Halogen-free thermosetting resin composition and prepreg and laminated board manufactured by same

A resin composition and thermosetting technology, which is applied in the field of halogen-free thermosetting resin composition, prepreg and laminate, and can solve the problem of poor processability of phenolic curing system, easy moisture absorption of phosphorus-containing epoxy resin, insufficient heat resistance of immersion tin, etc. Problems, achieve the effect of improving toughness and processability, low expansion rate requirements, improving moisture resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

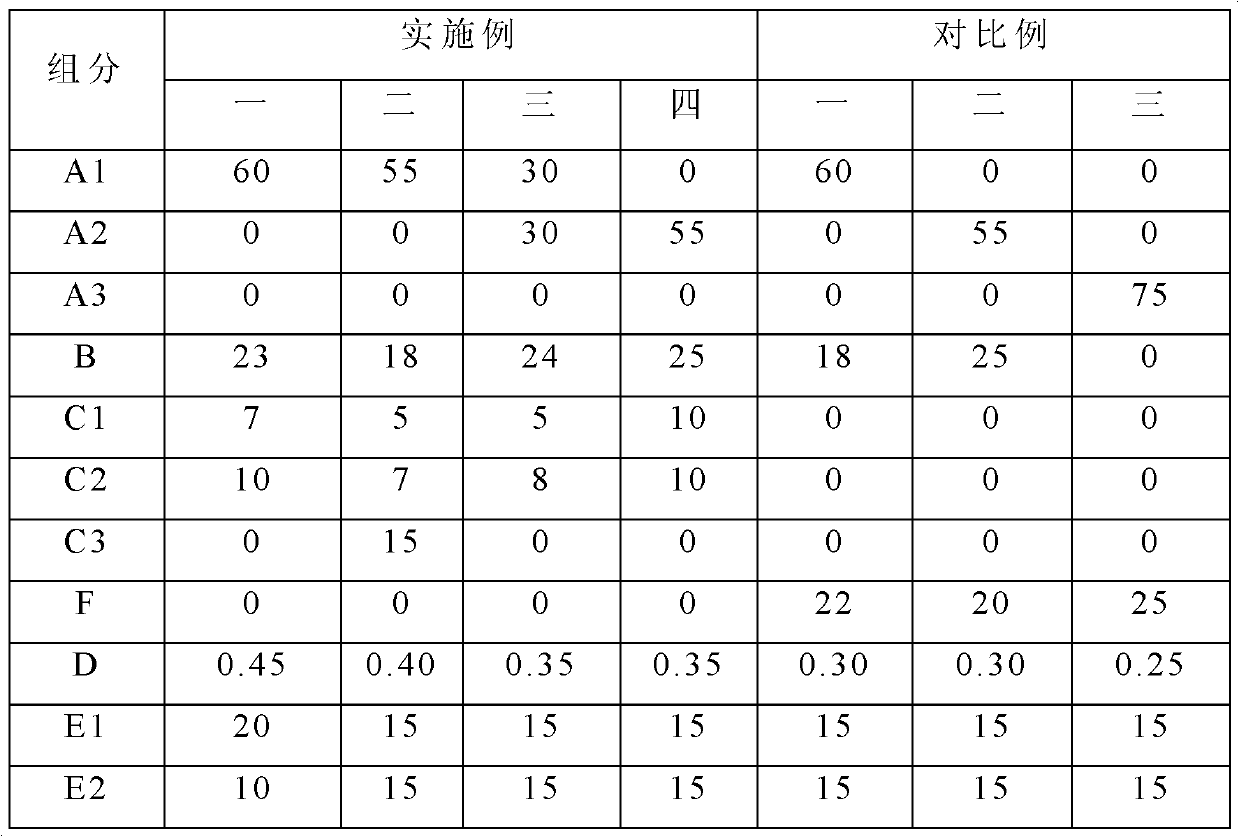

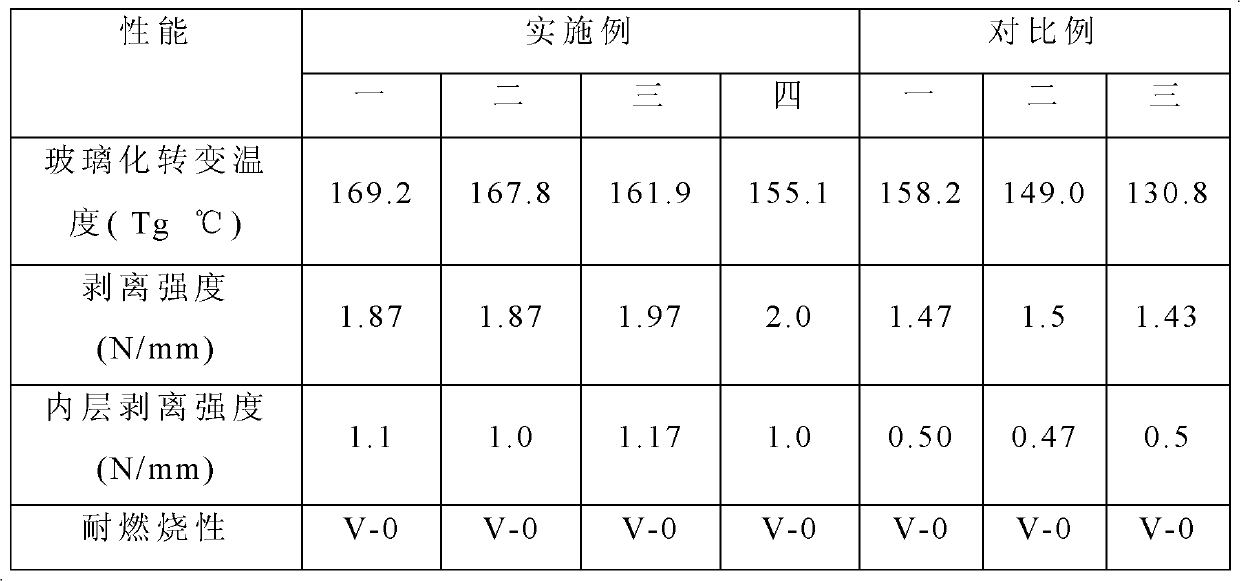

[0038] A halogen-free thermosetting resin composition, by solid weight, comprising the following components, as shown in the following table:

[0039] Table 1: Composition formulation (parts by weight)

[0040]

[0041] Note: In the above table, the basis of parts by weight is based on the total amount of organic solids of epoxy resin (A), phosphorus-containing curing agent (B), and nitrogen-containing curing agent components as 100 parts by weight.

[0042] The meaning of each letter in the table is:

[0043] A epoxy resin:

[0044] A1: Naphthalene ring epoxy resin produced by Nippon Kayaku;

[0045] A2: bisphenol epoxy resin produced by American Hexion Chemical;

[0046] A3: Phosphorus-containing epoxy resin, P=3.0%, EEW=310~340;

[0047] B. Phosphorus-containing curing agent: XZ92741, produced by Dow Chemical in the United States;

[0048] C. Nitrogen-containing curing agent:

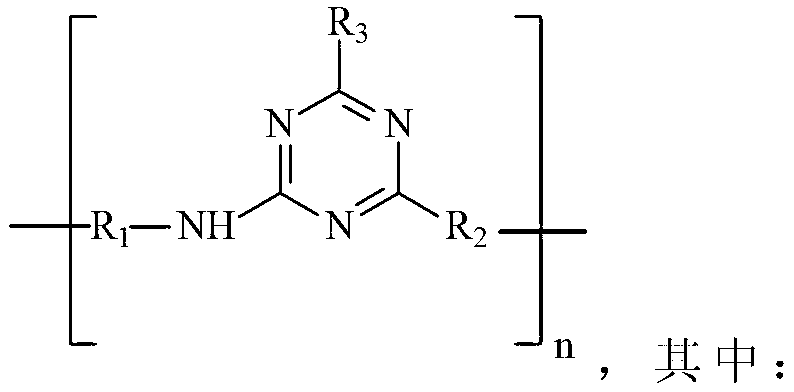

[0049] C1: Wherein, n is an integer from 1 to 5;

[0050] C2: diaminodiphenyl sulfone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com