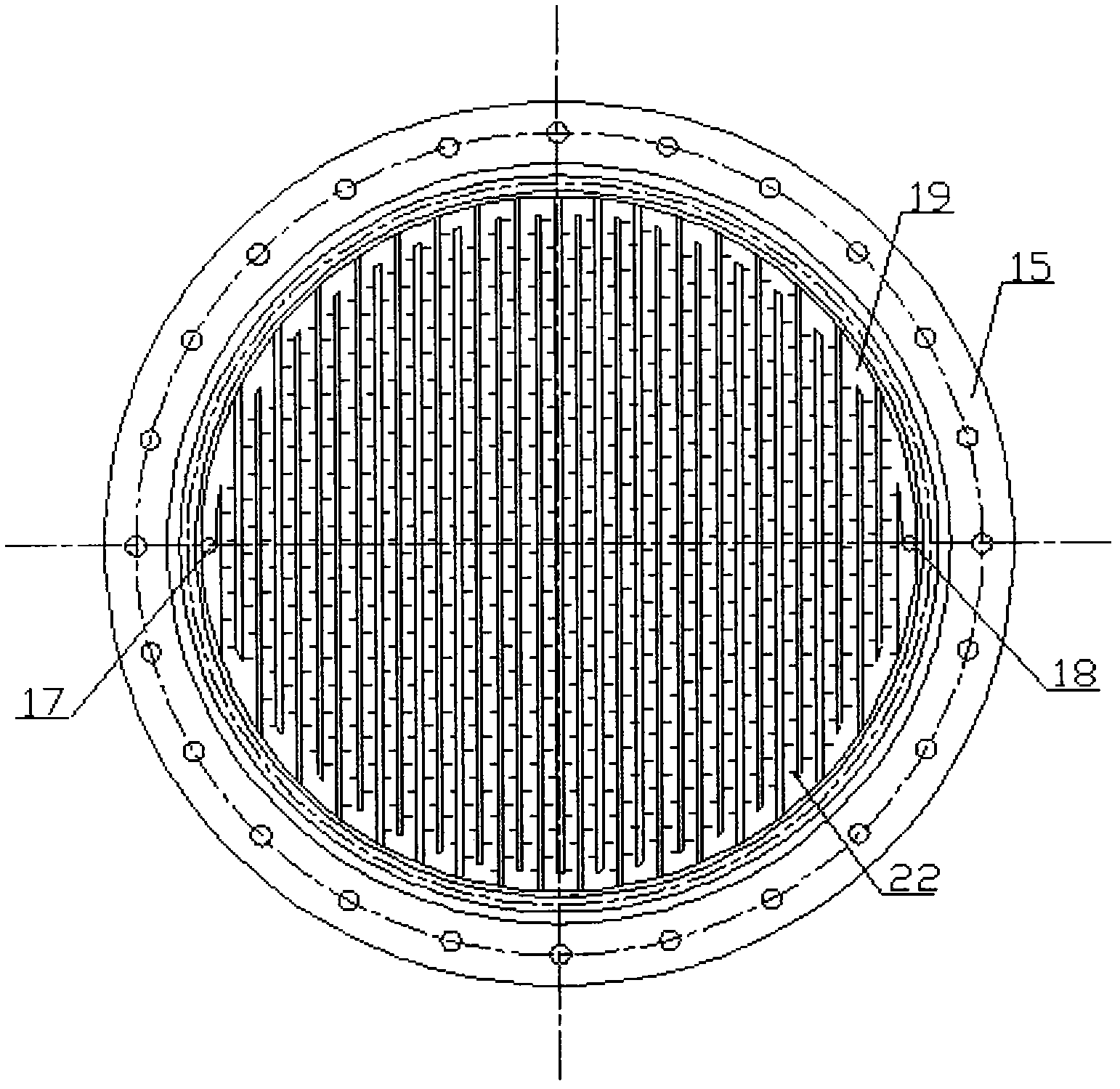

[0034] Such as figure 1 , the flat-panel turbulent dynamic membrane separation device 7 includes an upper cover plate 15 and a lower cover plate 16, and the upper and lower cover plates are fastened by bolts. combine figure 1 with figure 2 , the two ends of the upper cover plate 15 are provided with a liquid inlet 17 and a concentrated liquid port 18, and the upper cover plate 15 is provided with a zigzag groove 19 to form a reciprocating baffle flow channel, and the head and tail of the groove 19 are respectively connected with the liquid inlet 17 is connected with the dope port 18, if the disturbing flow part 22 is set in the groove 19, the spoiling part 22 can be disassembled freely, and the spoiling part 22 can adopt a spiral spoiling part, a baffle type spoiling part or a wave spoiling part. stream components, see Figure 4a with Figure 4b . The central position below the lower ...

Embodiment 2

[0039] Embodiment 2 membrane separation method

[0040] Such as Image 6 As shown, the raw water in the water inlet device 1 and the medicinal solution in the dosing device 3 are transported to the mixing device 6 through the water inlet pump 2 and the dosing pump 4 respectively, and the raw water and the medicinal solution complete the mixing process in the mixing device 6. After mixing The feed liquid enters the membrane separation device 7 through the liquid inlet 17 of the flat-panel turbulent dynamic membrane separation device 7, and flows through the surface of the filter screen 24 and the membrane 23 through the reciprocating zigzag flow channel formed by the groove 19, and the feed liquid Under the joint action of the filter screen 24, the reciprocating zigzag flow channel and the interfering flow member 22 added in the flow channel, the fluid generates strong turbulent flow, which hinders the adsorption and deposition of suspended particles and colloidal substances in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com