Main-pipe-type on-line pulp-concentration sampling measurement device

A technology for pulp concentration and measuring device, which is applied to measuring devices, sampling devices, instruments, etc., can solve problems such as affecting the utilization rate of main process equipment and production raw materials, affecting the service life of the concentration meter sensor 4, and measuring deviation of the concentration meter sensor 4. , to achieve the effect of maintaining measurement accuracy and long-term stability, not easy to swirl, and simple in composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

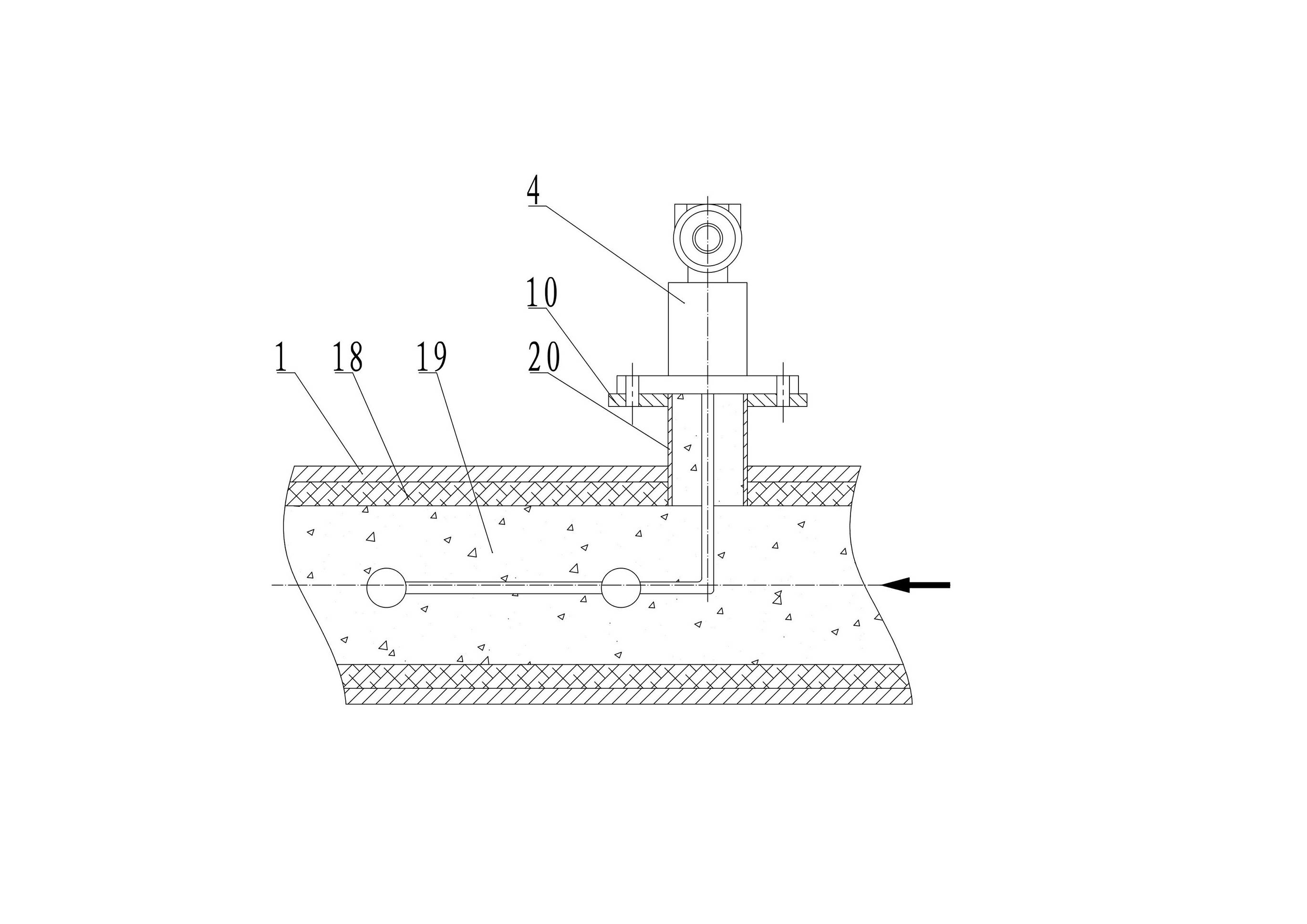

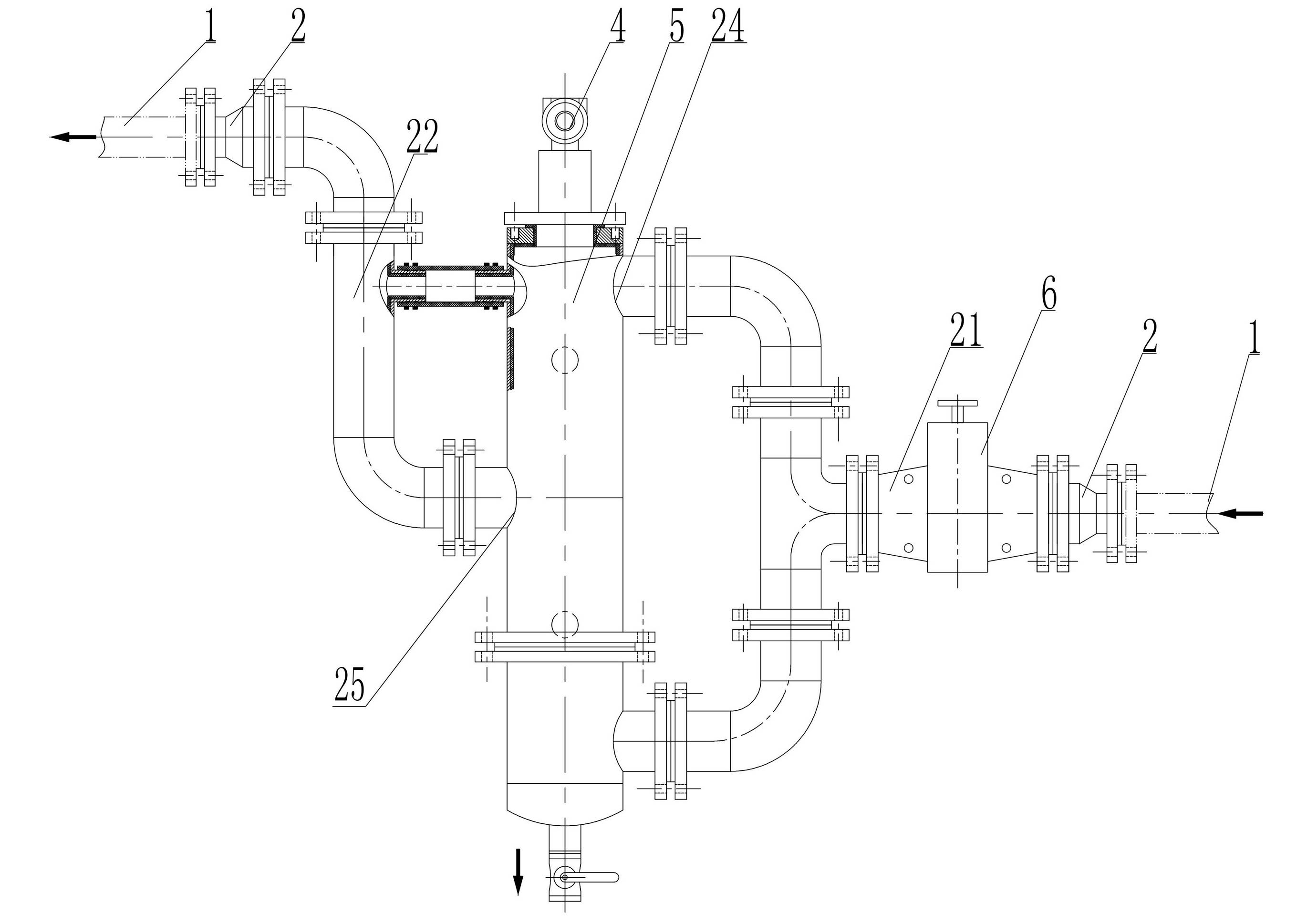

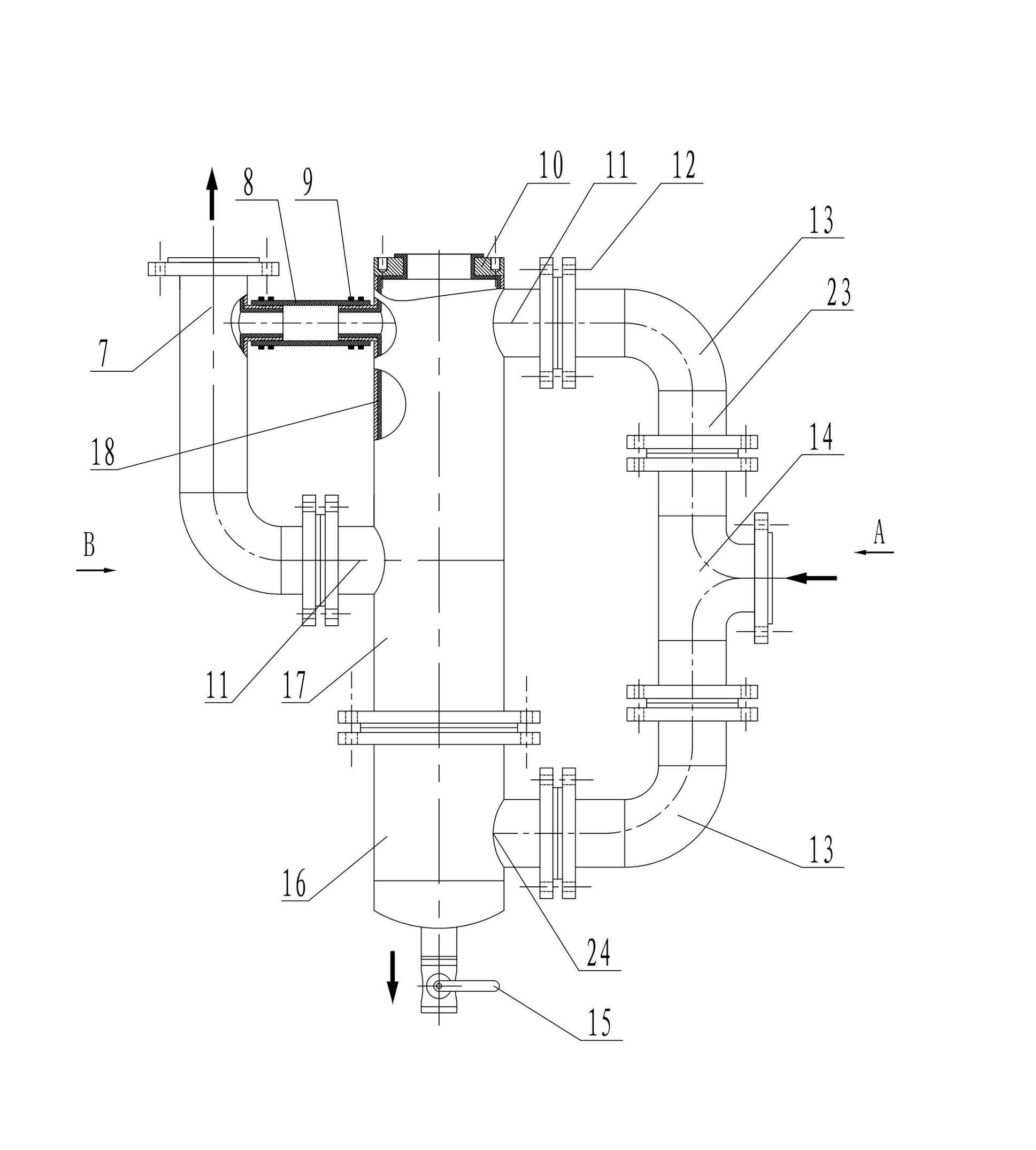

[0031] Such as Figure 2 to Figure 5 As shown, the main pipe type slurry concentration on-line sampling and measuring device of the present invention is suitable for on-line sampling and measurement of slurry concentration in small-diameter process pipelines. It includes a sampling assembly installed between two sections of process pipelines 1, a sampling tank 5 and a sampling assembly, and becomes an integral part of the process pipeline 1. A sampling inlet 24 is respectively provided on the upper and lower parts of one side of the sampling tank 5. The sample port 24 is connected with the sampling assembly, and a sample outlet 25 is opened on the other side of the sampling tank 5, and the sample outlet 25 is located between the two sample inlets 24, and the sample outlet 25 is connected with the sampling assembly. The top of 5 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com