Longitudinal and transverse conversion collector for strip cigarette

A technology for collecting machines and cigarettes, applied in packaging and other directions, can solve the problems of large equipment volume, low production efficiency, and affecting the appearance quality of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

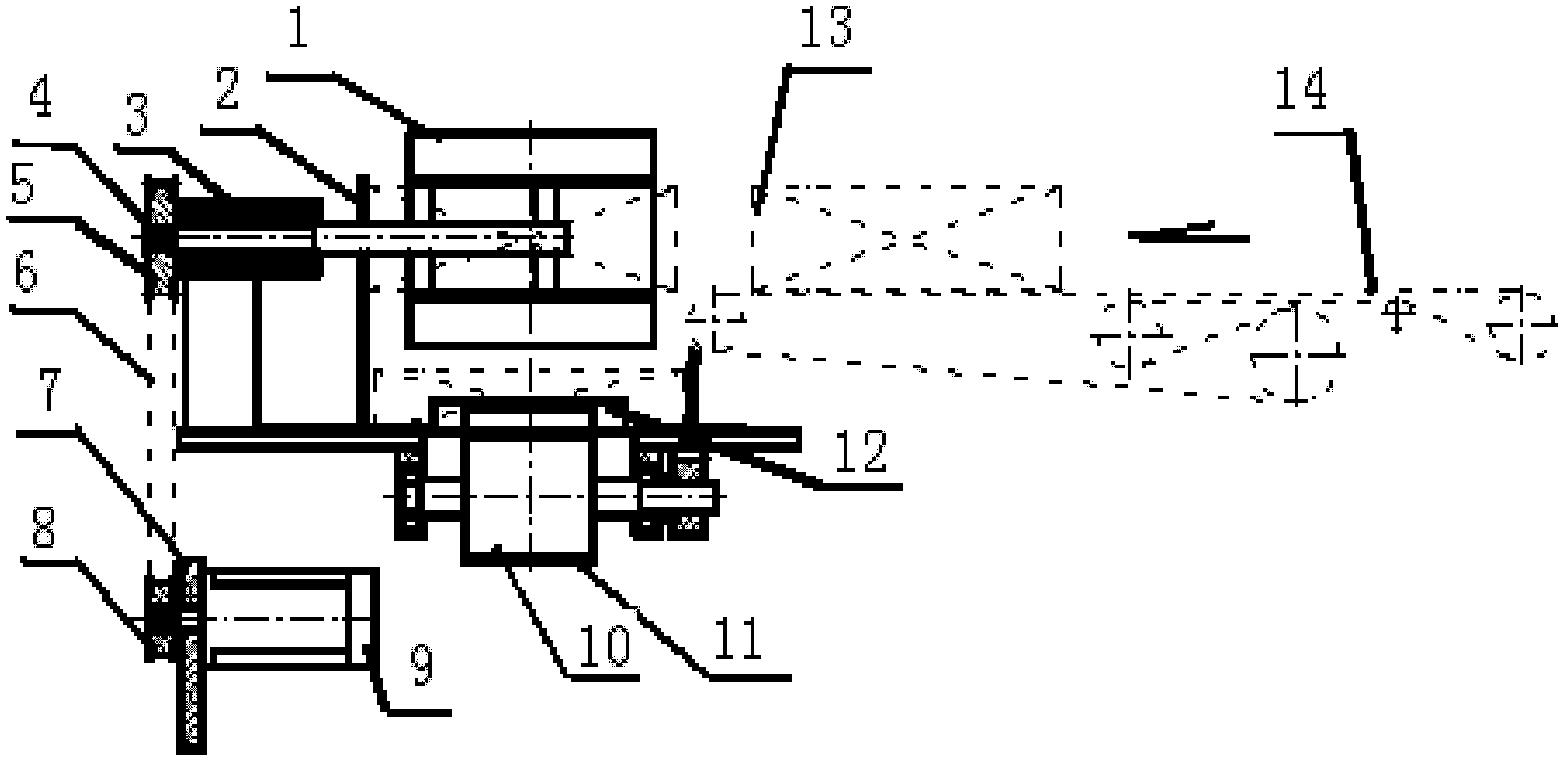

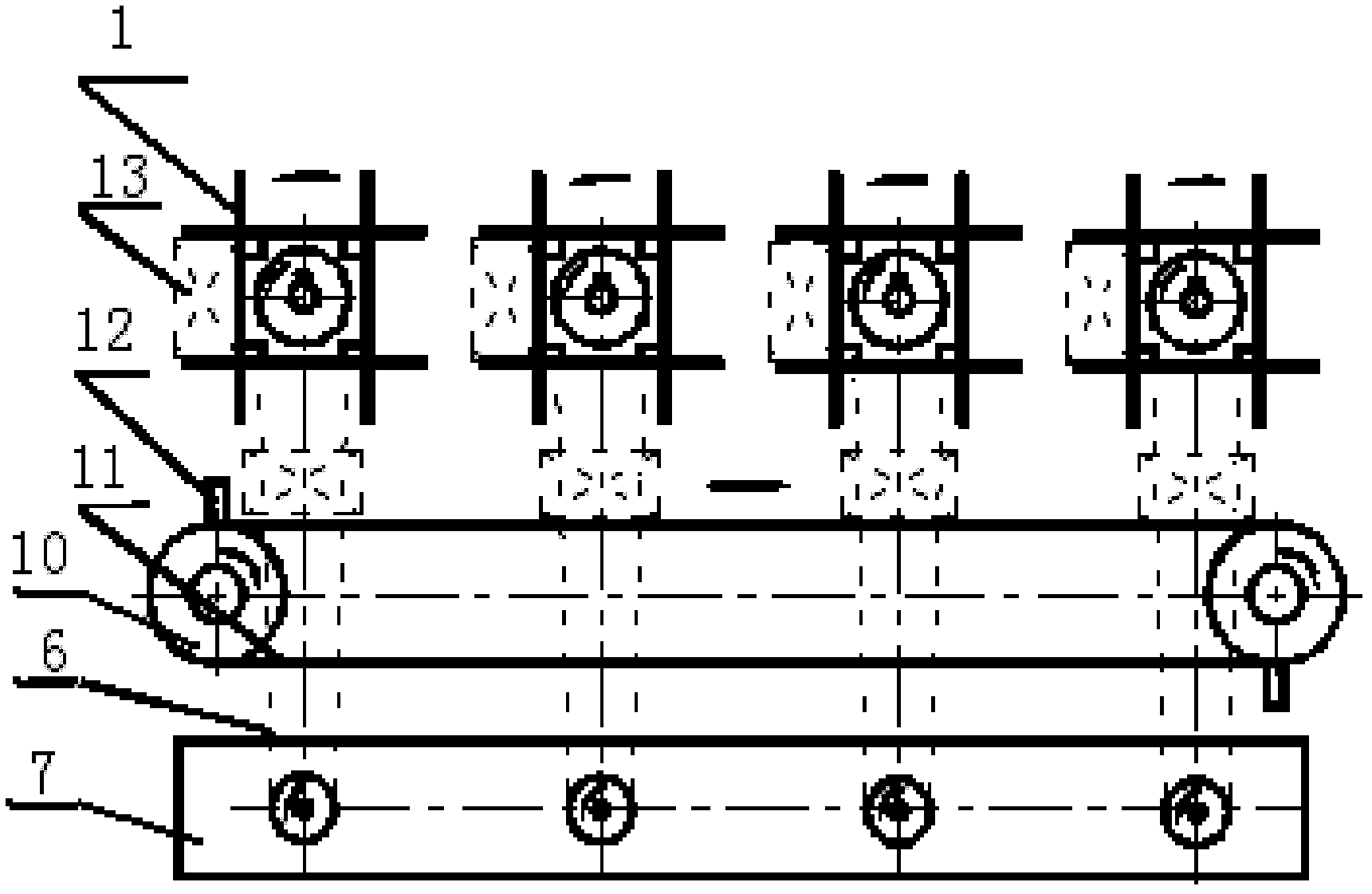

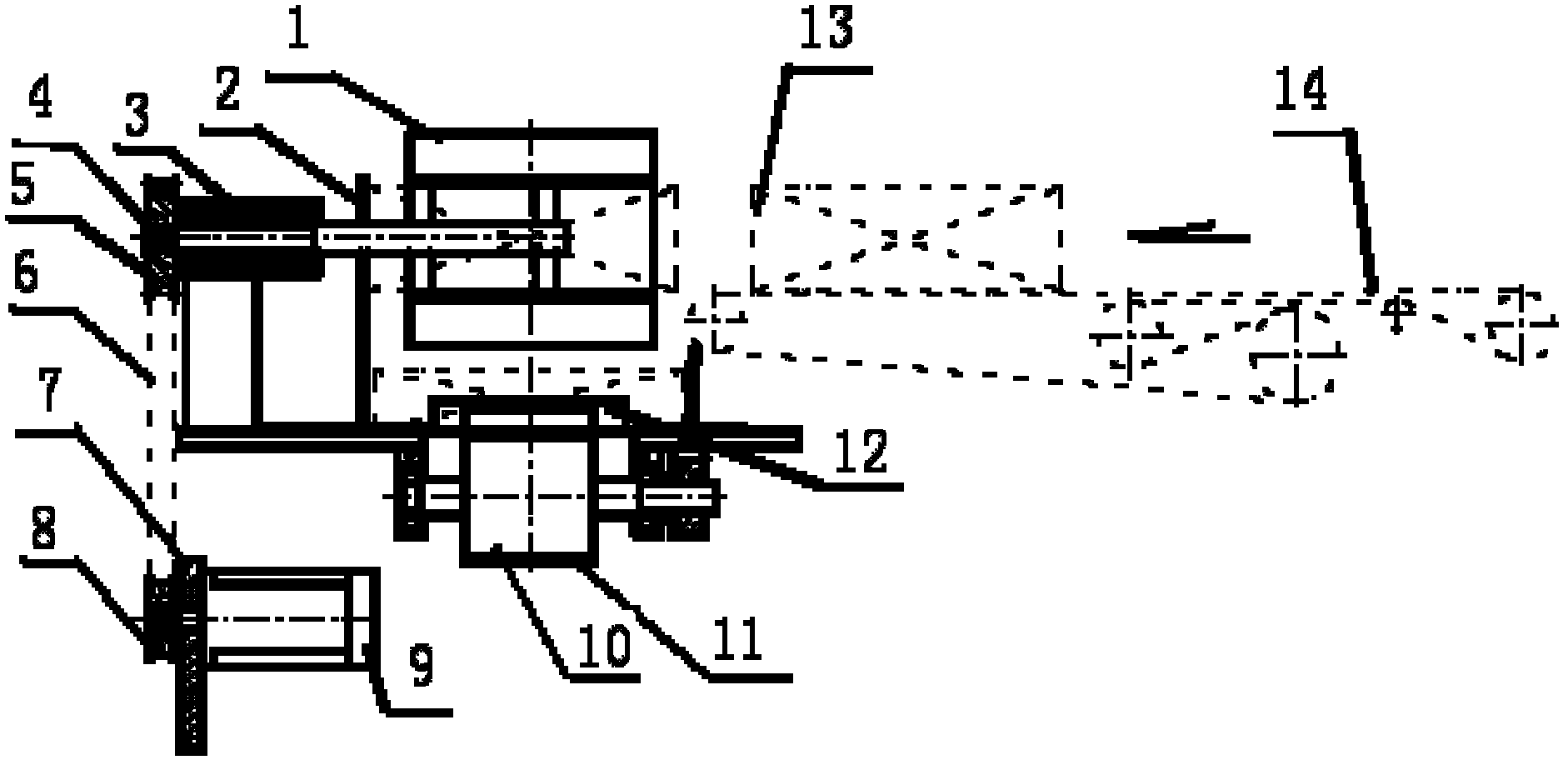

[0011] Further illustrate structure of the present invention in conjunction with accompanying drawing:

[0012] Such as Figure 1-2 As shown, the vertical and horizontal turning and collecting machine for cigarettes is the vertical and horizontal turning and collecting machine for cigarettes of the present invention. Electric mechanism, pulley, scraper conveyor belt, scraper and other components; Among them: the grooved wheel 1 is fixed on the transmission shaft 4 with a flat key and locking bolt, the transmission shaft 4 is installed on the bearing seat 3 through the bearing, and the bearing seat 3 is fixed on the frame, the slave pulley 5 is fixed on the transmission shaft 4 with a flat key and a locking bolt, and connected with the main pulley 8 through the transmission belt 6, and the main pulley 8 is fixed on the power actuator with a flat key and a locking bolt On the output shaft of mechanism 9, power actuator 9 is installed on the frame. The power actuator 9 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com