Suspension stability testing device and testing method

A technology of suspension stability and testing equipment, which is applied in the direction of analyzing materials and instruments, and can solve the problems that the observation method cannot be quantitatively analyzed, it is difficult to trip and start the pump, and the error is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

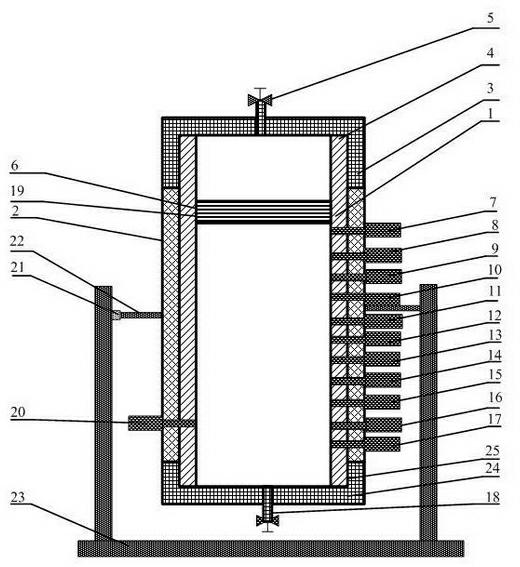

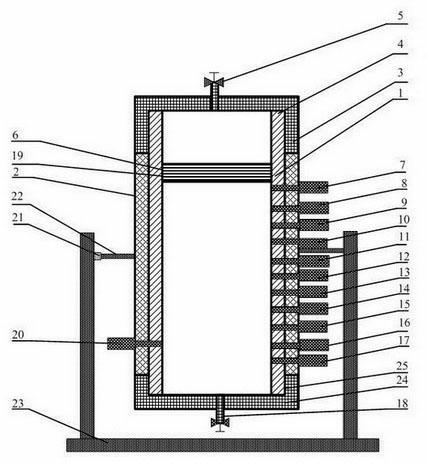

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] A suspension stability testing device, its structural features are: a high-temperature and high-pressure container 1 with a groove on the upper end of the pressure-releasing container O-shaped sealing ring a4, an upper needle-type stop valve 5 installed on the top of the container upper cover 3, and an upper needle-type stop valve 5 The high-pressure resistant pipeline is connected with the constant-pressure constant-speed pump; the high-temperature and high-pressure container 1 is wrapped with a heating jacket 2, and the side wall of the high-temperature and high-pressure container 1 is installed with a temperature sensor 20 and 11 equidistant pressure transmitters 7- 17, and respectively use the temperature sensor signal output line and the high-precision pressure transmitter signal output line to connect with the computer outside the device, the lower part of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com