Carton taking method and device for ceramic tile packaging machine

A packaging machine and carton technology, applied in packaging and other directions, can solve problems such as falling, packaging tile deviation, inaccurate positioning, etc., and achieve the effects of simplifying the structure, reducing the length of the floor, and reducing the floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

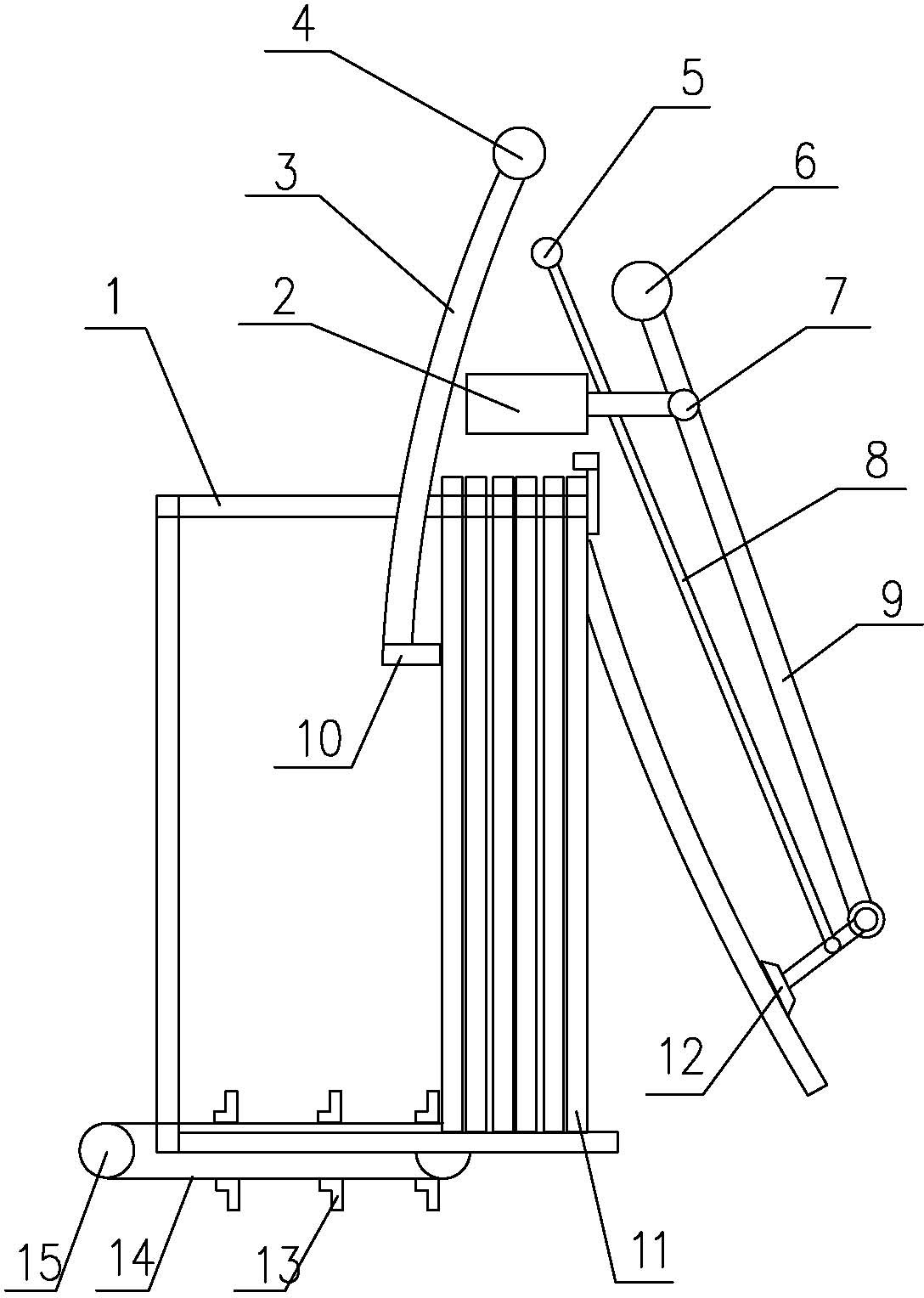

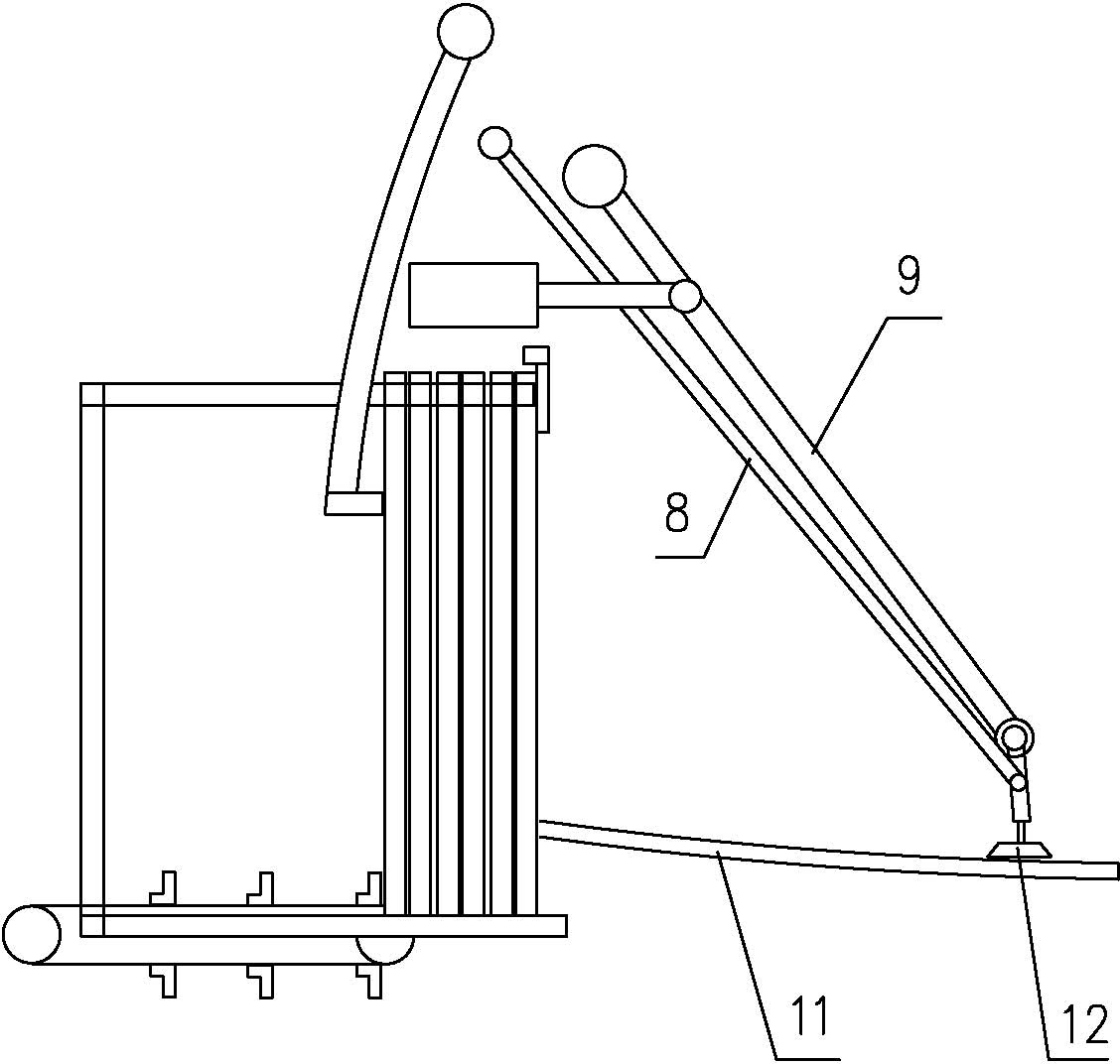

[0026] Such as Figure 4 As shown, carton bins 1 are arranged at the front, rear, left, and right sides of the tile packaging station 19, and a carton motion photoelectric sensor is set at a position behind the front end of the carton bin. Such as figure 1 As shown, the carton 11 is placed in the carton warehouse 1, the carton suction frame 9 is connected on the frame, the carton suction frame 9 is connected with the frame by the hinge 6, and the carton suction frame 9 can swing around the hinge 6.

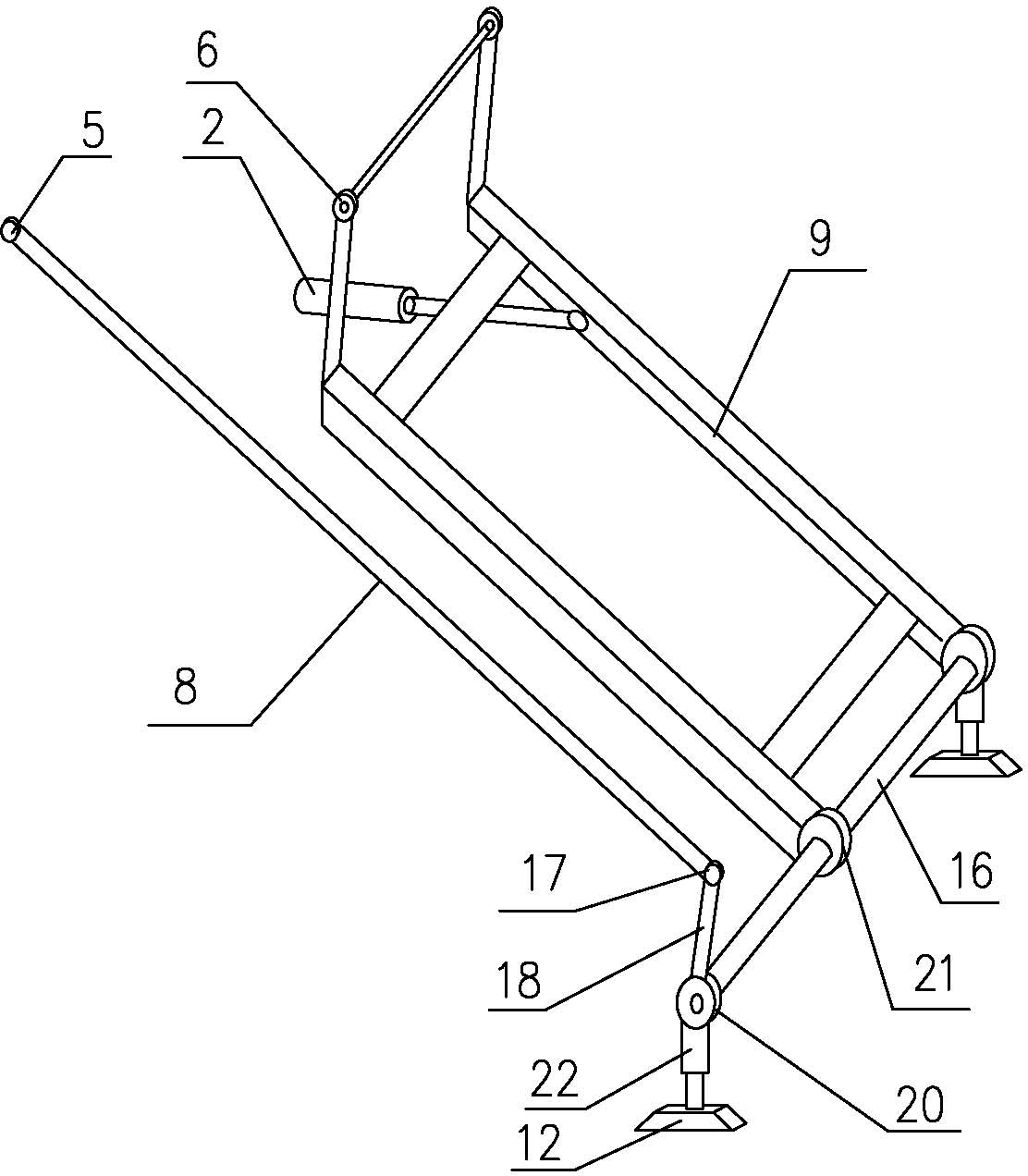

[0027] Such as image 3 As shown, the lower end of the carton suction frame 9 is fixed with a coupling sleeve 21, and a through shaft 16 is worn in the coupling sleeve 21. A coupling sleeve 20 is fixed at the end of the through shaft 16, and a separation cylinder 22 is fixed on the coupling sleeve 20, and the suction cup is connected with the separation cylinder 22. A suction cup motion photoelectric sensor is placed on the suction cup 12. The upper position of the carton suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com