Magnetoelectronic angle sensor, in particular a reluctance resolver

An angle sensor, electromagnetic technology, applied in the direction of using electric/magnetic devices to transmit sensing components, converting sensor output, using electromagnetic means, etc., can solve the problems of measurement accuracy influence, tolerance, complex assembly methods, etc., to achieve the effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

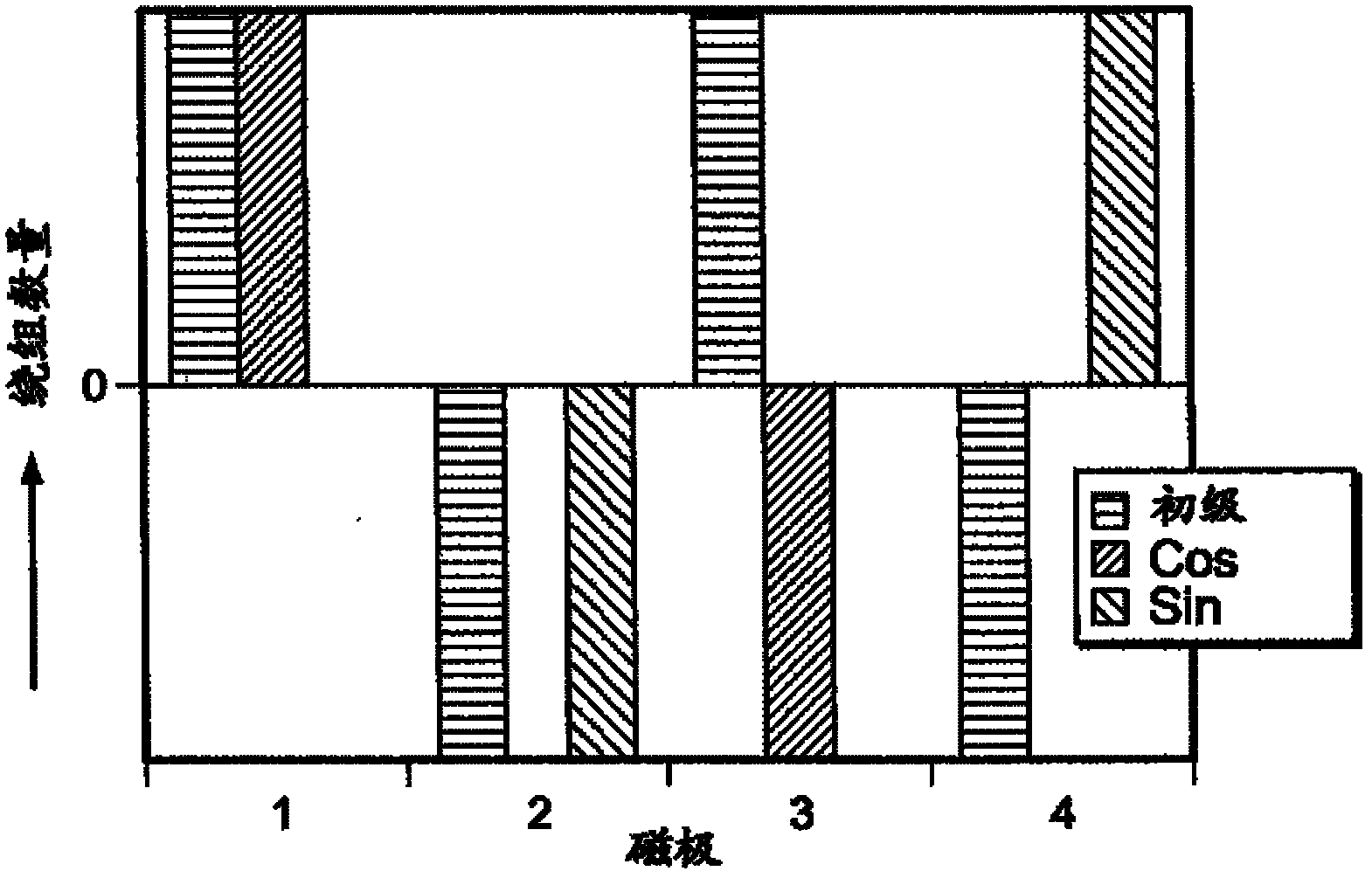

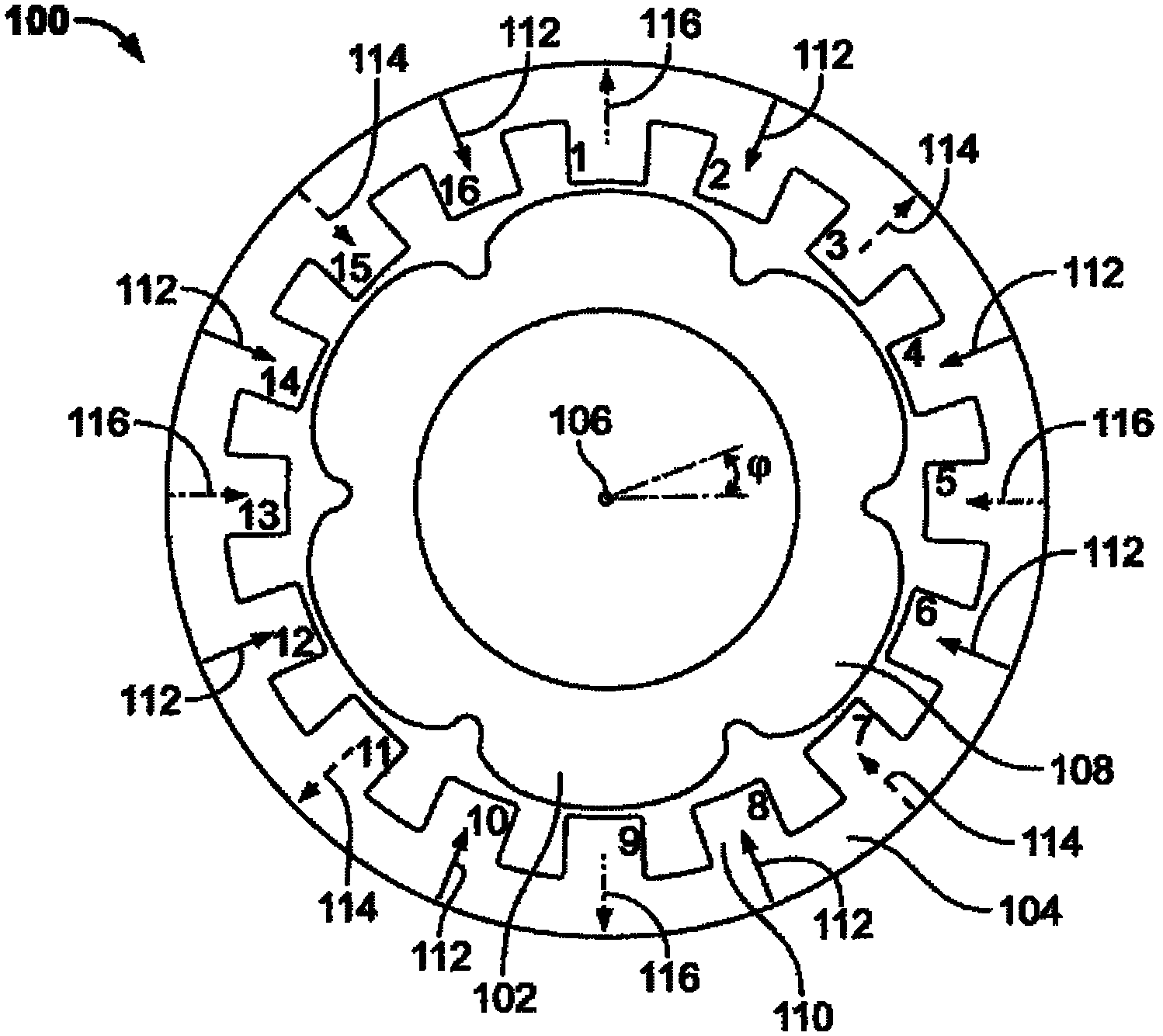

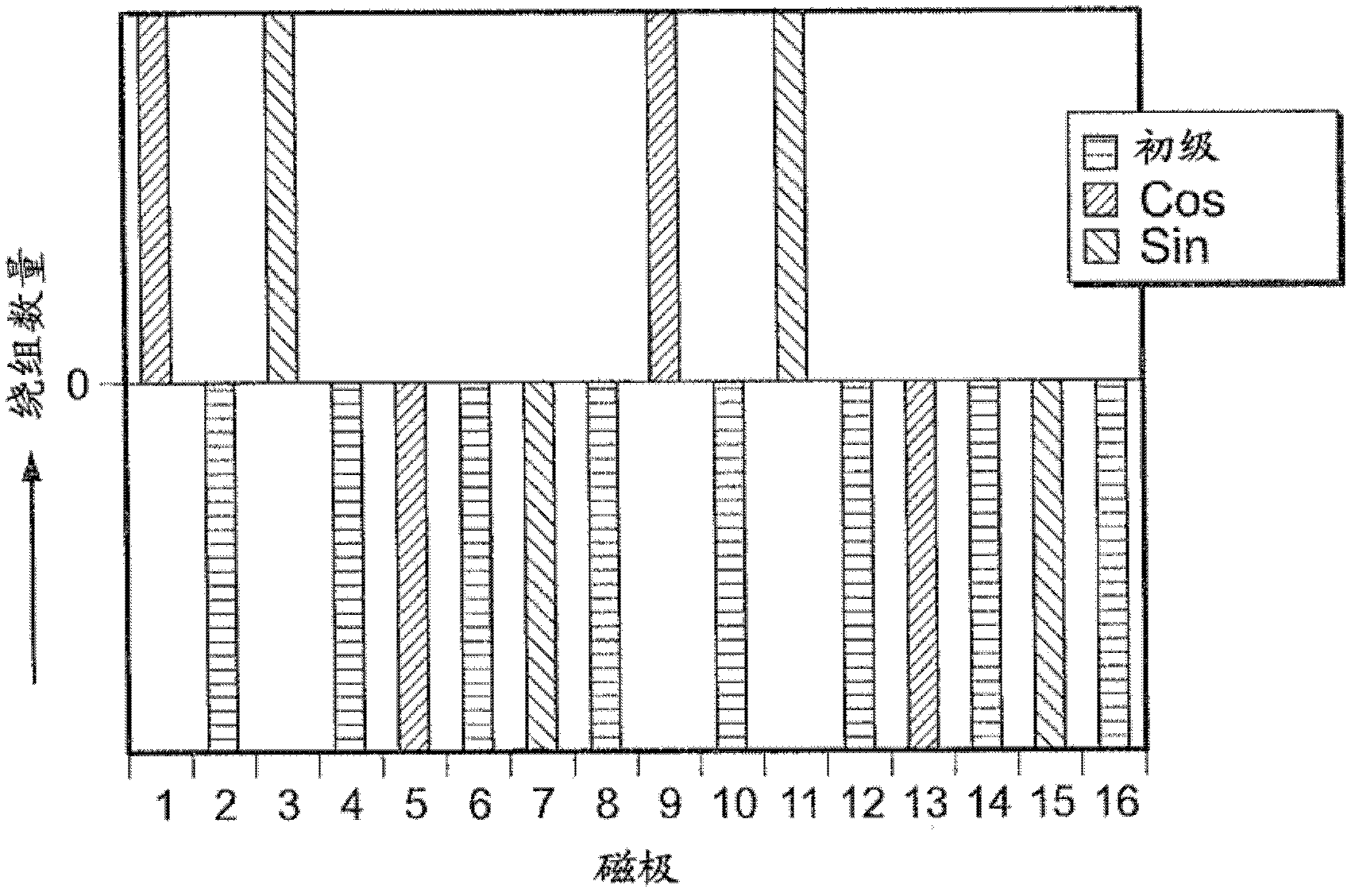

[0039] figure 2 is a schematic cross-sectional view through the six-speed resolver 100 according to the first embodiment of the present invention. In this case, a soft magnetic rotor 102 is mounted within a stator 104 to be rotatable about a rotational axis 106 . The rotor in the embodiment shown in this figure has six lugs 108 which, during rotation about the axis 106 , create a variable air gap between the teeth 110 of the stator 104 and the rotor 102 . The six-speed resolver configuration as shown in this figure provides a total of sixteen teeth 110, which are figure 2 Numbered sequentially in a clockwise direction. The magnetic flux occurring on the teeth 110 is marked by arrows. According to the invention, the even numbered teeth, which may also be called poles, in this case carry primary windings wound such that their magnetic flux 112 is directed towards the axis of rotation 106 when the exciting primary current is positive. The direction is directed inward. The magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com