Integrated mould box capable of forming and delivering external preparation

A technology for external preparations and mold boxes, which is applied in the direction of making medicines into special physical or taking forms of devices, medicine equipment, other medical equipment, etc. Internal and other problems, to achieve the effect of not easy to contaminate, accurate medication location, good medication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

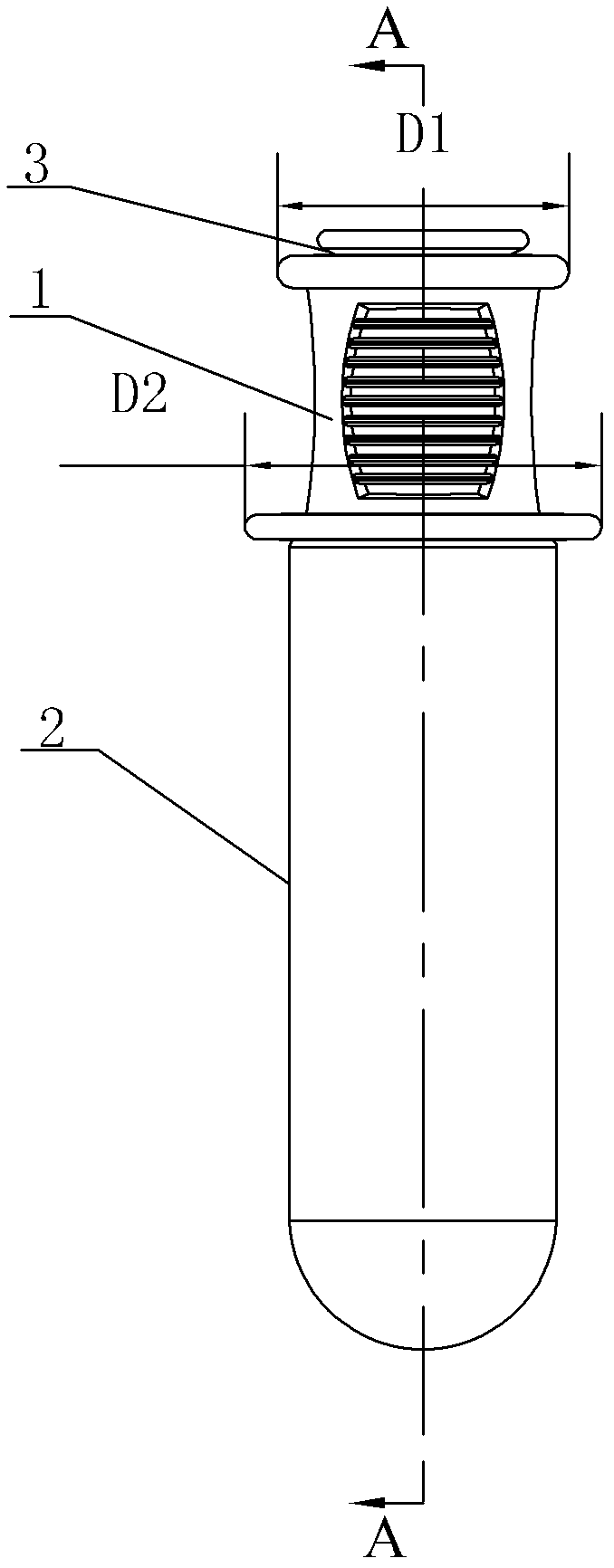

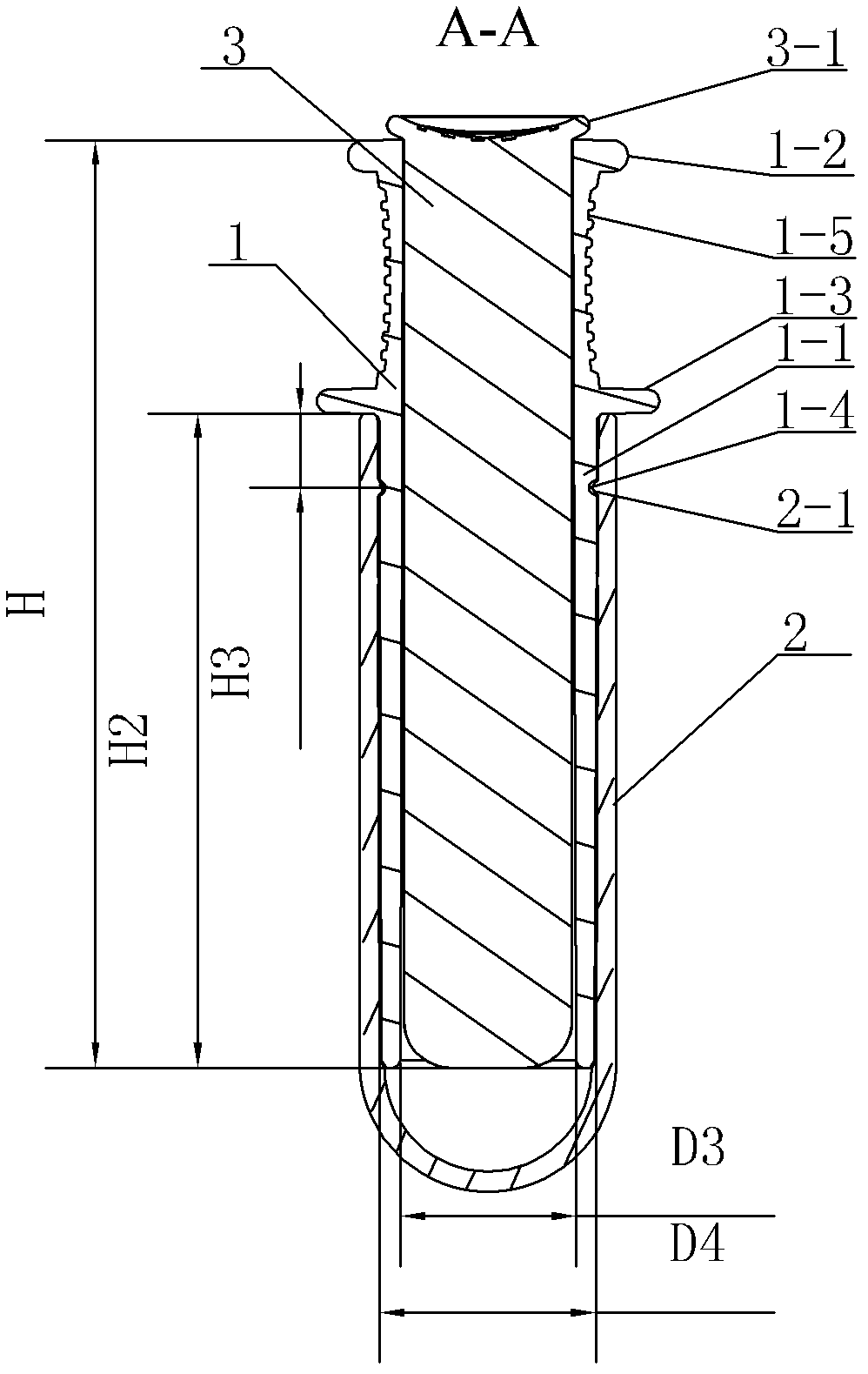

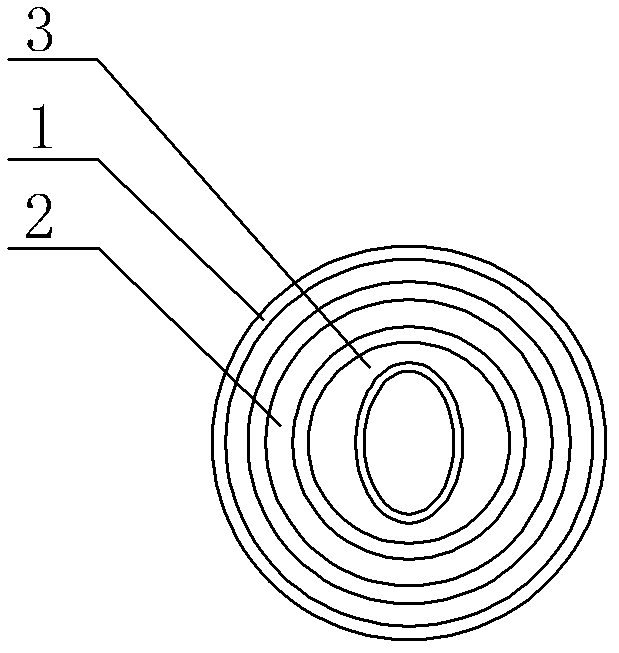

[0007] Specific implementation mode one: combine Figure 1 to Figure 5 This embodiment is described. An external preparation molding and propulsion integrated mold box of this embodiment includes a middle mold 1, a lower mold 2 and a push rod 3. The middle mold 1 is composed of a mold sleeve 1-1, a first retaining ring 1-2 and the second retaining ring 1-3, the lower end of the lower die 2 is a closed end, the upper end of the lower die 2 is an open end, the lower die 2 has a mold cavity, the first retaining ring 1-2 and The second retaining ring 1-3 is arranged on the outer side wall of the mold case 1-1 from top to bottom, the first retaining ring 1-2 is located on the upper end surface of the die case 1-1, the first retaining ring 1-2, The second retaining ring 1-3 and the mold cover 1-1 are coaxially arranged and made into one body, and an annular groove 1-4 is arranged below the second retaining ring 1-3 on the outer wall of the die cover 1-1. The upper end of the inner ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 2 To illustrate this embodiment, there are a plurality of anti-slip grooves 1-5 on the outer wall of the mold case 1-1 in this embodiment between the first retaining ring 1-2 and the second retaining ring 1-3. Such setting is convenient for patients to operate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 To describe this embodiment, the cavity shape of the mold case 1-1 described in this embodiment is cylindrical. Such setting meets the design requirements and is convenient to use. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com