Device and method for assisting in injecting grinding liquid in grinding wheel airflow field

An airflow field and grinding fluid technology, applied in the field of grinding fluid supply, can solve the problems of complex structure, high cost, and easy vibration of the grinding wheel in the liquid supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

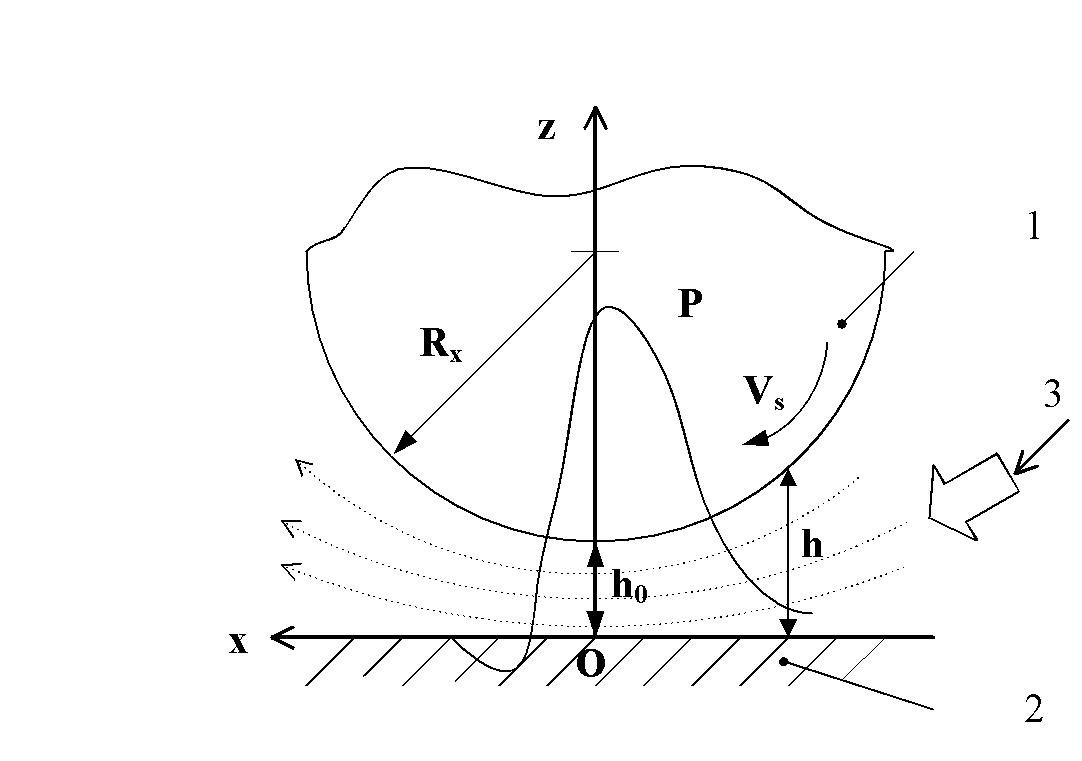

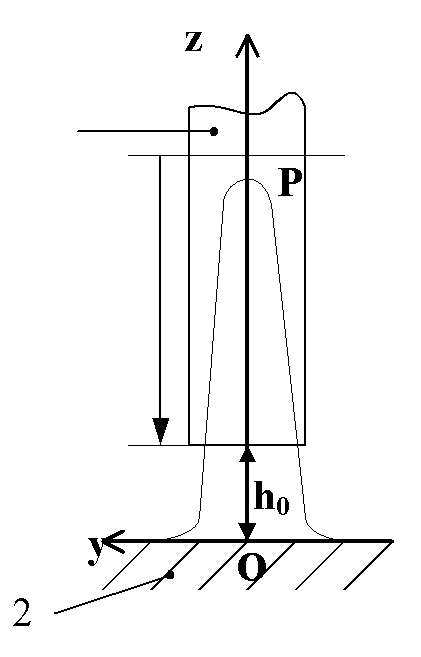

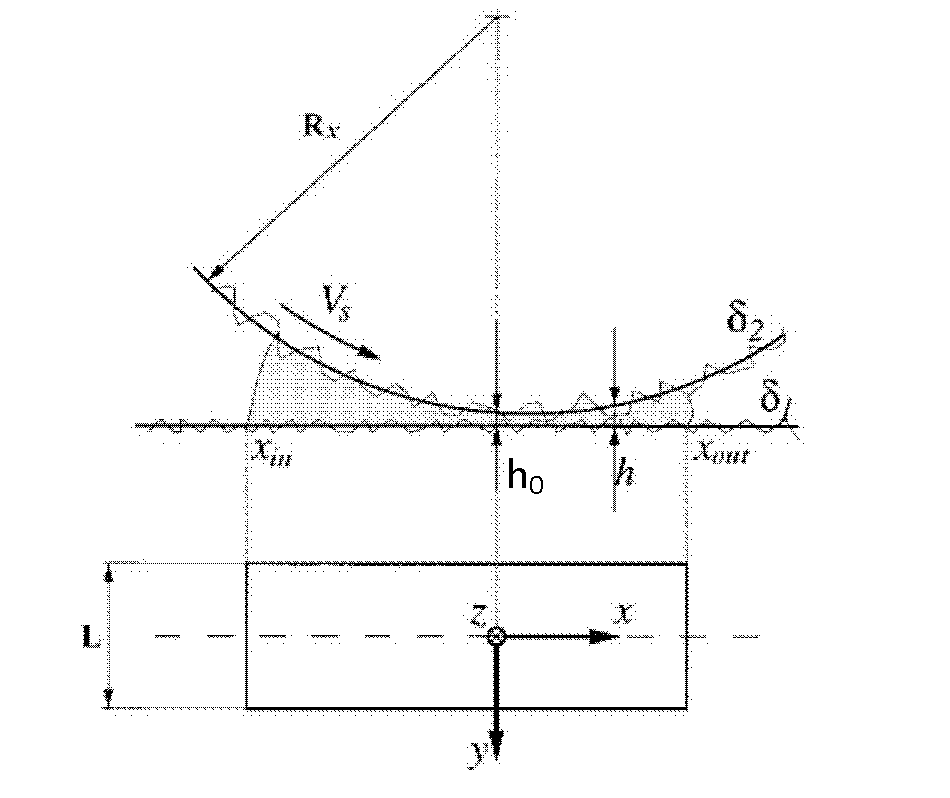

[0065] Figure 1a Among them, a method for assisting the injection of grinding fluid by the airflow field of the grinding wheel of the present invention, the position of the nozzle for supplying the grinding fluid is set above the return flow of the airflow field in the wedge-shaped grinding area, and the position is tangent to the circumference of the grinding wheel; The speed of the grinding fluid is equal to the peripheral speed of the grinding wheel. With the help of the speed of the grinding wheel and the energy obtained from the rapid increase of the pressure and velocity of the airflow field in the wedge grinding area, the auxiliary grinding fluid is injected into the cutting area.

[0066] The exit position of the nozzle is 0.5-1mm away from the surface of the grinding wheel 1; the distance between the exit of the nozzle and the workpiece is 60-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com