High-frequency power transformer in primary winding and secondary winding combined structure

A technology of power transformer and secondary winding, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of potential safety hazards and complicated manufacturing process of high-frequency power transformers, achieve high reliability and avoid product insulation strength The effect of reducing and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

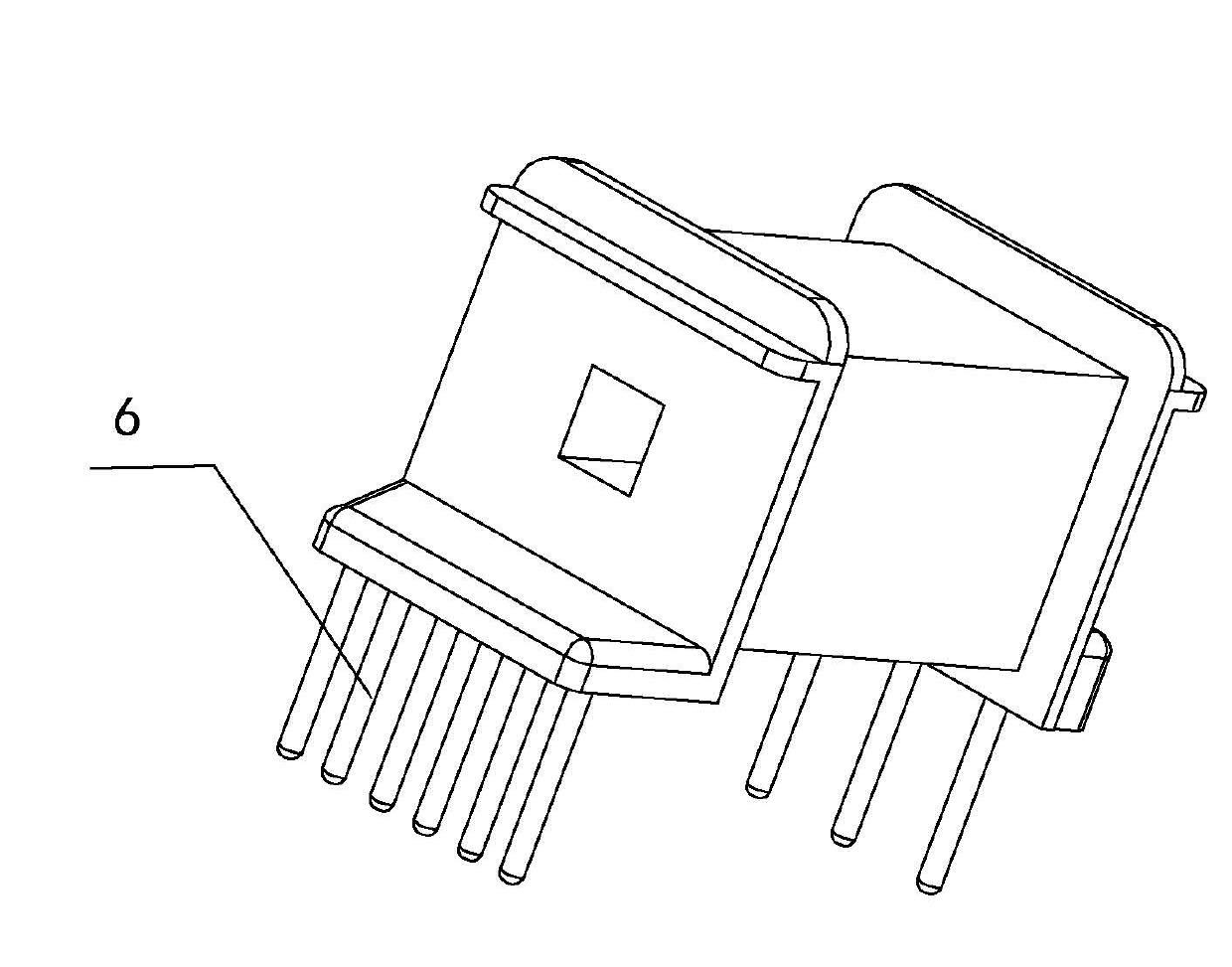

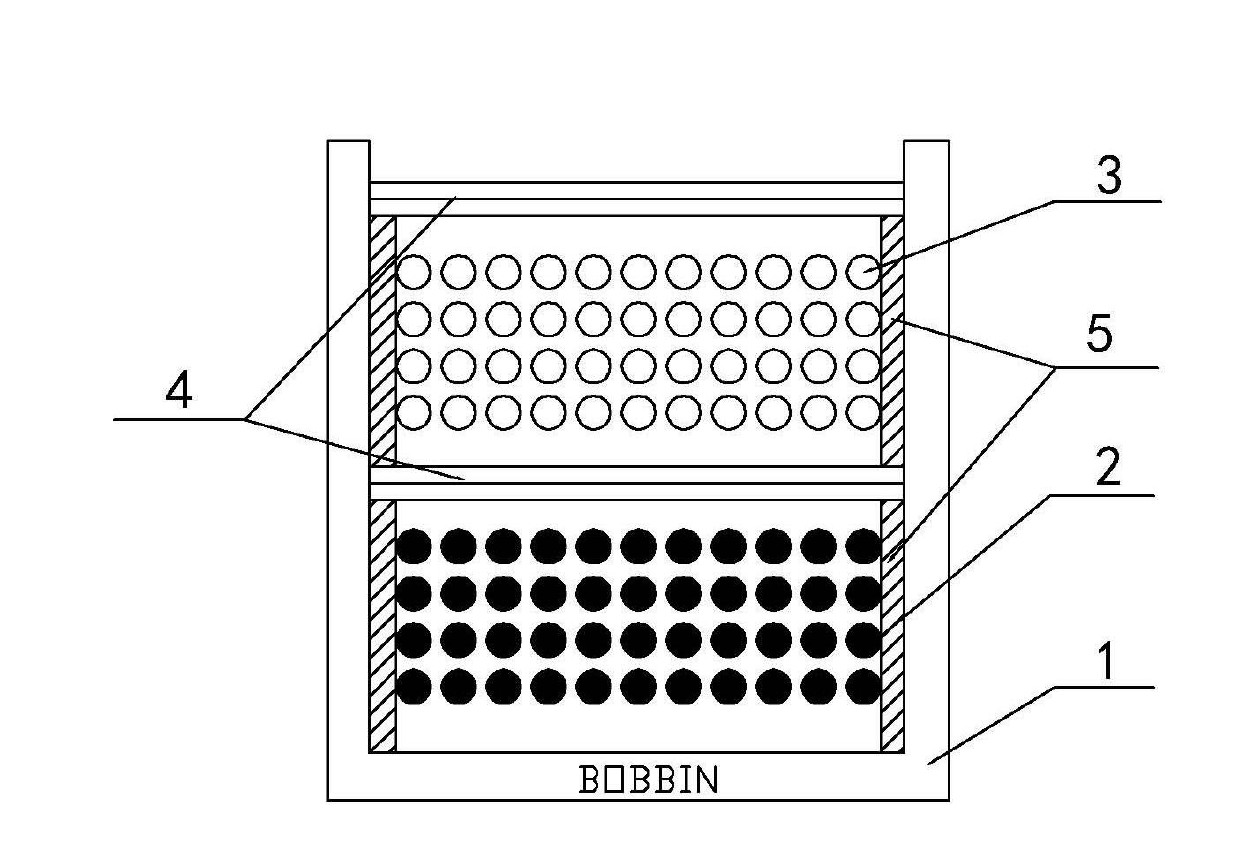

[0034] The high-frequency power transformer in the present invention mainly includes the inner primary winding 10, the secondary winding 3 and the outer primary winding 11, and each winding (including the primary winding and the secondary winding) adopts an independent skeleton, and each winding is combined after winding Together they form a complete transformer. In this embodiment, the bobbin includes an inner bobbin 7, an intermediate bobbin 8 and an outer bobbin 9, wherein the inner primary winding 10 is wound on the inner bobbin 7, the secondary winding 3 is wound on the middle bobbin 8, and the outer primary winding 11 is wound Made on the outer frame 9, the inner frame 7, the intermediate frame 8 and the outer frame 9 are all cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com