Photosynthetic bacteria curing particles and preparation method thereof

A photosynthetic bacteria and particle technology, applied in biochemical equipment and methods, chemical instruments and methods, microorganism-based methods, etc., can solve the problem of insufficient concentration of photosynthetic bacteria solidified particles, poor adhesion of photosynthetic bacteria solidified particles, and purification effect. problems such as poor settlement, to achieve the effects of rapid settlement, low production cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method for photosynthetic bacteria solidified particles, comprising the steps of:

[0025] a, adding diatomaceous earth into the photosynthetic bacteria liquid, stirring, filtering, and preparing a photosynthetic bacteria concentrate with a water content of 50-60%;

[0026] b. Add diatomite and bentonite to the photosynthetic bacteria concentrate in a, stir, and prepare the photosynthetic bacteria material;

[0027] c. Granulating the photosynthetic bacteria material in b to obtain photosynthetic bacteria solidified granules.

[0028] Wherein, the weight ratio of the diatomite, bentonite and photosynthetic bacteria liquid is: 900-1000 parts: 30-50 parts: 1000 parts.

[0029] Wherein, the method of using the diatomite is as follows: in step a, 50-100 parts of the diatomite are added to the photosynthetic bacteria liquid, and in step b, the remaining diatomite is added to the photosynthetic bacteria concentrate.

[0030]...

Embodiment 1

[0045] The preparation of embodiment 1 photosynthetic bacteria immobilized particle

[0046] a. Add 50 kilograms of diatomite into 1000 kilograms of photosynthetic bacteria liquid, stir fully, so that diatomite can fully absorb photosynthetic bacteria, filter with 0.001-0.1 micron PP hollow fiber ultrafiltration membrane, and obtain photosynthetic bacteria with a water content of 50%. bacterial concentrate;

[0047] B, 850 kilograms of diatomite, 30 kilograms of bentonite are added in the photosynthetic bacteria concentrated solution that step a obtains, stir, obtain the photosynthetic bacteria material with water content at 6%;

[0048] c. According to the mass of each photosynthetic bacteria solidified particle is 5g, the volume is 3cm 3 According to the standard, the photosynthetic bacteria material obtained in step b is granulated with a roller granulator to obtain the photosynthetic bacteria solidified granules.

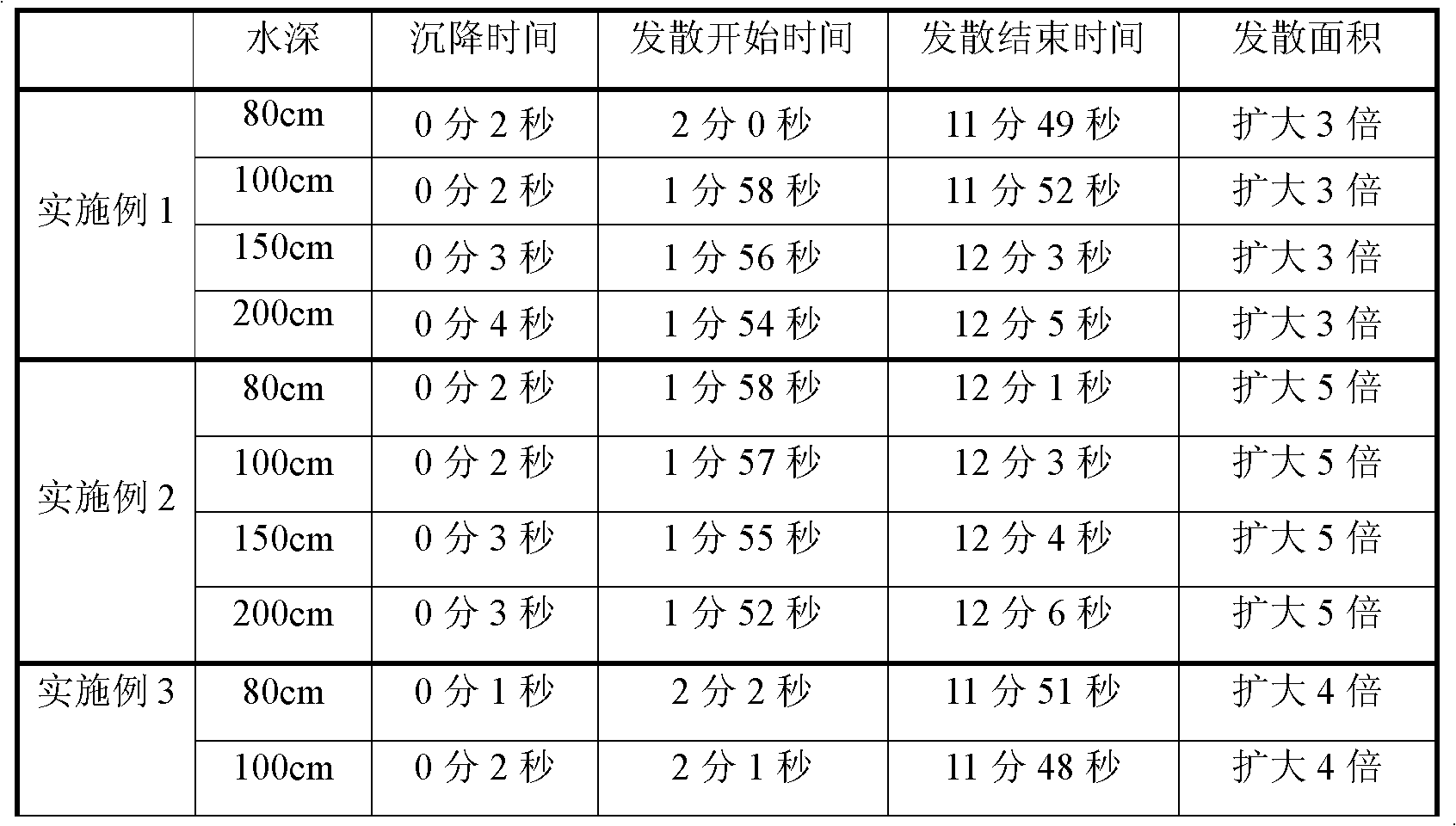

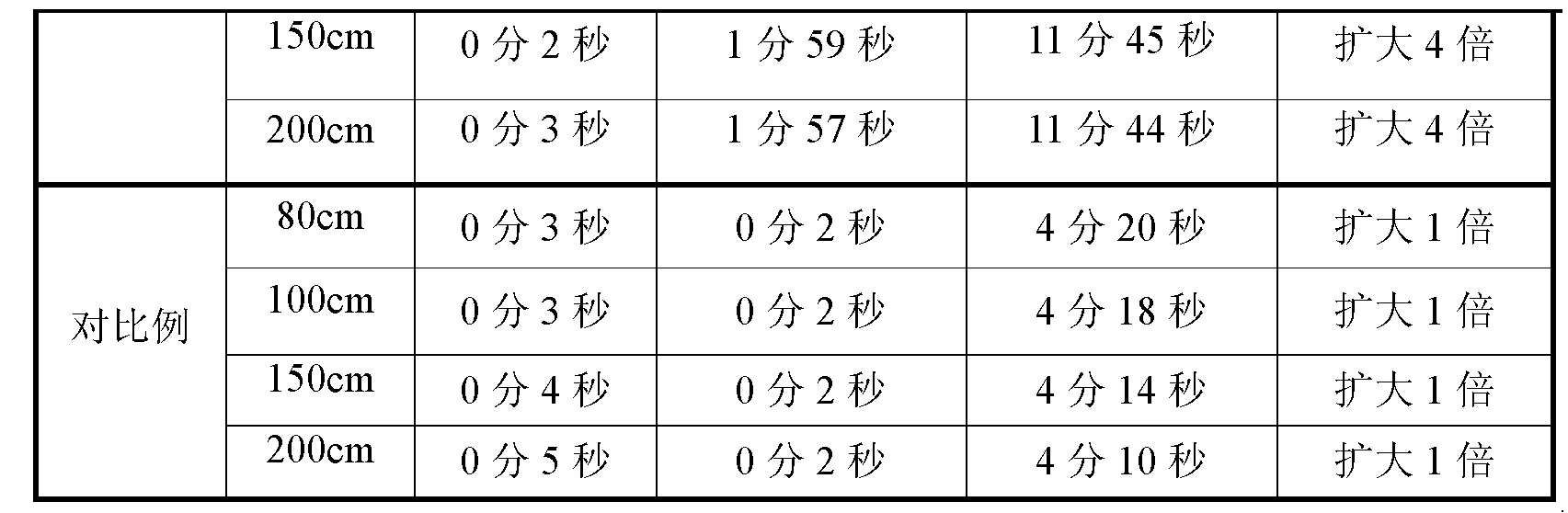

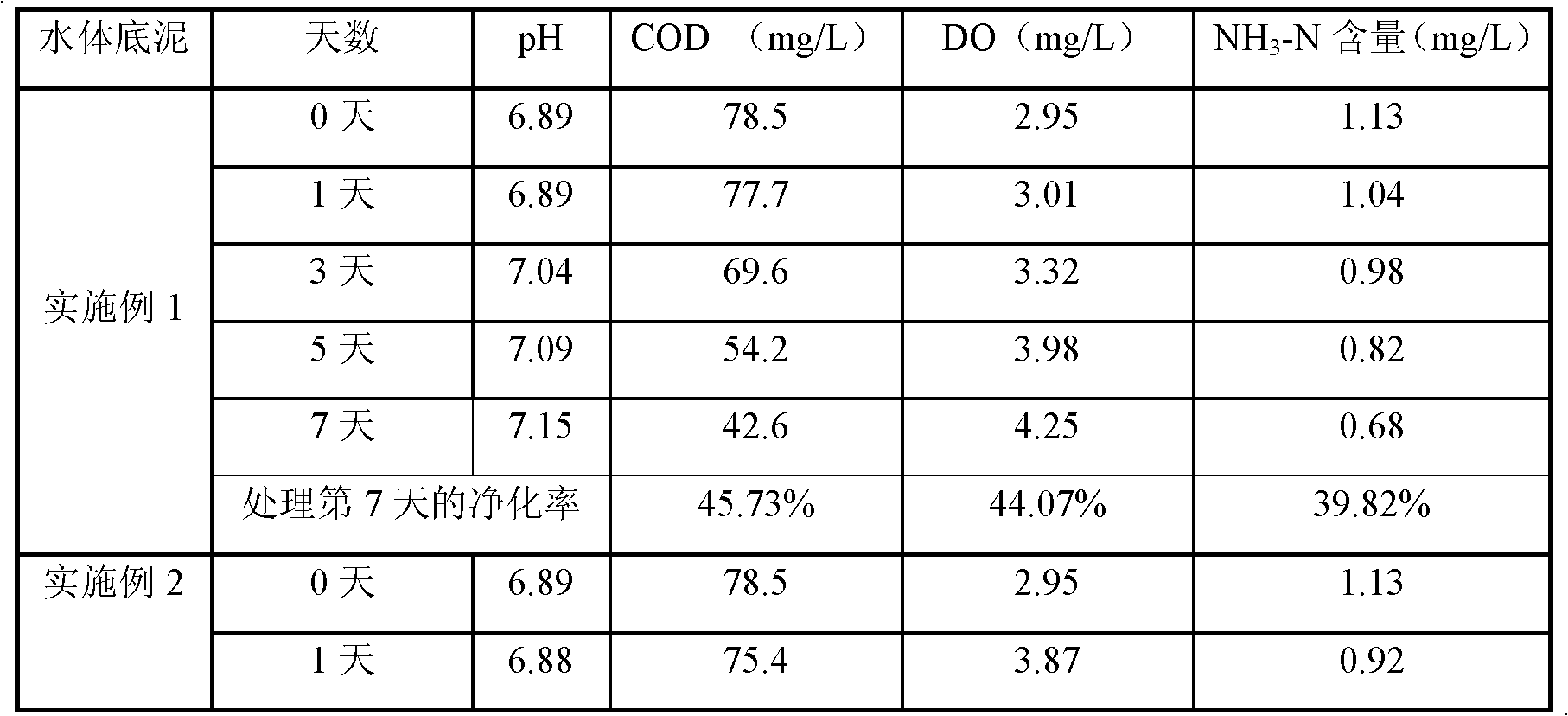

[0049] The settling time, divergence start time, diverge...

Embodiment 2

[0050] The preparation of embodiment 2 photosynthetic bacteria solidified particles

[0051] a. Add 50 kilograms of diatomite into 1000 kilograms of photosynthetic bacteria liquid, stir fully, so that the diatomite powder can fully absorb photosynthetic bacteria, and filter with 0.001-0.1 micron PP hollow fiber ultrafiltration membrane to obtain water content of 55%. photosynthetic bacteria concentrate;

[0052] B, 900 kilograms of diatomaceous earth, 30 kilograms of bentonite are added in the concentrated photosynthetic bacteria that step a obtains, stir, obtain the photosynthetic bacteria material with water content at 5.8%;

[0053] c. According to the mass of each photosynthetic bacteria solidified particle is 5g, the volume is 3cm 3 According to the standard, the photosynthetic bacteria material obtained in step b is granulated with a roller granulator to obtain the photosynthetic bacteria solidified granules.

[0054] The settling time, divergence start time, divergenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com