Method of manufacturing cast metal products, and manufacturing plant

A manufacturing method and technology of casting method, applied in the direction of manufacturing tools, foundry workshop, casting equipment, etc., can solve the problems of different technical ideas and two casting methods have not been considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

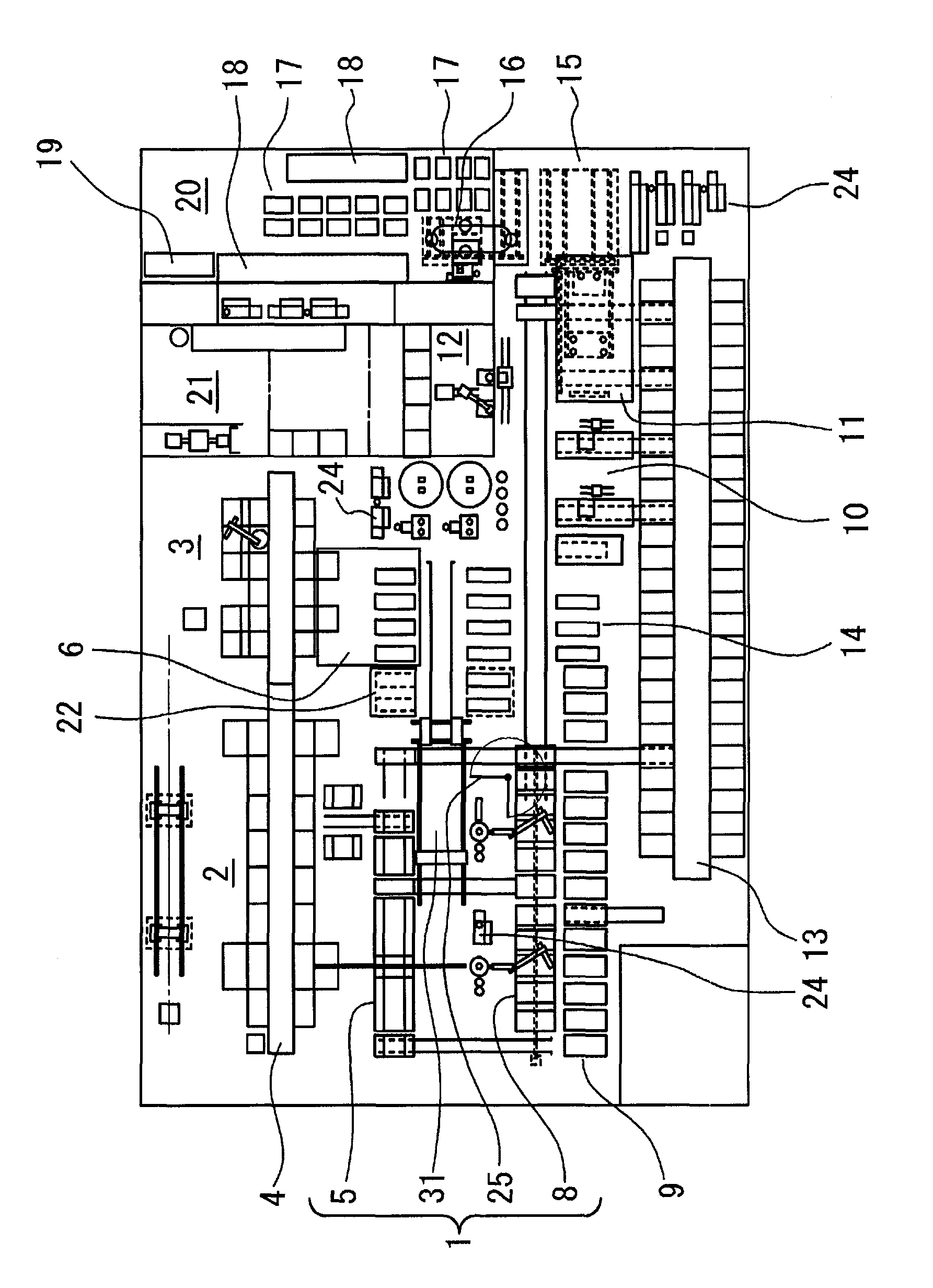

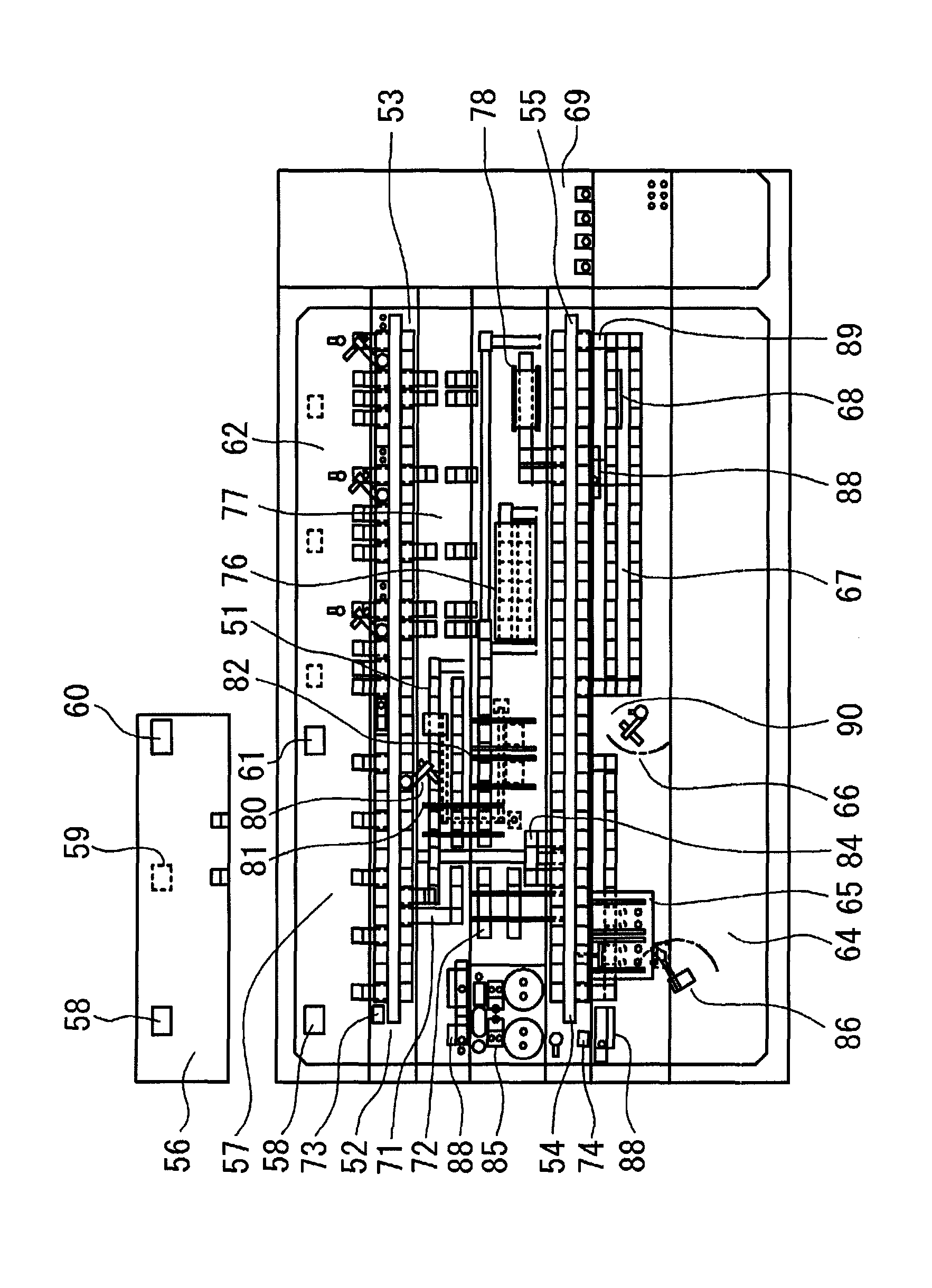

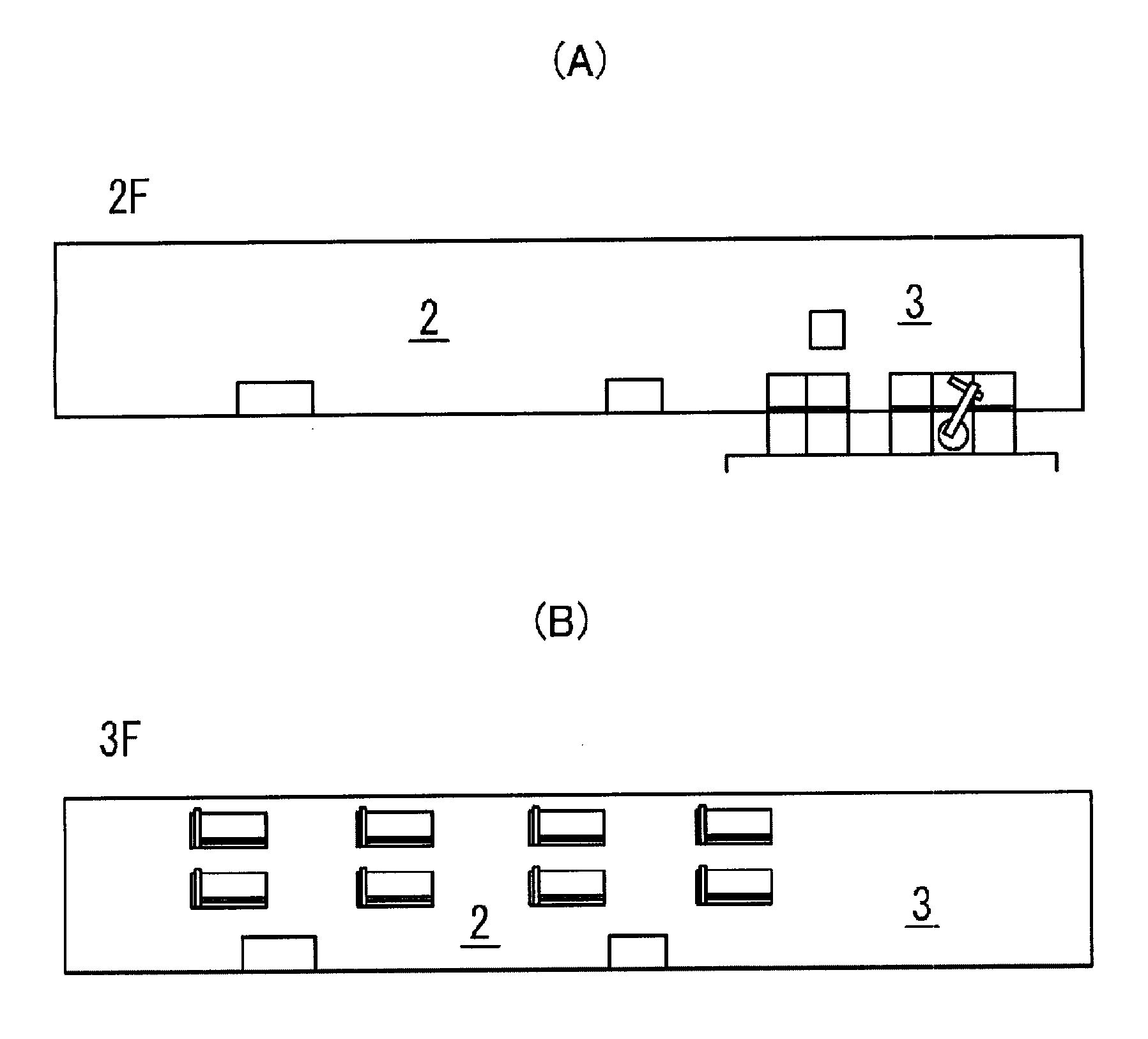

[0034] The method of manufacturing cast products according to the present invention is characterized in that, by sharing the mold molding line in one factory, and simultaneously installing the casting line of the foam mold casting method and the casting line of the wooden mold casting method, it is possible to include the manufacturing object. According to the judgment factors including the shape, material and production batch of the casting product, choose one of the foam plastic solid mold casting method and the wooden mold casting method to manufacture the casting product, Figure 1 to Figure 3 It is a schematic plan view showing an example of the layout of a casting factory according to the present invention for carrying out this method.

[0035] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. In one embodiment, the factory involved in the present invention is as figure 1 As shown, a composite multifunctional mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com