Substrate transport device

A substrate conveying and substrate technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

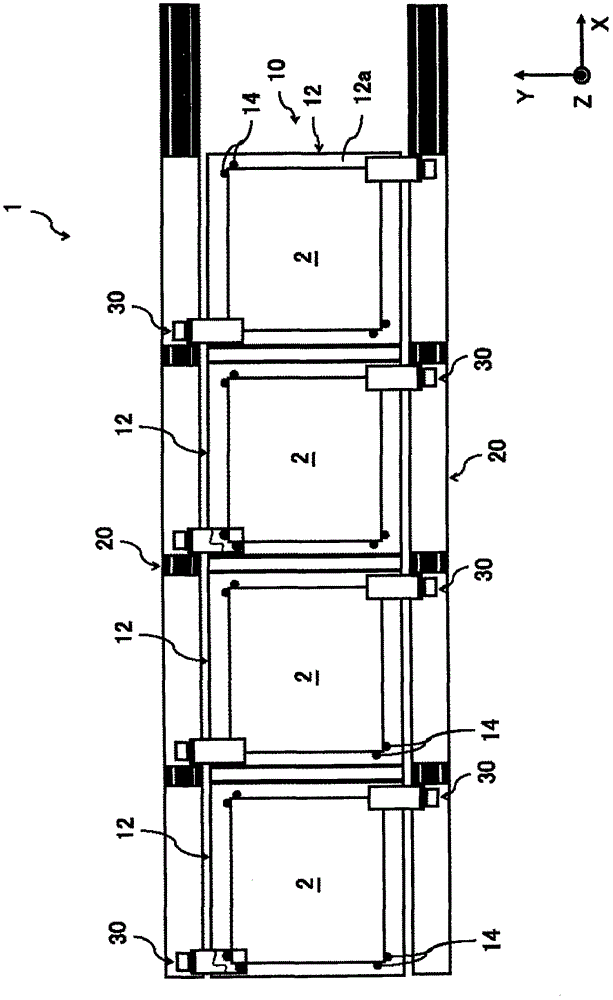

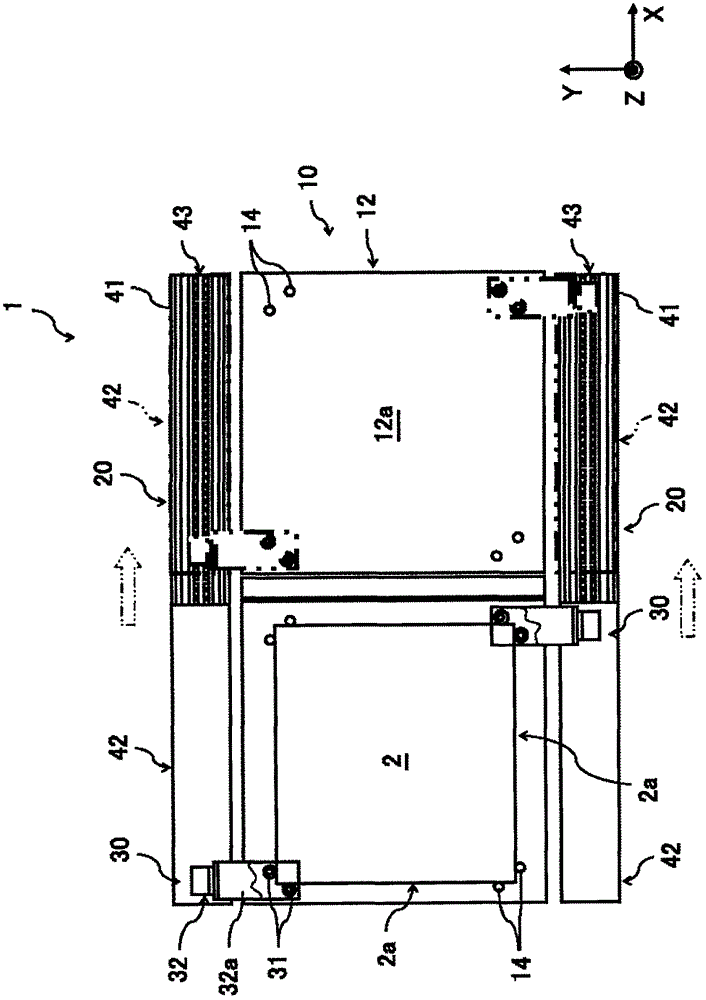

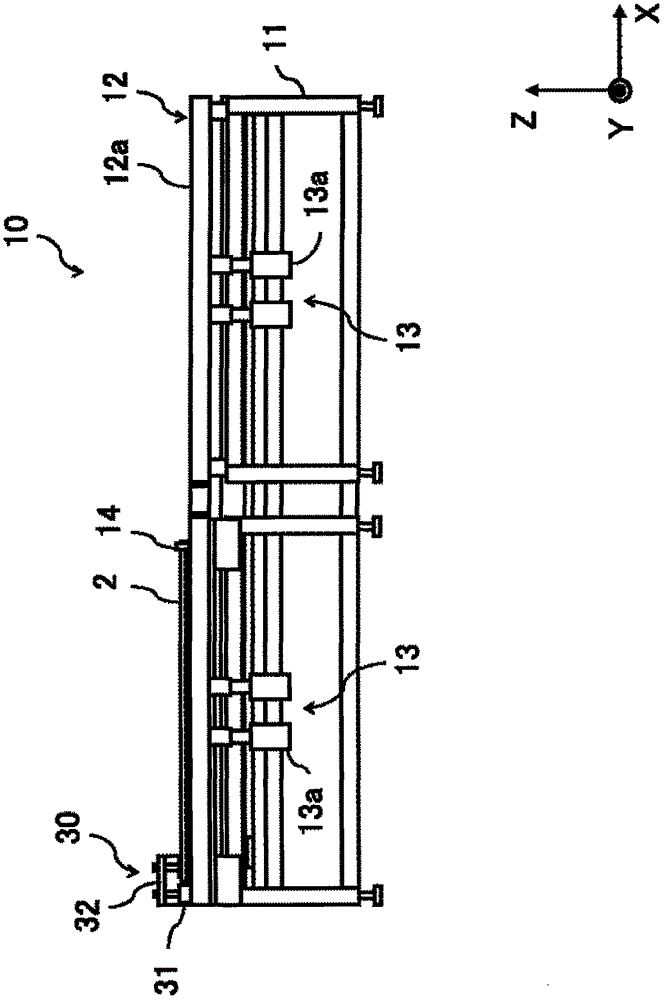

[0054] figure 1 It is a plan view showing one embodiment of a substrate transfer device, figure 2 To enlarge the top view of a unit of the substrate conveying device, image 3 is a side view of a unit of the substrate conveying device, Figure 4 It is a front view of a unit of the substrate transfer device.

[0055] exist Figure 1 to Figure 4 Among them, the substrate transfer device 1 is a device that transfers the substrate 2 in a floating state, and is a device that transfers the substrate 2 from the upstream substrate processing device 1 to the downstream substrate processing device in the next step. For example, when a coating film is formed on the substrate 2 by a coating device that discharges a coating liquid such as a resist liquid, and then the substrate 2 is transported to a drying device that dries the coating film, the substrate supplied from the coating device can be 2. In a floating state, it is transported to the drying device without changing the direct...

Embodiment 2

[0091] In addition, refer to Figure 10 , Figure 11 Another embodiment of the substrate transfer device will be described. here, Figure 10 is a view looking down on a substrate guide 30 according to another embodiment from above, Figure 11 for Figure 10 A-A sectional view of . in the Figure 10 , Figure 11 In the illustrated embodiment, the air cushion 51 of the floating unit 50 is an example formed separately from the substrate abutting portion 34 of the substrate guide main body 31 . In addition, other configurations of the board guide 30 are the same as those in the above-mentioned embodiment, and thus description thereof will be omitted.

[0092] Such as Figure 10 , Figure 11 As shown, the substrate guide 30 includes: a substrate guide body 31 for constraining the substrate 2; a guide supporting portion 32 for supporting the substrate guide body 31; further comprising a floating unit 50 for guiding the substrate The part main body 31 floats from the loading tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com