Low-noise forward multi-wing centrifugal blower

A centrifugal fan and multi-blade technology, applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems that the noise index cannot meet the needs of fan development, and the noise control methods are limited, so as to achieve sound absorption Good sound insulation effect, good airflow performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

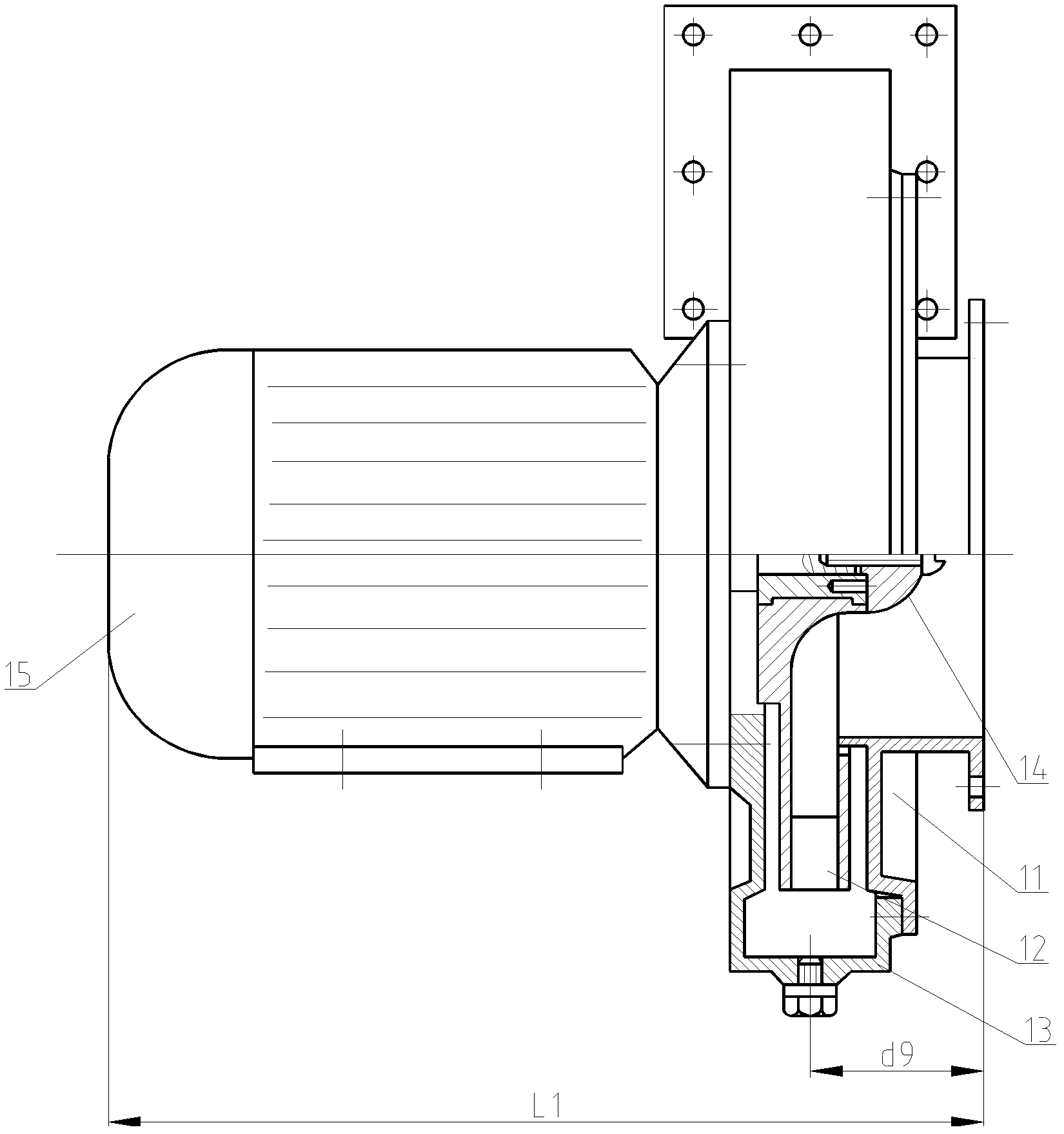

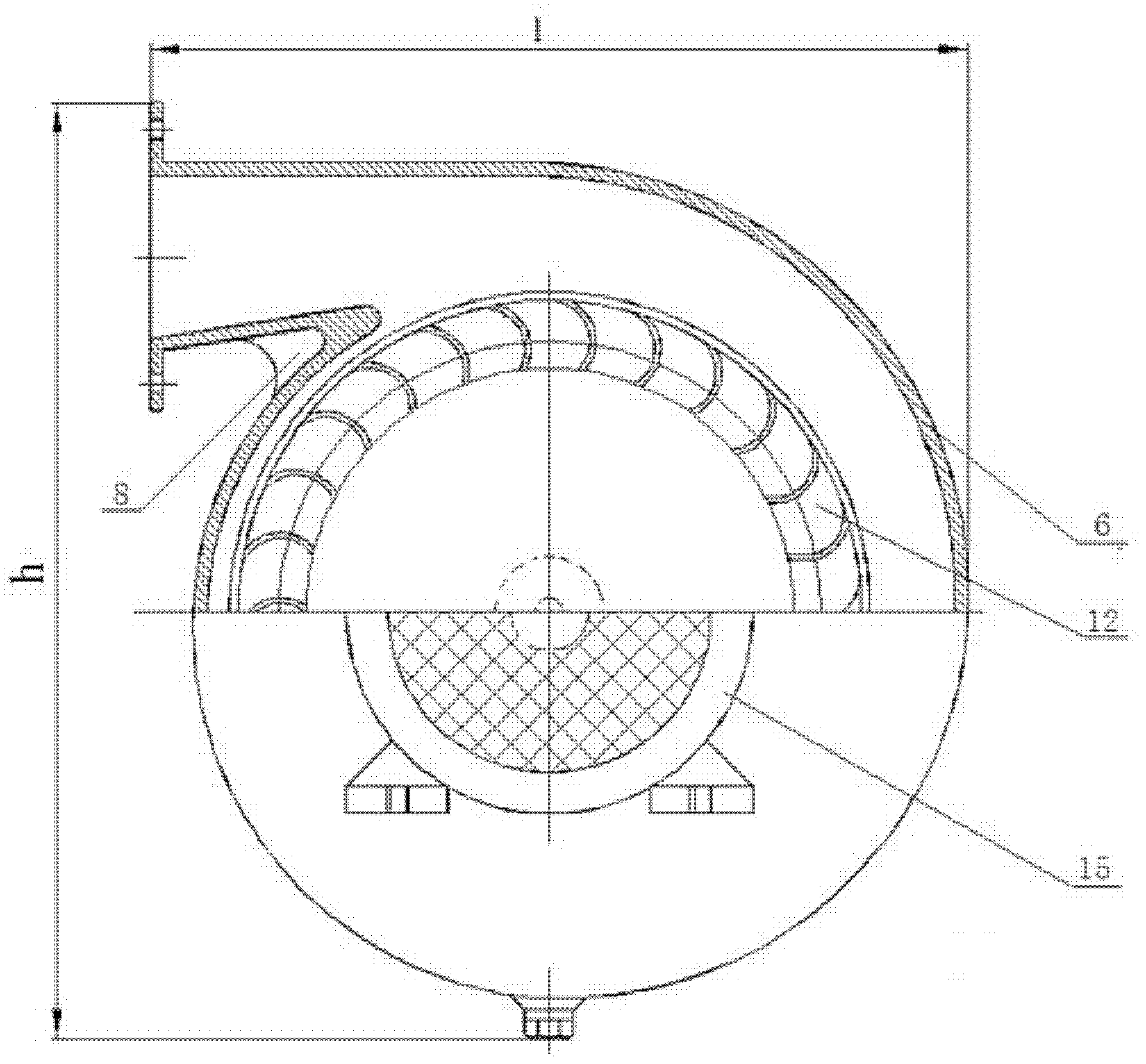

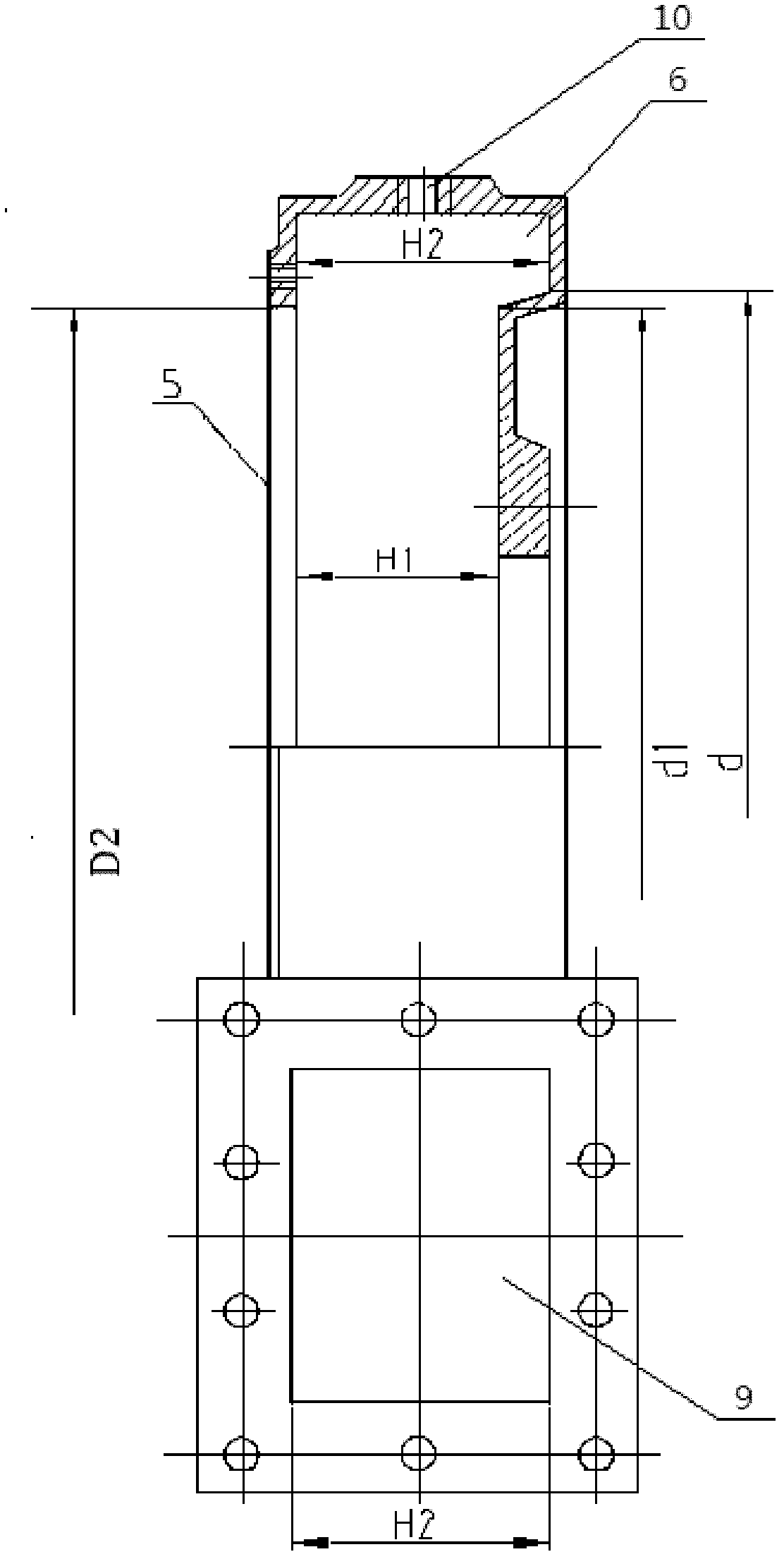

[0025] It includes a volute 13, an impeller 12 installed in the volute, a current collector 11 installed in the air inlet of the volute, and a motor 15 that drives the impeller to rotate. The rotating shaft of the motor penetrates into the volute and connects with the impeller 12. The front plate of the impeller faces the outer base plate inward, and is fastened by the impeller gland 14. The current collector 11 is connected to the end surface of the other side of the volute. couplet. The overall length L1 of the fan is 290mm, the height h is 335mm, and the width 1 is 300mm. Air enters through the air inlet of the collector 11 and is discharged from the square air outlet of the volute 9.

[0026] The impeller is a forward multi-blade narrow cavity impeller with a structure such as Figure 5 , 6 As shown, it includes a base plate 4 and a hollow front plate 2. The out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com