Grounding resistance reduction process method for sand/gravel area

A sand pebble gravel area technology, which is applied in the field of sand pebble gravel area grounding resistance reduction technology, can solve the problems of high implementation cost and unstable grounding resistance value, and achieve the advantages of convenient construction, best resistance reduction effect and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

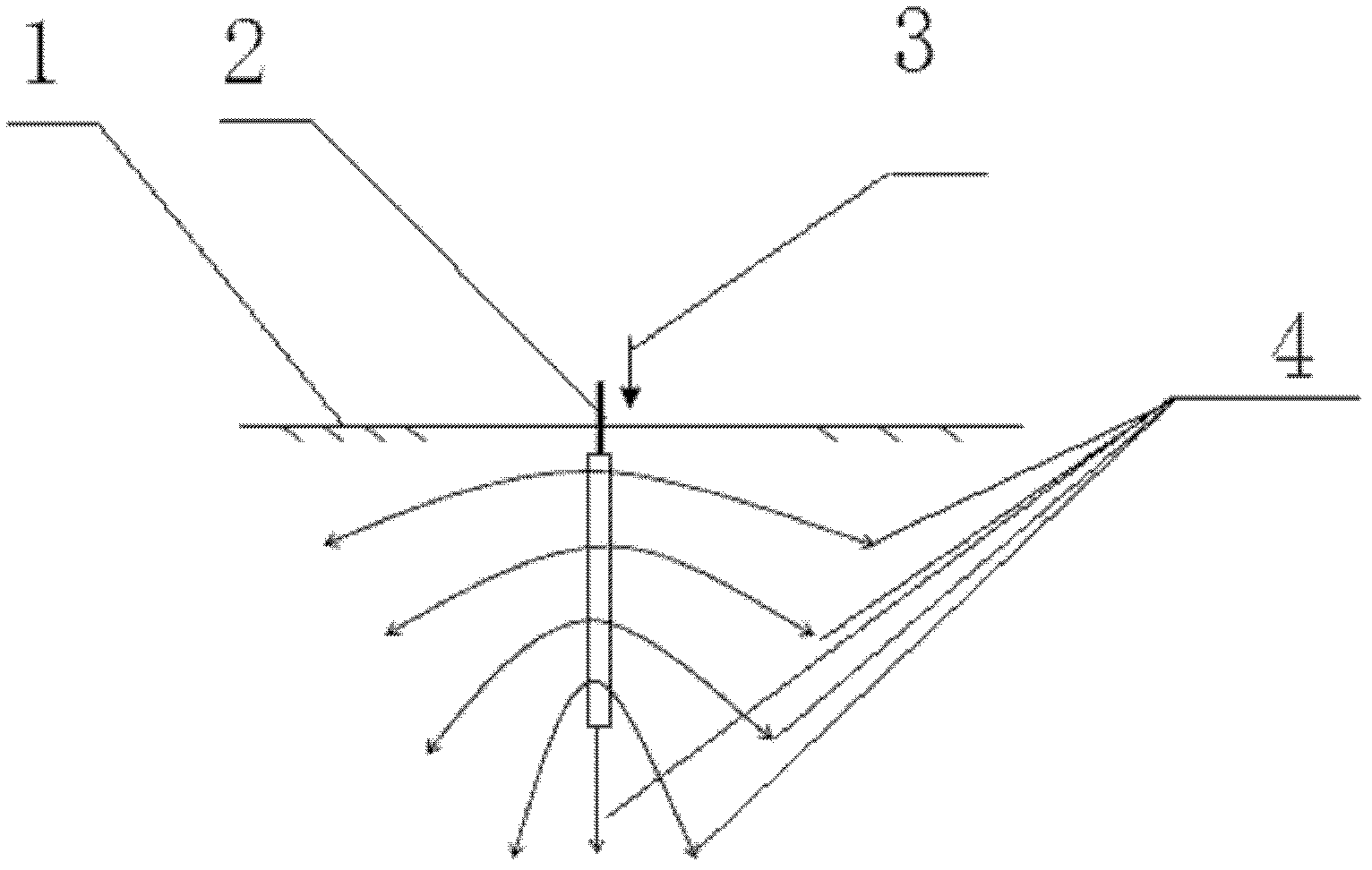

[0047] Such as figure 1 As shown, for the ground 1, the infinite diffusion current 4 spreads across the joint surface of the metal vertical ground electrode 2 and the ground soil. When the current 3 flows out from the vertical ground electrode 2, the current 3 in the vertical ground electrode 2 spreads to all directions of the soil. Surrounding the grounding electrode, the geometric resistance of the soil is the sum of the series resistance of the actual earth shell, gradually outward from where the vertical grounding electrode 2 is located. Close to the vertical ground electrode 2 enclosure has only a small surrounding area and cross-section, and the soil geometry is small, so it has a high electrical resistance. The enclosure progresses to larger regions where the soil geometry increases and thus gradually assumes a lower electrical resistance. Tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com