Novel shear wall with wood frame

A shear wall and wood frame technology, applied in the field of wood processing, can solve the problems of poor energy dissipation capacity, wall hysteresis loop pinch, loss of connection capacity, etc., to achieve good stress and deformation capacity, increased bearing capacity, cost reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

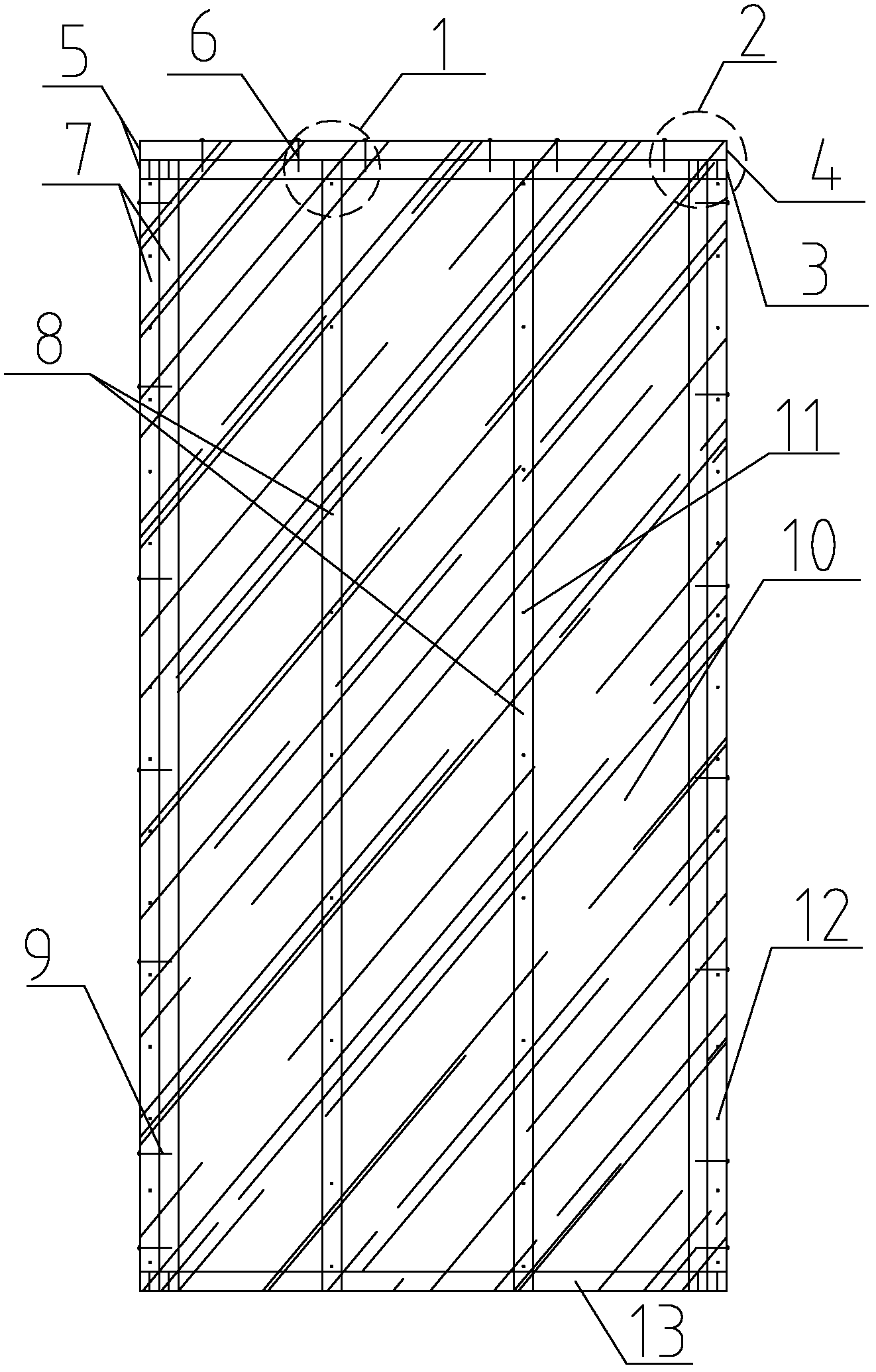

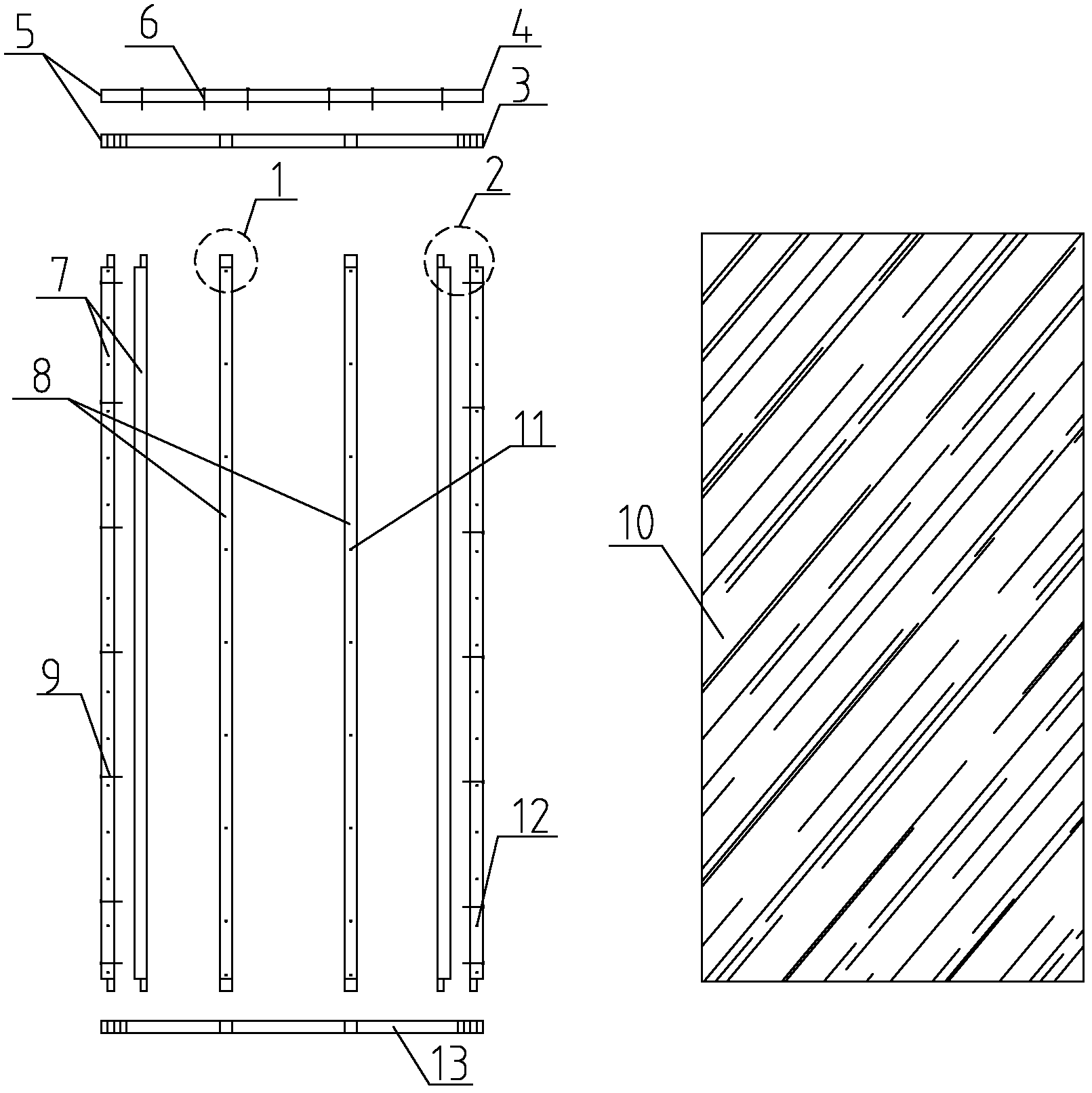

[0040] This embodiment provides a wood frame shear wall, which is composed of a cladding panel 10 and a wall frame. The cladding panel 10 is fixed to the side of the wall frame by nails. figure 1 and figure 2 shown.

[0041] Above-mentioned wall frame is made up of top beam plate 5, wall stud and bottom beam plate 13, wherein, roof beam plate 5 is double-layer, and it comprises upper roof beam plate 4 and lower roof beam plate 3, and the two are nailed together, The wall studs include edge studs (double studs on both sides of the wall) 7 and middle studs 8, and the edge studs 7 are double studs nailed together by two standard timbers, and the two are nailed together;

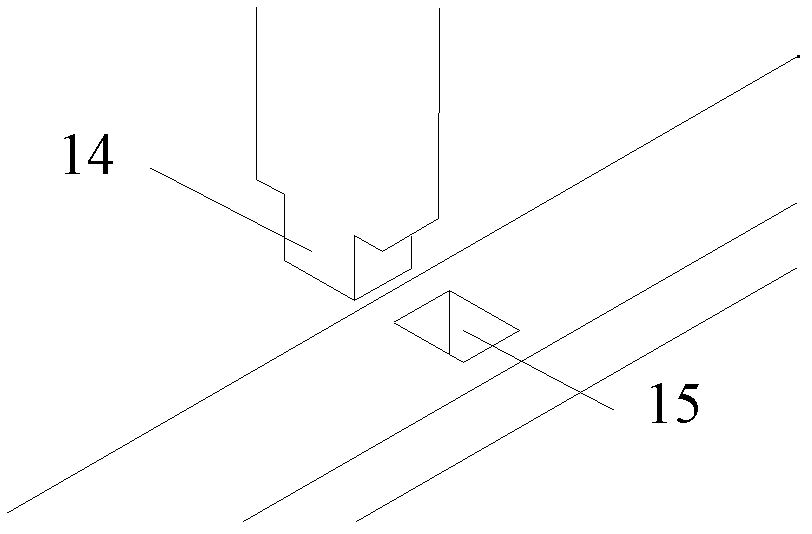

[0042] The edge wall studs 7 and the middle wall studs 8 are arranged between the top beam plate 5 and the bottom beam plate 13 at intervals, and the two ends of the edge wall studs 7 and the middle wall studs 8 pass through the lower top beam plate 3 and the bottom beam plate 13 Mortise and tenon connection,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com