Castor-oil-based ordered polymer and preparation method thereof

A castor oil-based, polymer technology, applied in the field of synthesis of castor oil-based three-wall polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation process of the castor oil-based regular three-arm polymer is divided into two steps, the first step is to modify the castor oil into an ATRP initiator with three active polymerization centers, and the second step is to carry out ATRP active polymerization Synthetic sesame oil-based regular polymer;

[0032] In the process of preparing ATRP, the organic solvent used to dissolve castor is dichloromethane, tetrahydrofuran, chloroform, ether, etc.;

[0033] In the process of preparing ATRP, the catalyst used to catalyze the reaction between castor oil and 2-bromoisobutyl acyl is one of N,N-lutidine, triethylamine, pyridine, sodium carbonate, and sodium bicarbonate;

[0034] In the described preparation ATRP initiator process, temperature of reaction is 0~40 ℃;

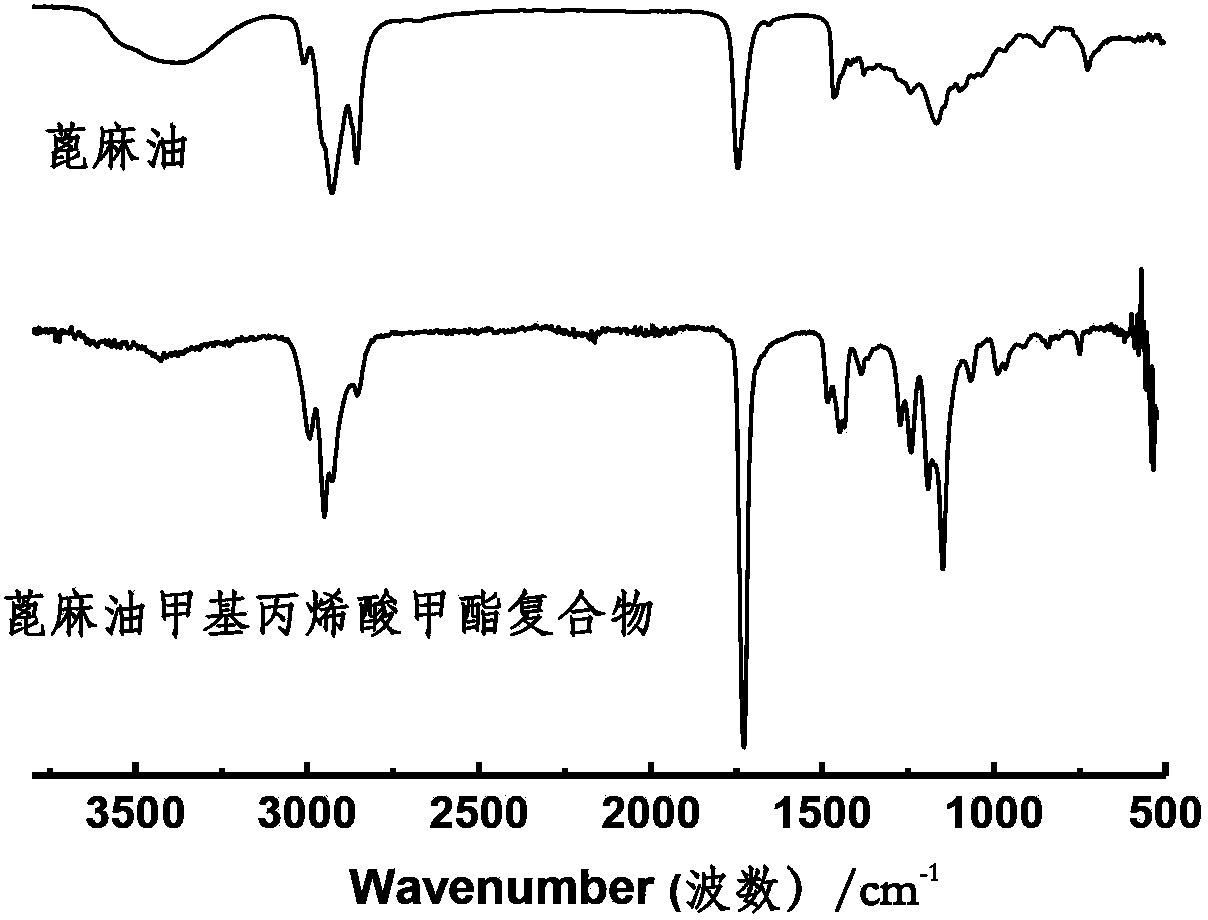

[0035] The monomer described in the preparation ATRP active polymerization reaction is methyl methacrylate, butyl acrylate, butyl methacrylate, acrylate-2-hydroxyethyl ester, methacrylate-2-hydroxye...

Embodiment 1

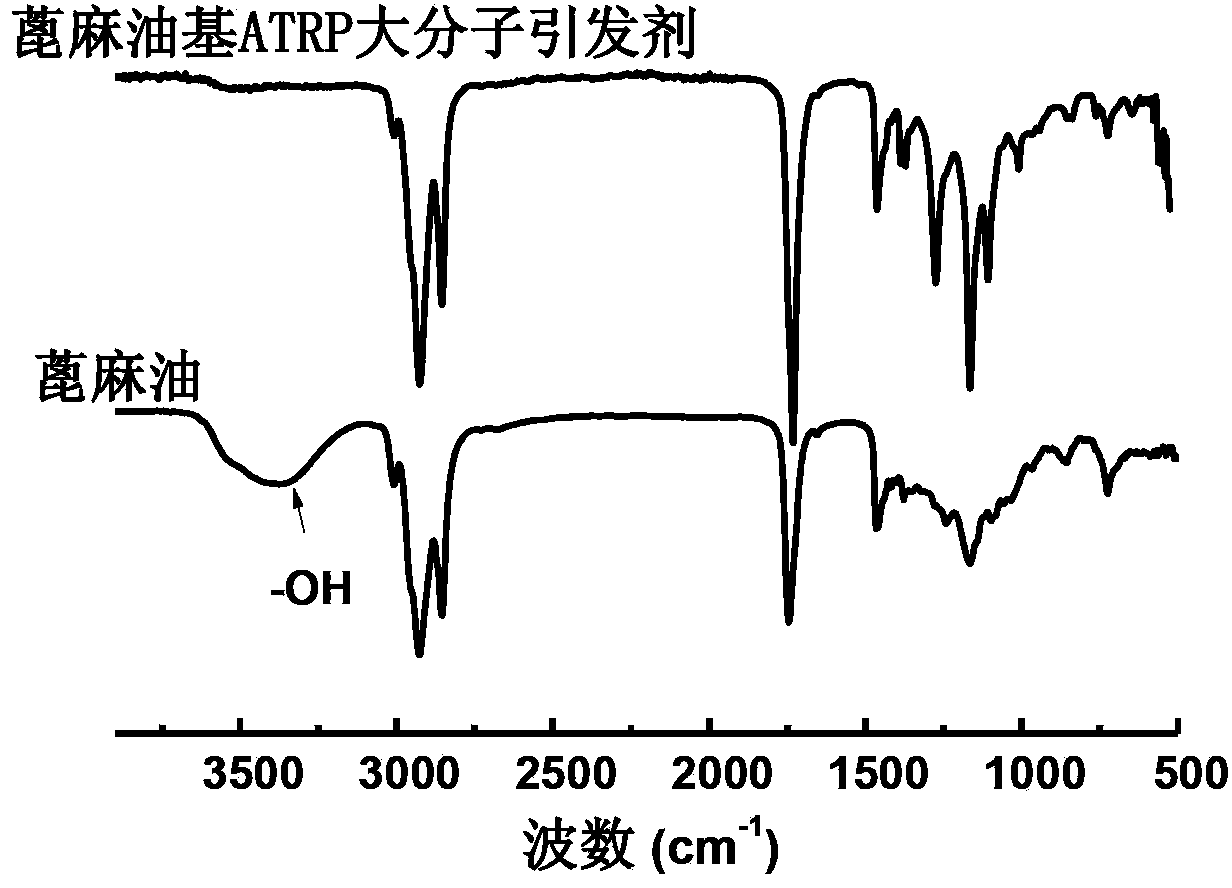

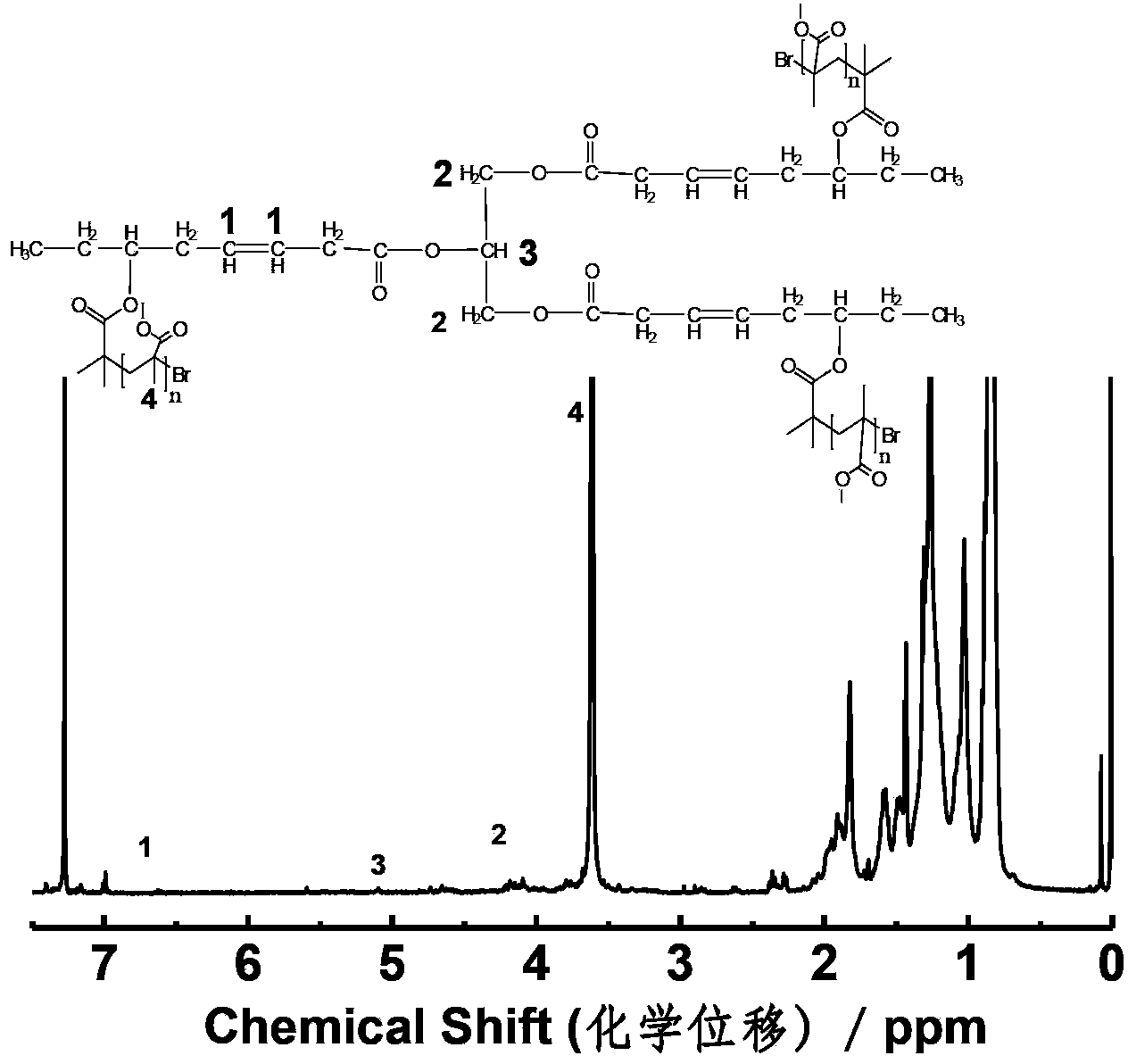

[0048] Synthesis of castor oil-based ATRP polymerization macroinitiator:

[0049] Castor oil 10g, catalyst triethylamine 10.2g are dissolved in tetrahydrofuran, the temperature of solution is set as 5 ℃, after gradually dripping 23g2-bromoisobutyl acid bromide, react at 5 ℃ for 12 hours, filter , remove solvent and dry three steps and obtain castor oil-based ATRP polymerization macroinitiator; Synthetic process functional group changes as follows figure 2 shown.

Embodiment 2

[0051] Synthesis of castor oil-based ATRP polymerization macroinitiator:

[0052] Dissolve castor oil 10g, catalyst N,N-lutidine 12.3g in tetrahydrofuran, set the temperature of the solution to 5°C, gradually drop 23g of 2-bromoisobutyryl bromide, and react at 5°C 5 hours, obtained castor oil-based ATRP polymerization macroinitiator through three steps of filtering, removing solvent and drying; Synthetic process functional group changes and figure 2 Same as shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com