Abrasive dust recycling method in brake disc production

A technology for processing and brake pads, applied to friction linings, mechanical equipment, etc., can solve the problems of wasting material resources and achieve the effects of improving economic benefits, reducing wear, and improving the stability of friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

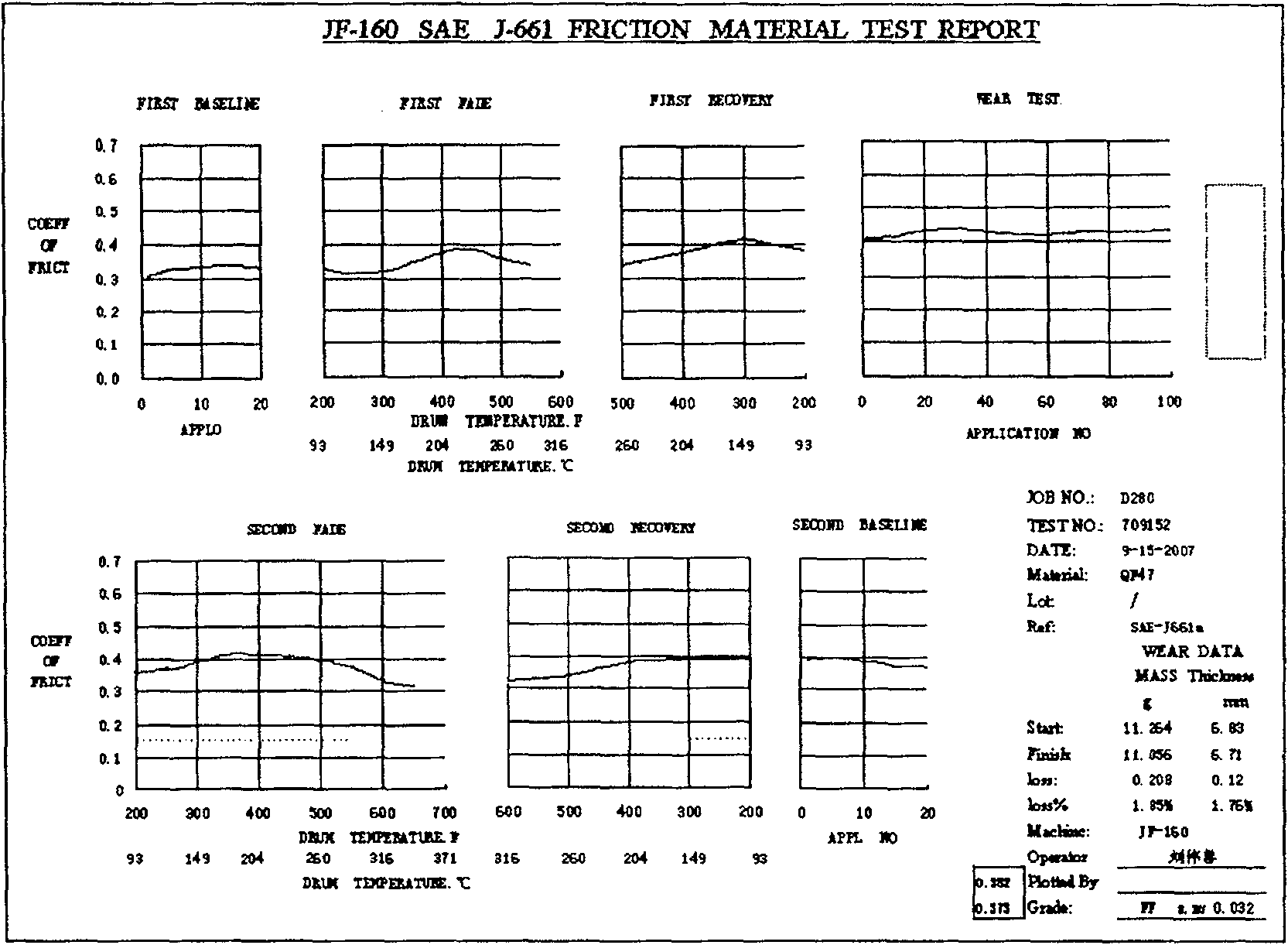

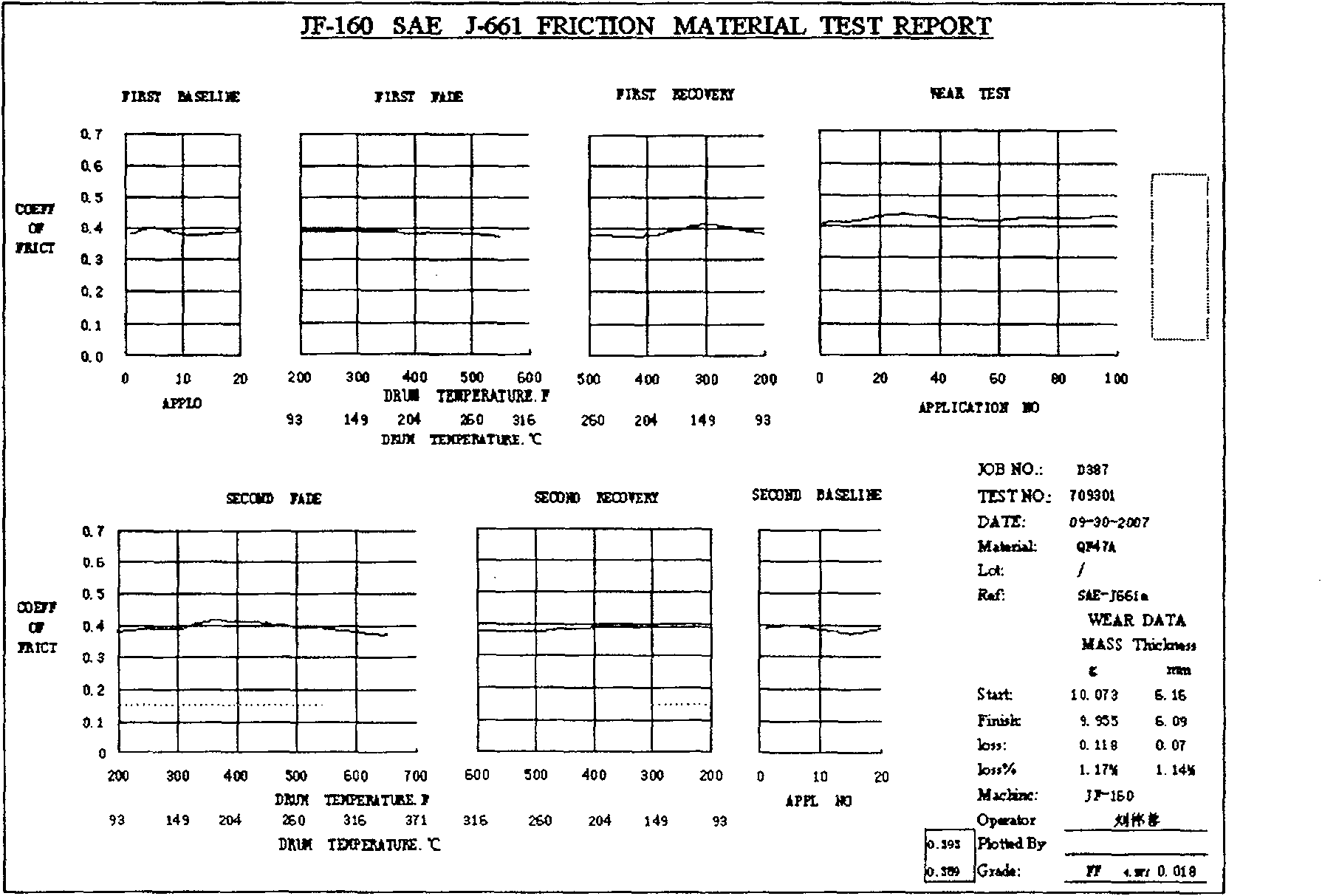

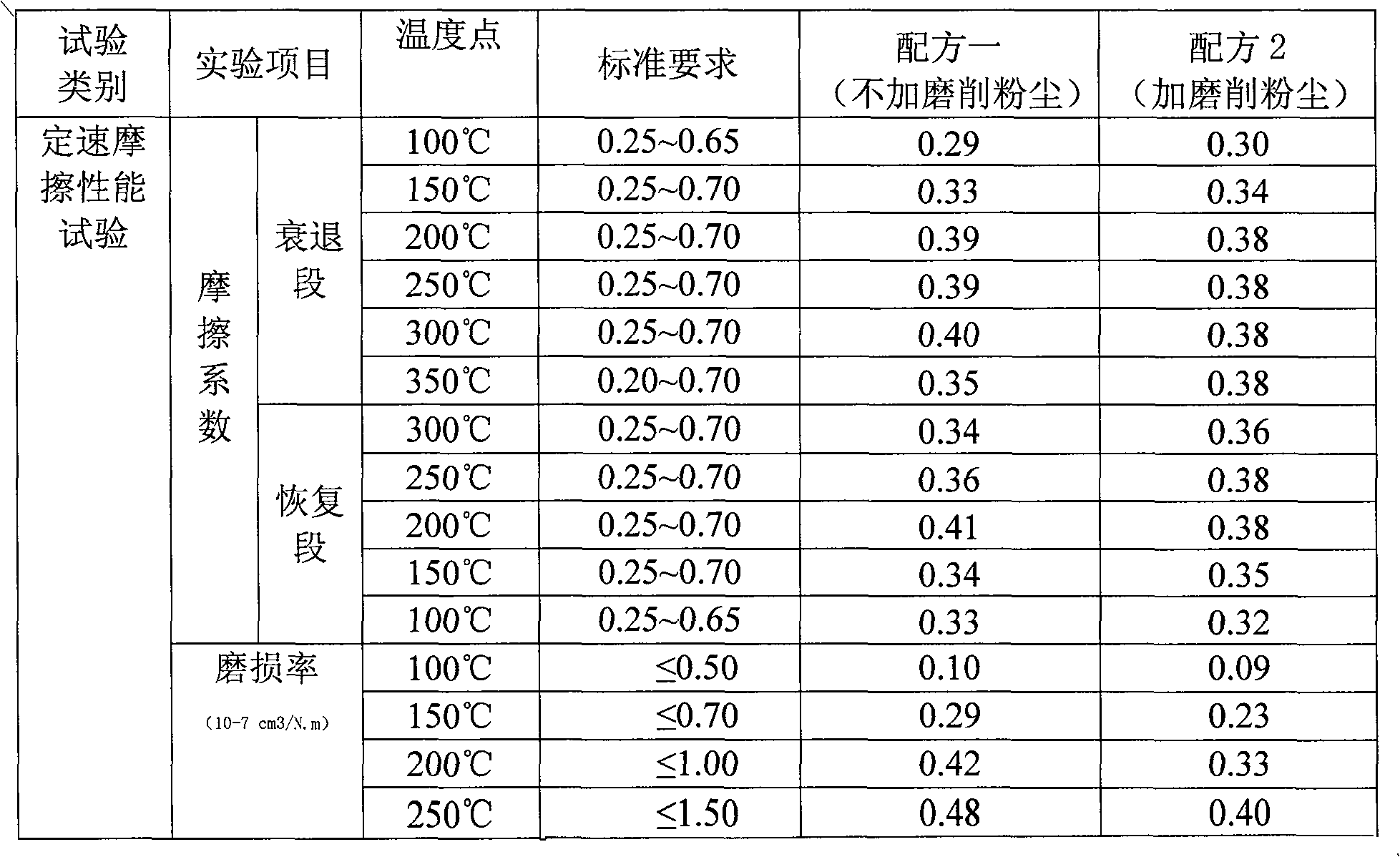

[0014] First weigh 1.5kg of phenolic resin, 1.0kg of nitrile rubber powder, 5.5kg of steel fiber, 1.75kg of -195 graphite, 1.5kg of artificial graphite, Al 2 o 3 0.125kg, BaSO 4 3.75kg, 8.125kg of grinding dust, poured into the plow mixer and stirred evenly for 5 minutes, made into a friction material containing grinding dust, then put it into the mold and pressed it for 8-10 minutes, and kept the unit pressure at 15-20Mpa After pressing and forming, take out the brake pads for heat treatment. The heat treatment procedure is 140°C for 1h, 165°C for 2h, 180°C for 2h, 195°C for 1h, and then cooled to room temperature, according to GB5763-1998 and SAE J661 standard procedures Constant speed and CHASE test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com