Aramid fiber fabric reinforced wet friction material and preparation method thereof

A technology of wet friction material and aramid fiber, which is applied in the field of friction materials, can solve problems such as unstable friction coefficient, low friction coefficient, and high cost, and achieve good friction coefficient stability, vibration and noise improvement, and high shear strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the aramid fiber fabric reinforced wet friction material specifically includes the following steps:

[0044] Step 1: Add 100-200g of modified phenolic resin into 550ml of absolute ethanol, then stir for 4 hours, and let stand for 24 hours after stirring to obtain solution A;

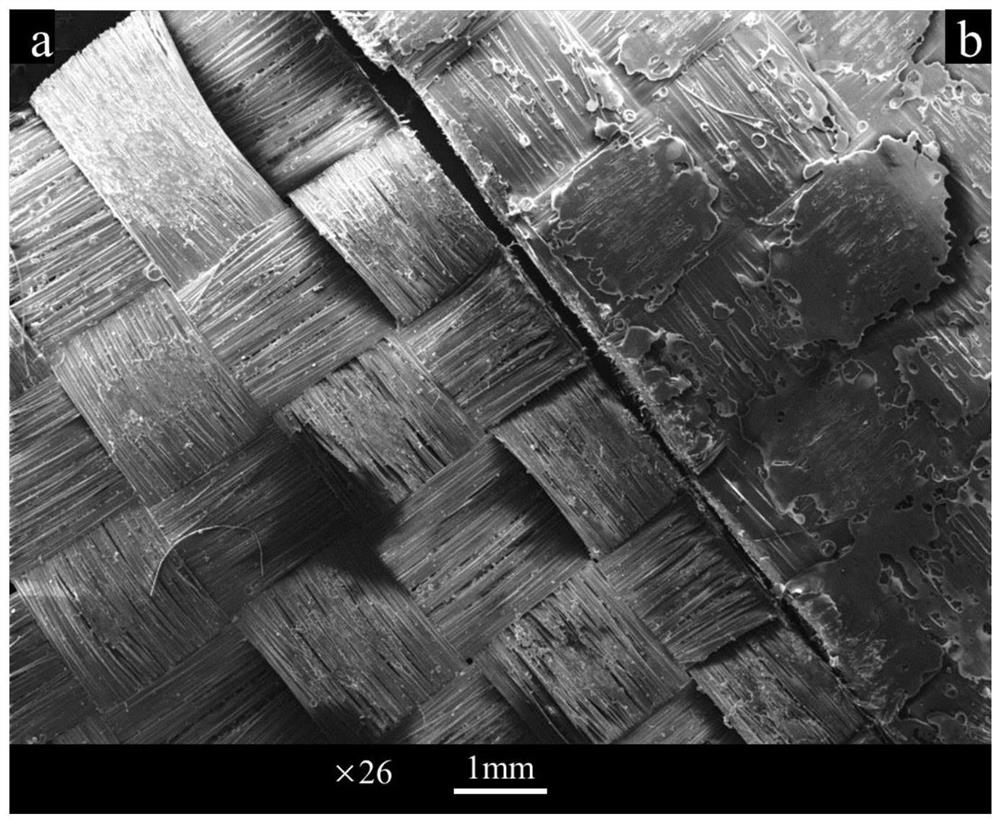

[0045] Step 2: Cut the aramid fiber fabric into a rectangular shape of 5cm×10cm and lock the edges with a thread. Put the locked aramid fiber fabric in a petri dish containing acetone for 24 hours, take it out, and dry it to get the sample A;

[0046] Step 3: Sample A is alternately washed several times with deionized water and absolute ethanol, and then dried at about 75°C for at least 10 hours to obtain sample B;

[0047] Step 4: Immerse sample B in solution A for a period of time, take out and air dry to obtain sample C;

[0048] Step 5: The sample C is placed on a vulcanizing machine to be hot-pressed to obtain an aramid fiber fabric reinforced wet friction material...

Embodiment 1

[0050] Step 1: Weigh the weight of each component of the wet friction material: 400 g of aramid fiber fabric, 100 g of cashew nut shell oil-modified phenolic resin, 300 g of anhydrous ethanol, and 250 g of acetone.

[0051] Step 2: Add 100g of modified phenolic resin into 550ml of absolute ethanol, then stir for 4 hours, and leave to stand for 24 hours after stirring to obtain solution A;

[0052] Step 3: Cut the aramid fiber fabric into a rectangular shape of 5cm×10cm and lock the edges with threads. Put the locked aramid fiber fabric in a petri dish filled with acetone for 24 hours, then take it out and dry it to get the sample A;

[0053] Step 4: Sample A is washed several times alternately with deionized water and absolute ethanol, and then dried at about 75°C for at least 10 hours to obtain sample B;

[0054] Step 5: Put sample B in solution A and place it together with the container in the vacuum box, set the pressure value within a certain range, take out and dry after...

Embodiment 2

[0058] Step 1: Weigh the weight of each component of the wet friction material: 400 g of aramid fiber fabric, 100 g of cashew nut shell oil-modified phenolic resin, 300 g of anhydrous ethanol, and 250 g of acetone.

[0059] Step 2: Add 200g of modified phenolic resin into 550ml of absolute ethanol, then stir for 4 hours, and leave to stand for 24 hours after stirring to obtain solution A;

[0060] Step 3: Cut the aramid fiber fabric into a rectangular shape of 5cm×10cm and lock the edges with threads. Put the locked aramid fiber fabric in a petri dish filled with acetone for 24 hours, then take it out and dry it to get the sample A;

[0061] Step 4: Sample A is washed several times alternately with deionized water and absolute ethanol, and then dried at about 75°C for at least 10 hours to obtain sample B;

[0062] Step 5: Immerse sample B in solution A for a period of time, take out and air dry to obtain sample C;

[0063] Step 6: The sample C is placed on a vulcanizing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

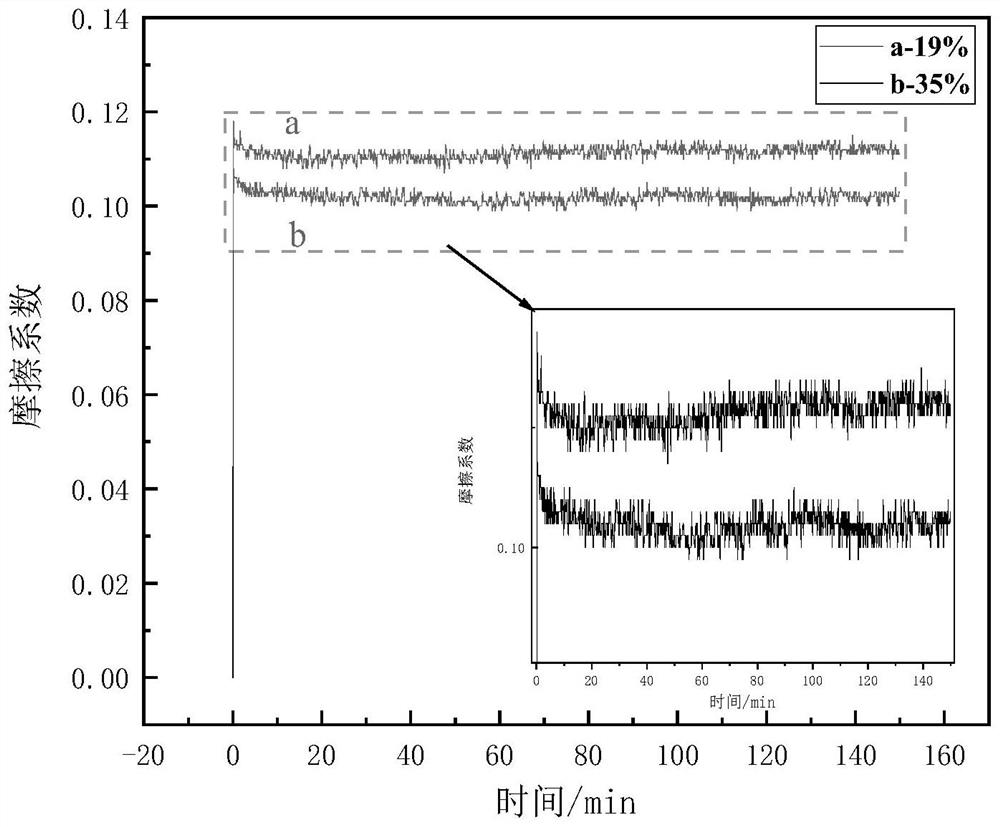

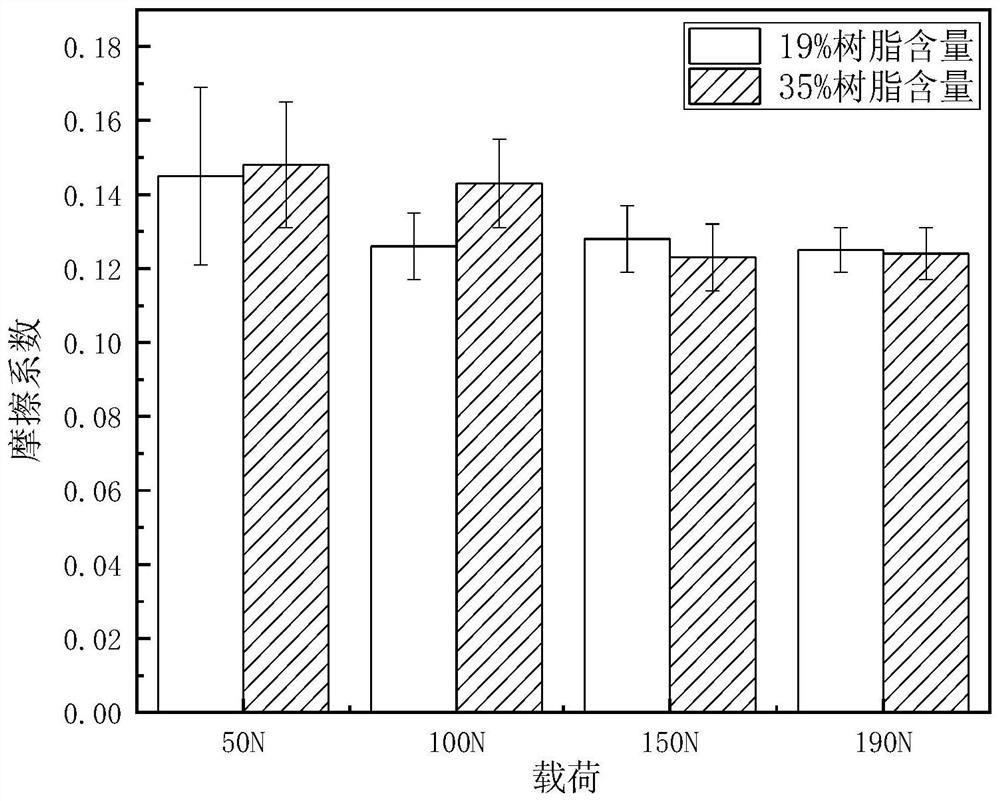

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com