Field installation method for vertical-shaft wind-driven generator

A technology for wind turbines and on-site installation, which is applied to wind turbine components, wind engines, and wind engines at right angles to the wind direction. Simplicity, reduced manufacturing cost and transportation cost, and reduced difficulty in maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

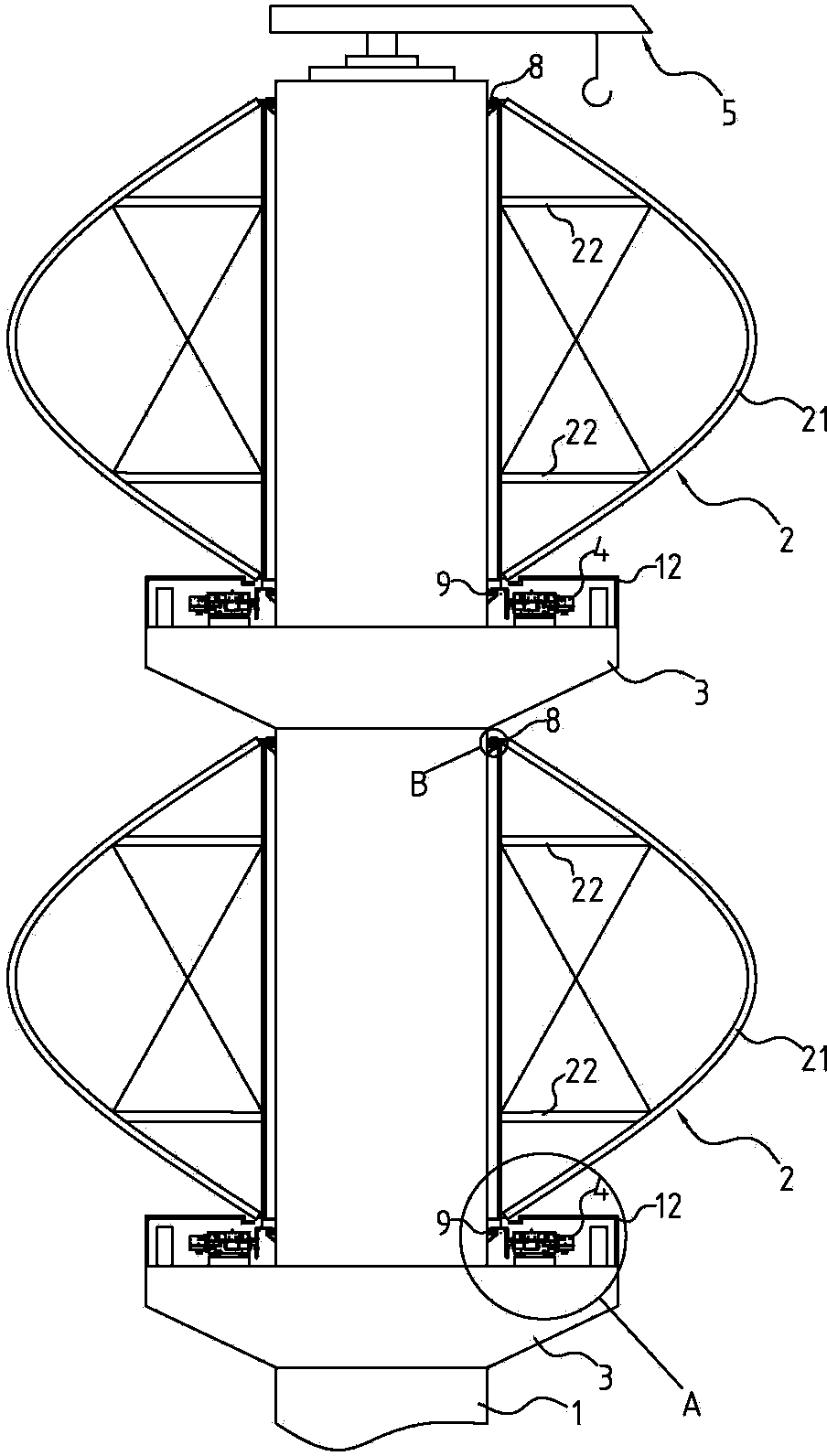

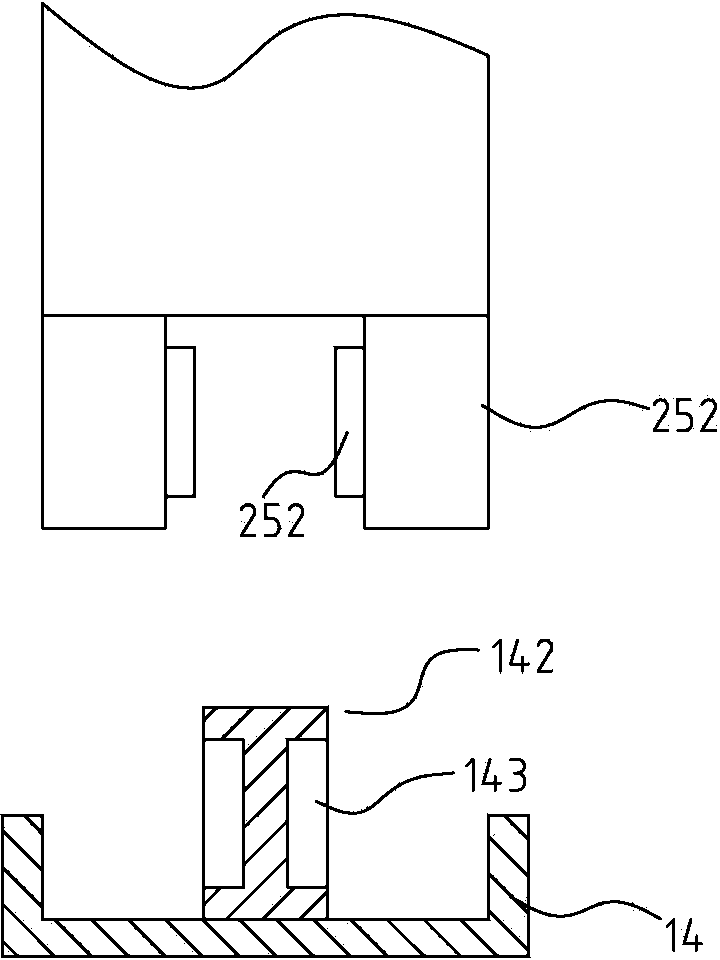

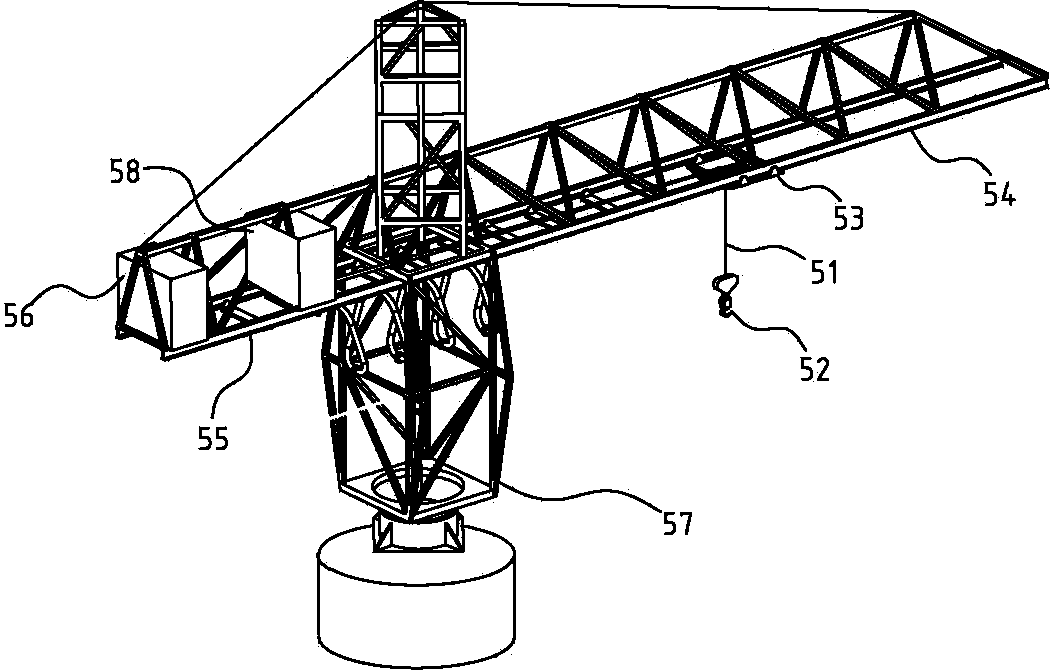

[0042] Such as figure 1 As shown, a vertical axis wind power generator includes a central tower column 1 on which more than two power generation units are arranged. In this embodiment, the central tower column 1 is a hollow reinforced concrete center A tower column 1, the central tower column 1 is provided with two power generation units arranged up and down. The power generation unit includes a wind wheel 2 , a main gear 10 , and more than two generators 4 . In this embodiment, two generators 4 are arranged symmetrically around the main gear 10 ; the wind wheel 2 is a Φ-shaped wind wheel, and the wind wheel 2 is composed of two symmetrically arranged blades 21 . Such as image 3 , 4 As shown, the central tower 1 is provided with a first bearing 8 corresponding to the upper end of the wind wheel 2 , and the central tower 1 is provided with a second bearing 9 corresponding to the lower end of the wind wheel 2 . The upper end of the blade 21 is connected to the outer ring of...

Embodiment 2

[0065] This embodiment is basically the same as Embodiment 1, except that three power generation units arranged up and down are arranged on the central tower.

[0066] In addition, in the above-mentioned embodiments 1 and 2, the gear transmission system can also be any other combination of gears that can play a transmission role. For example, the gear transmission system includes a pinion, a worm gear and a The pinion is engaged, the shaft of the pinion is provided with a worm gear, and the shaft of the generator 4 placed horizontally is provided with a worm, and the pinion is connected with the shaft of the generator 4 through the structure of the worm gear and worm. The vertical rotation of the wheel 2 is transformed into the horizontal rotation of the generator 4, and for the vertical axis wind power generator 4, the installation of the generator 4 is simpler and more convenient.

[0067] The reinforced concrete central tower column adopted by the invention is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com