Thermal deformation technique of flange with abnormal section

A special-shaped cross-section and thermal deformation technology, which is applied in metal rolling and other directions, can solve problems such as the collapse of the upper end of the billet, consume energy, reduce the strength of the ring, and achieve the effects of saving raw materials, reducing energy waste, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

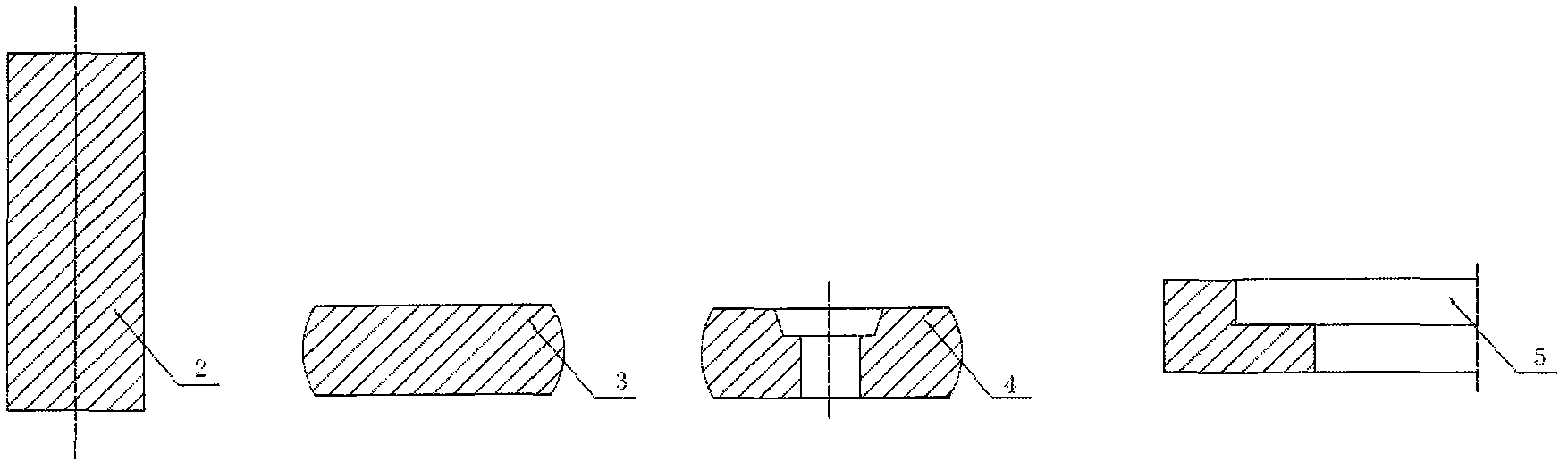

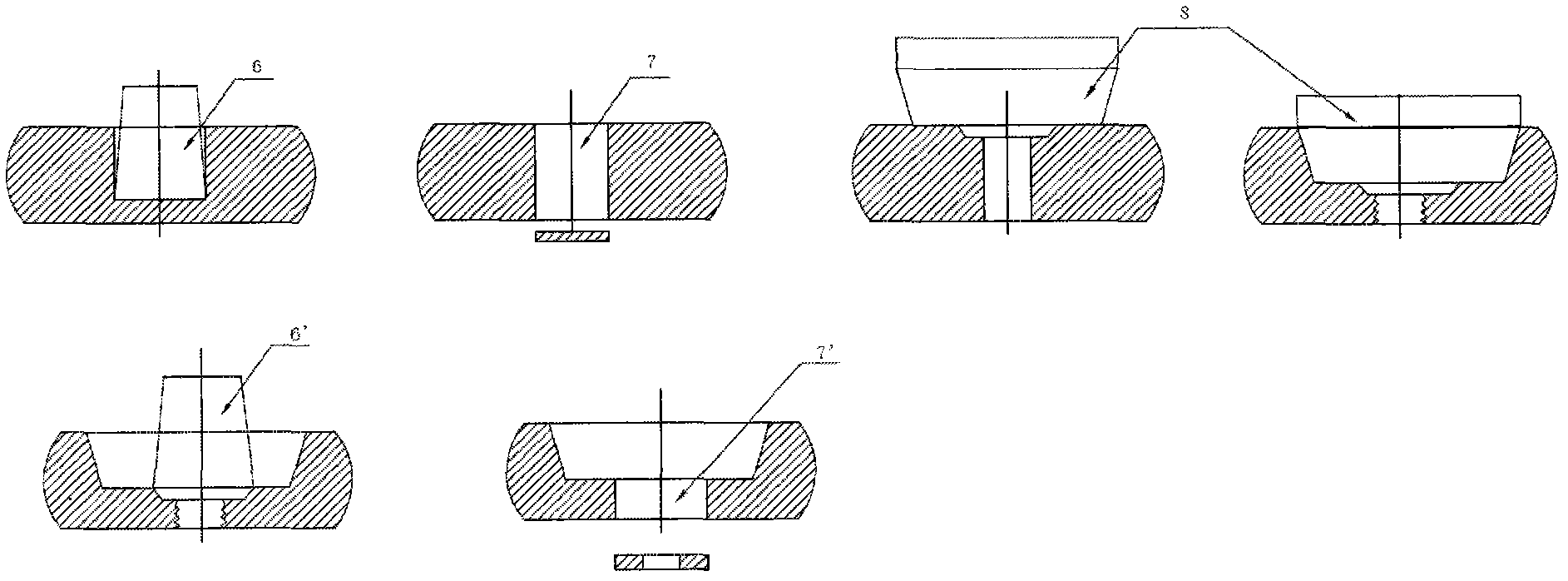

[0036] For example, the weight of the tower-top wind tower flange with an L-shaped rolling cross-section is about 2-10 tons, and the outer diameter is 4-7m. If the cross-sectional size changes slightly, the billet weight will vary greatly.

[0037] The design principles of the L-shaped tower top-shaped wind tower flange are: simple operation, practicality, and installation; regular billet shape, accurate positioning, good ring billet formation, simple and convenient mold replacement.

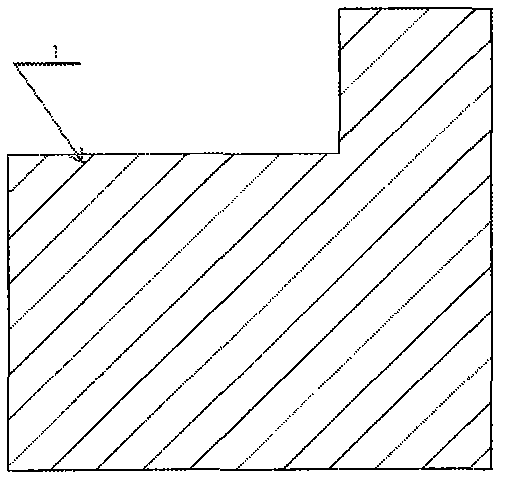

[0038] The thermal deformation process includes: heating the steel ingot and upsetting the steel billet with a 4000 upsetting oil press, and then punching a small through hole in the center of the billet with a solid punch with a diameter of 300mm, and then pressing the small hole into a large one with a positioning die. Step hole, then use a solid punch with a diameter of 400mm to punch out a large through hole in the center of the billet, and leave a section of stepped hole with a positioning d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com