Special composite analog pavement for testing mechanical characteristics of tire

A technology of tire mechanical characteristics and composite simulation, applied in the field of simulated road surface required for tire mechanical test, can solve the problems of less recycling times, high test cost, large test tire wear, etc., and achieves good friction coefficient stability and repairability. Good performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

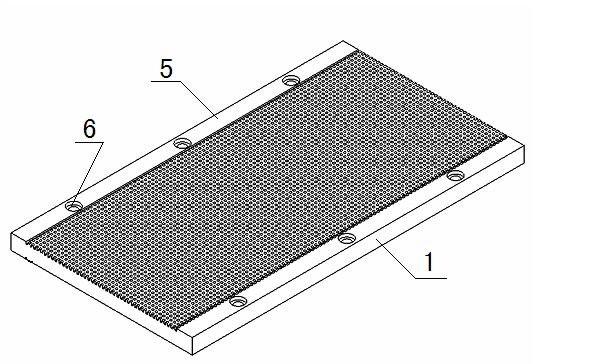

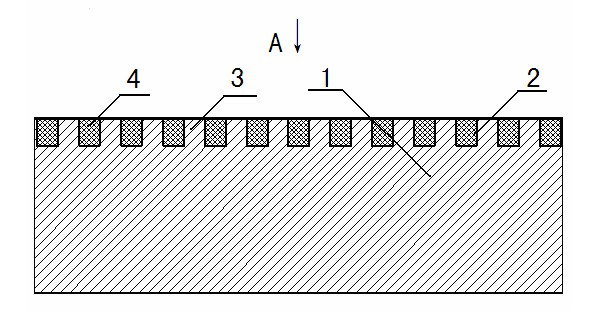

[0032] Such as figure 1 , 2 3. As shown in 3: Trial-manufacture three steel plate simulation pavements with a length of 1100mm and a width of 500mm to be used as the matrix of the composite simulated pavement. The complete simulated pavement is formed by splicing several fixed-length steel plate pavements. Grooves in both transverse and longitudinal directions are processed on three flat steel plates, and the grooves are parallel to each other and form bosses. The width of the groove is determined to be 6 mm, the depth is 8 mm, and the interval between the grooves is determined to be 5 mm. At the same time, the edges with a width of 50mm can be reserved on both sides of the simulated road surface of the steel plate without processing grooves. In the unprocessed area, the single pavement is divided into five equal parts, and three connection holes are processed at the two ends and the middle point to simulate the connection between the pavement and the test bench. Acco...

Embodiment 2

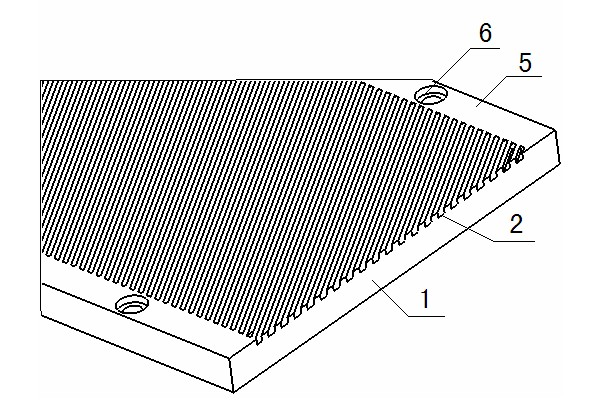

[0034] Such as Figure 4 , 5 Shown: Trial-manufacture three 1100mm long and 500mm wide steel plate simulated pavements as the matrix of the composite simulated pavement, and the complete simulated pavement is formed by splicing several fixed-length steel plate pavements. Grooves at 60° to the direction of the road surface are processed on three flat steel plates, and the grooves are parallel to each other and form bosses. The width of the groove is determined to be 6 mm, the depth is 10 mm, and the interval between the grooves is determined to be 6 mm. At the same time, the edges with a width of 50mm can be reserved on both sides of the simulated road surface of the steel plate without processing grooves. In the unprocessed area, the single pavement is divided into five equal parts, and three connection holes are processed at the two ends and the middle point to simulate the connection between the pavement and the test bench. According to the test requirements of tire...

Embodiment 3

[0036] Such as Figure 6Shown: Four steel plate substrates with a length of 1100mm and a width of 500m are trial-manufactured, and grooves in the transverse and vertical directions are processed on the four steel plates, and the width of the grooves processed on two steel plates is determined to be 4mm, and the depth is 10mm, the grooves are parallel to each other, and the distance between them is 5mm. The width of the processed grooves on the other two steel plates is determined to be 8mm, and the depth is 10mm. The grooves are parallel to each other, and the interval between them is 5mm. When the steel plate simulates the road surface, an edge with a width of 50 mm can be reserved without processing grooves. In the unprocessed area, the single pavement is divided into five equal parts, and three connection holes are processed at the two ends and the middle point to simulate the connection between the pavement and the test bench. According to the test requirements of tire m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com