Abrasion-resistant material, preparation method of abrasion-resistant material and abrasion-resistant part

A technology of wear-resistant materials and wear-resistant agents, applied in the field of wear-resistant materials, can solve problems such as poor low-temperature performance, and achieve the effects of low operating temperature, controllable friction coefficient, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

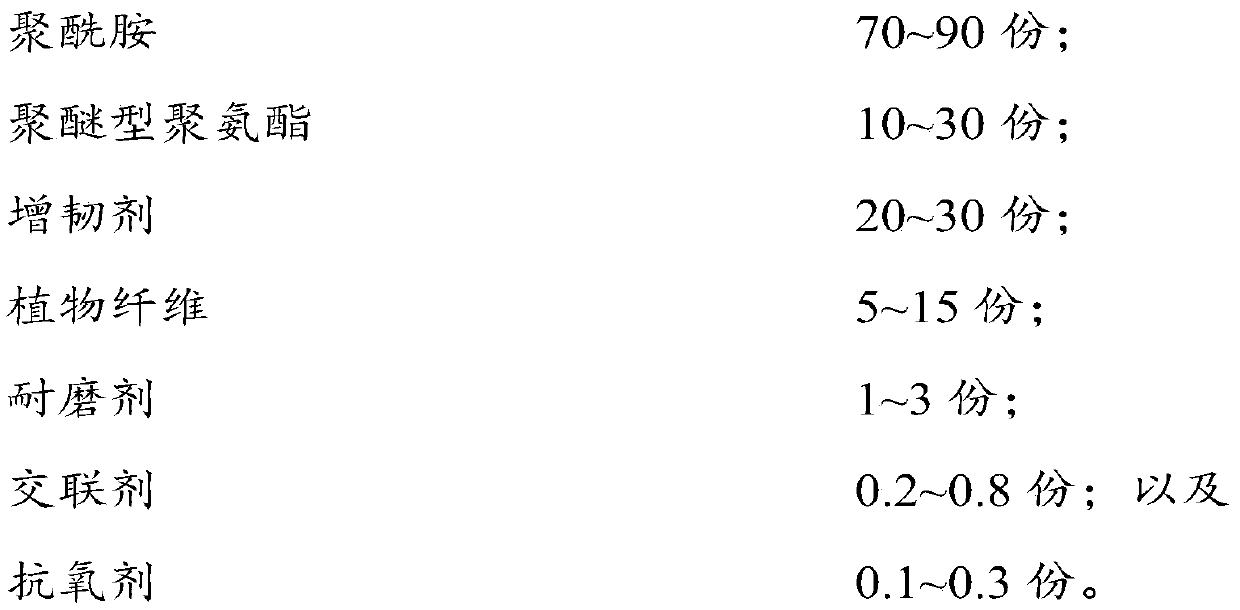

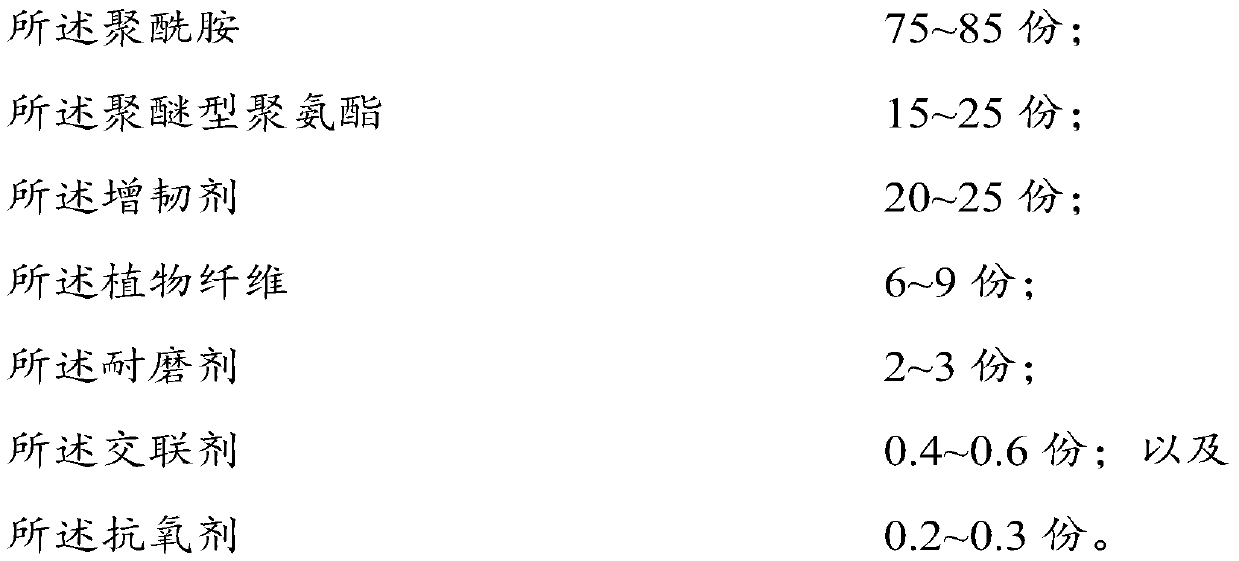

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the wear-resistant material provided in the embodiment of the present application is to mix all the raw materials evenly and then use a screw extruder to extrude and granulate. The operation is simple, the process is convenient, and it is suitable for large-scale production and preparation. When extruding and granulating with screw extruder, the temperature of extruding and granulating is selected as 170-200°C, and the screw speed is 250-270r / min during extruding and granulating, which can ensure sufficient melting of each raw material and prepare stable performance. wear-resistant material particles.

[0051] In some optional embodiments, the extrusion granulation temperature may be 170°C, 175°C, 180°C, 185°C, 190°C, 195°C, 200°C. Optionally, the rotational speed of the screw during extrusion granulation can be 250r / min, 255r / min, 260r / min, 265r / min, 270r / min.

[0052] In the third aspect, the embodiment of the present application provides a ...

Embodiment 1

[0055] This embodiment provides a wear-resistant material, which is prepared by the following method:

[0056] Weigh respectively 80Kg polyamide 1212, 20Kg polyether polyurethane, 20Kg polyolefin elastomer unsaturated carboxylic acid graft copolymer, 6Kg chopped abaca fiber, 3Kg super-zero carbon dioxide intercalation coupling treated hydrotalcite two Molybdenum sulfide nanocomposite, 0.6Kg glycidyl methacrylate and 0.3Kg tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester are used as raw materials, and the raw materials are put into the mixing Stir in the machine for 2 minutes to mix evenly, and then put the mixed materials into the twin-screw extruder.

[0057] The raw materials are extruded and granulated by twin-screw extruder, followed by cooling, pelletizing, drying and packaging. The temperature during extrusion granulation is 200°C, and the temperature of each section of the screw extruder from the feed port to the twin-screw extrusion die...

Embodiment 2

[0059] This embodiment provides a wear-resistant material, which is prepared by the following method:

[0060] Weigh respectively 70Kg polyamide 1212, 10Kg polyether polyurethane, 20Kg polyolefin elastomer unsaturated carboxylic acid graft copolymer, 5Kg chopped abaca fiber, 2Kg super-zero carbon dioxide intercalation coupling treated hydrotalcite two Molybdenum sulfide nanocomposite, 0.2Kg glycidyl methacrylate and 0.1Kg tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester are used as raw materials, and the raw materials are put into the mixing Stir in the machine for 2 minutes, and then put the uniformly mixed material into the twin-screw extruder.

[0061] The raw materials are extruded and granulated by twin-screw extruder, followed by cooling, pelletizing, drying and packaging. The temperature during extrusion granulation is 200°C, and the temperature of each section of the screw extruder from the feeding port to the twin-screw extrusion die i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com