All-digital intelligent control system of LED plant light filling lamp

A plant light supplement and light control technology, applied in energy-saving control technology, botanical equipment and methods, light sources, etc., can solve the problems of insufficient use of LED light sources, digital, intelligent, centralized control, insufficient and excessive plant light supplement, etc. Achieve the effect of increasing the applicable range and improving photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

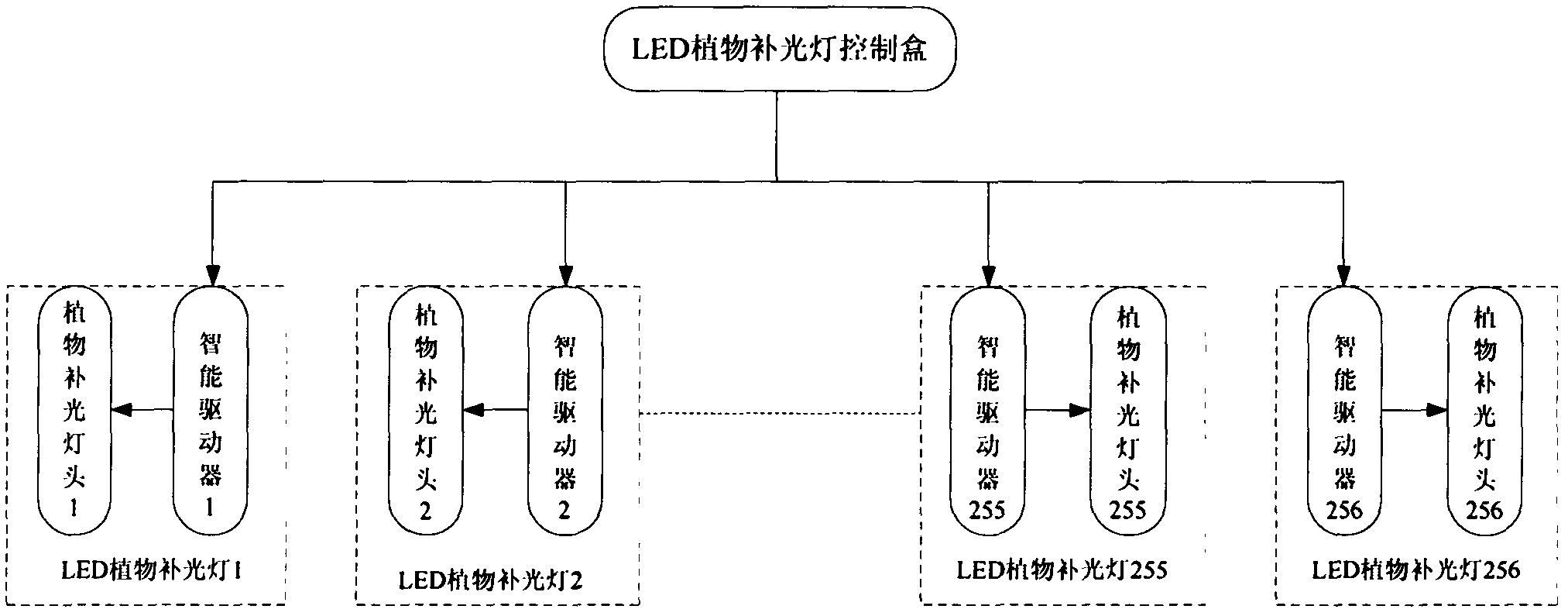

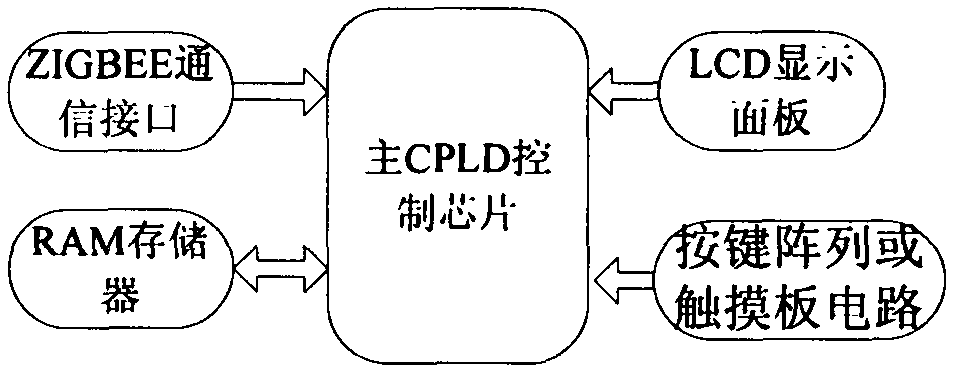

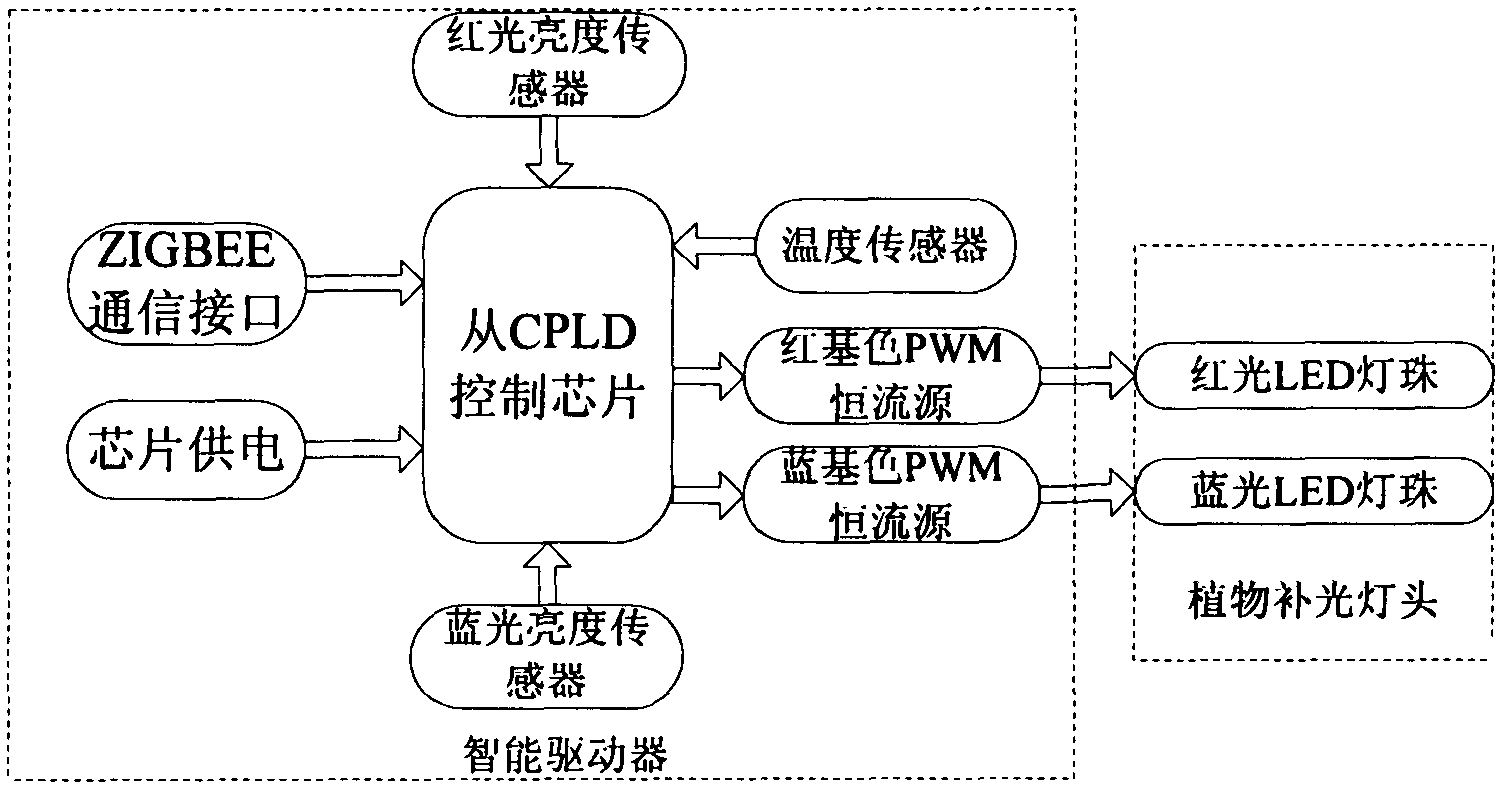

[0021] The LED plant supplementary light control system of the present invention includes an LED plant supplementary light control box, an intelligent driver and an LED plant supplementary light lamp head such as figure 1 . Among them, the intelligent driver and the LED plant fill light head are integrated together in the specific implementation, and the single lamp after integration is called the LED plant fill light. According to different design capacities, the control box can be connected to several LED plant supplementary lights, and the present invention is designed to be connected to 256 LED plant supplementary lights. Each plant supplementary light can determine a unique communication address according to the order in which it is located, so that the control box can access the internal working parameters of each plant light through the ZIGBEE control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com