Method for preparing rosin-based regular polymers

A polymer, rosin-based technology, applied in the field of preparation of rosin-based regular polymers, can solve the problem of no rosin-like substance polymerization and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

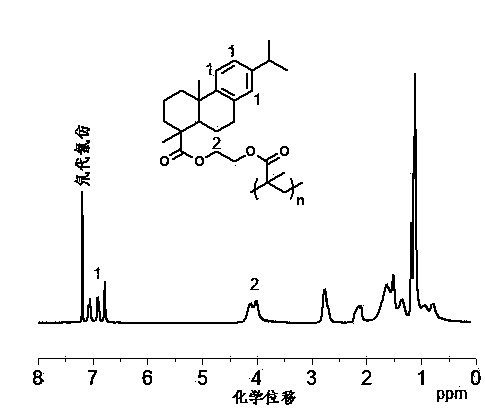

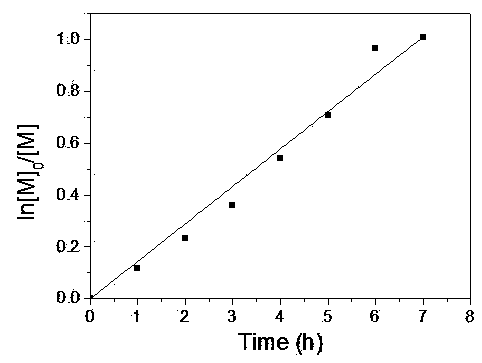

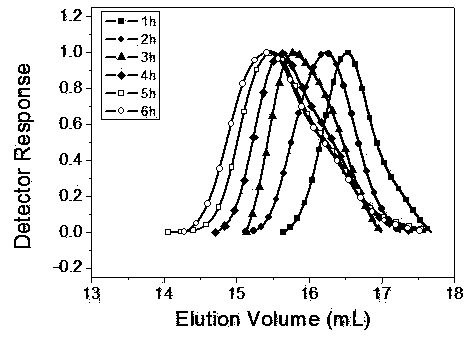

[0035] DAME monomer 10g, RAFT reagent (CDB, cumyl dithiobenzoate) 66mg and AIBN (azobisisobutyronitrile) 4.0mg, molar ratio ([DAE]: [CDB]: [AIBN] =[100]:[1]:[0.1]) was added to 20ml of toluene, the solution was transferred to an eggplant-shaped reaction flask, and nitrogen was bubbled to remove oxygen for 15 minutes. After reacting at 70°C for 24 hours, the monomer conversion rate was 95%. Polymer molecular weight: M n (GPC): 25600 g / mol, PDI=1.22. Mn (NMR): 37800 g / mol.

Embodiment 2

[0037] DAME monomer 10g, RAFT reagent (CDB, cumyl dithiobenzoate) 66mg and AIBN (azobisisobutyronitrile) 4.0mg, molar ratio ([DAME]: [CDB]: [AIBN] = [100]: [1]: [0.1]) Add 20ml of toluene, transfer the mixture to an eggplant-shaped reaction flask, and bubbling with nitrogen to remove oxygen for 15 minutes. After reacting at 100°C for 12 hours, the monomer conversion rate was 35%. Polymer molecular weight: M n (GPC): 10,600g / mol, PDI=1.29.M n (NMR): 12900 g / mol.

[0038] After 24 hours of reaction, the monomer conversion rate was 45%. Polymer molecular weight: M n (GPC): 15,300g / mol, PDI=1.67.M n (NMR): 17900 g / mol.

[0039] It can be seen from the reaction that using toluene as the solvent and reacting at 100°C, the reaction is controlled when the conversion rate is lower than 35%. When the conversion rate continues to increase, the PDI increases and the structure becomes Can not control.

Embodiment 3

[0041] DAME monomer 10g, RAFT reagent (CDB, cumyl dithiobenzoate) 66mg and AIBN (azobisisobutyronitrile) 4.0mg, molar ratio ([DAME]: [CDB]: [AIBN] =[100]:[1]:[0.1]) was added to 20ml of tetrahydrofuran, the solution was transferred to an eggplant-shaped reaction flask, and nitrogen was bubbled to remove oxygen for 15 minutes. After reacting at 80°C for 12 hours, the polymer was precipitated in methanol, and then filtered and dried to obtain rosin-based polymers with different molecular weights. The monomer conversion rate was 42%. Polymer molecular weight: M n (GPC): 8600g / mol, PDI=1.46.M n (NMR): 17000g / mol

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com