Method for determining low-temperature working stress limit of aircraft anti-skid braking control box

A work stress, anti-skid braking technology, applied in measuring devices, instruments, measuring electricity and other directions, can solve problems such as unrealistic data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

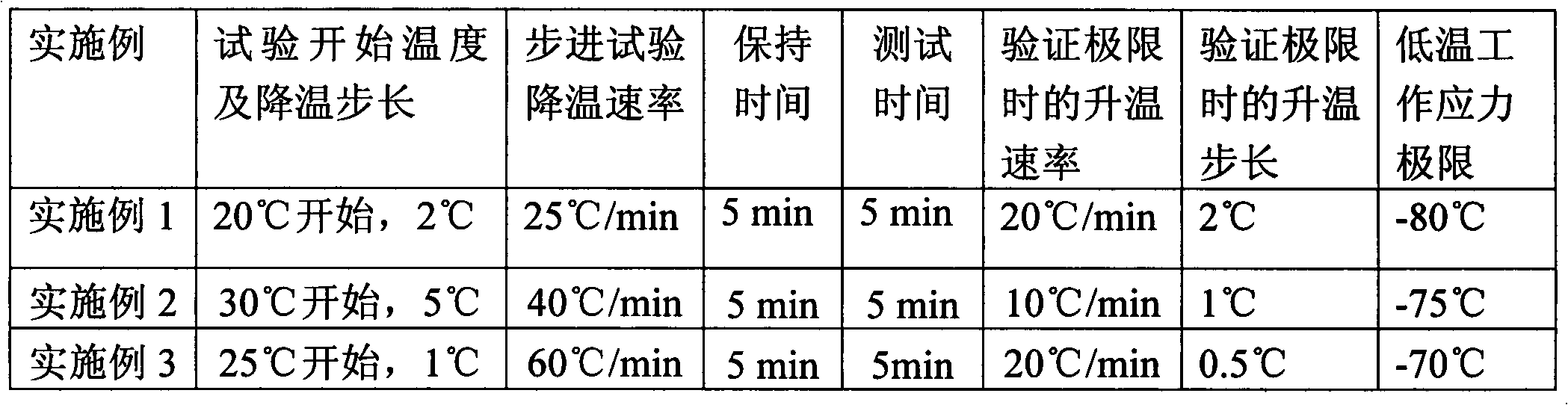

Embodiment 1

[0027] This embodiment is a test for determining the low-temperature working stress limit of the first type of control box, and the test samples are 2 sets of control boxes. The design of the test sample has been improved for the low temperature problem in the development test.

[0028] The test of this embodiment uses a reliability enhancement test box model UHS1200, a digital multimeter, a signal source and an oscilloscope.

[0029] The concrete process of this embodiment is:

[0030] Step 1, determine the test parameters. The test parameters include test temperature starting point, cooling step size and cooling rate. The cooling step is not greater than 5°C, and the smaller the more accurate, the starting point of the test temperature in this embodiment is 20°C, the cooling step is 2°C, and the cooling rate is 25°C / min.

[0031] Step 2, heating the test sample. Install the 2 sets of test samples on the moving coil in the strengthening test box with fixtures. Heat the t...

Embodiment 2

[0036] This embodiment is a test for determining the low-temperature working stress limit of the second type of control box, and the test sample is a set of control boxes. The design of the test sample has been improved for the low temperature problem in the development test.

[0037] The test of this embodiment uses a reliability enhancement test box model UHS1200, a digital multimeter, a signal source and an oscilloscope.

[0038] The concrete process of this embodiment is:

[0039] Step 1, determine the test parameters. The test parameters include test temperature starting point, cooling step size and cooling rate. The cooling step is not greater than 5°C, and the smaller the more accurate, the starting point of the test temperature in this embodiment is 30°C, the cooling step is 5°C, and the cooling rate is 40°C / min.

[0040] Step 2, heating the test sample. One set of test samples is installed on the moving coil in the strengthening test box with the fixture. Heat th...

Embodiment 3

[0045] This embodiment is a test for determining the low-temperature working stress limit of the third type of control box, and the test sample is a set of control boxes. The design of the test sample has been improved for the low temperature problem in the development test.

[0046] The test of this embodiment uses a reliability enhancement test box model UHS1200, a digital multimeter, a signal source and an oscilloscope.

[0047] The concrete process of this embodiment is:

[0048] Step 1, determine the test parameters. The test parameters include test temperature starting point, cooling step size and cooling rate. The cooling step is not greater than 5°C, and the smaller the more accurate, the starting point of the test temperature in this embodiment is 25°C, the cooling step is 1°C, and the cooling rate is 60°C / min.

[0049] Step 2, heating the test sample. One set of test samples is installed on the moving coil in the strengthening test box with the fixture. Heat the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com