Thermosyphon reboiler for the denitrogenation of liquid natural gas

A liquid natural gas, thermosyphon technology, applied in the field of nitrogen separation, can solve the problem of limited flexibility, achieve the effect of large flexibility, increase process flexibility, save cost and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

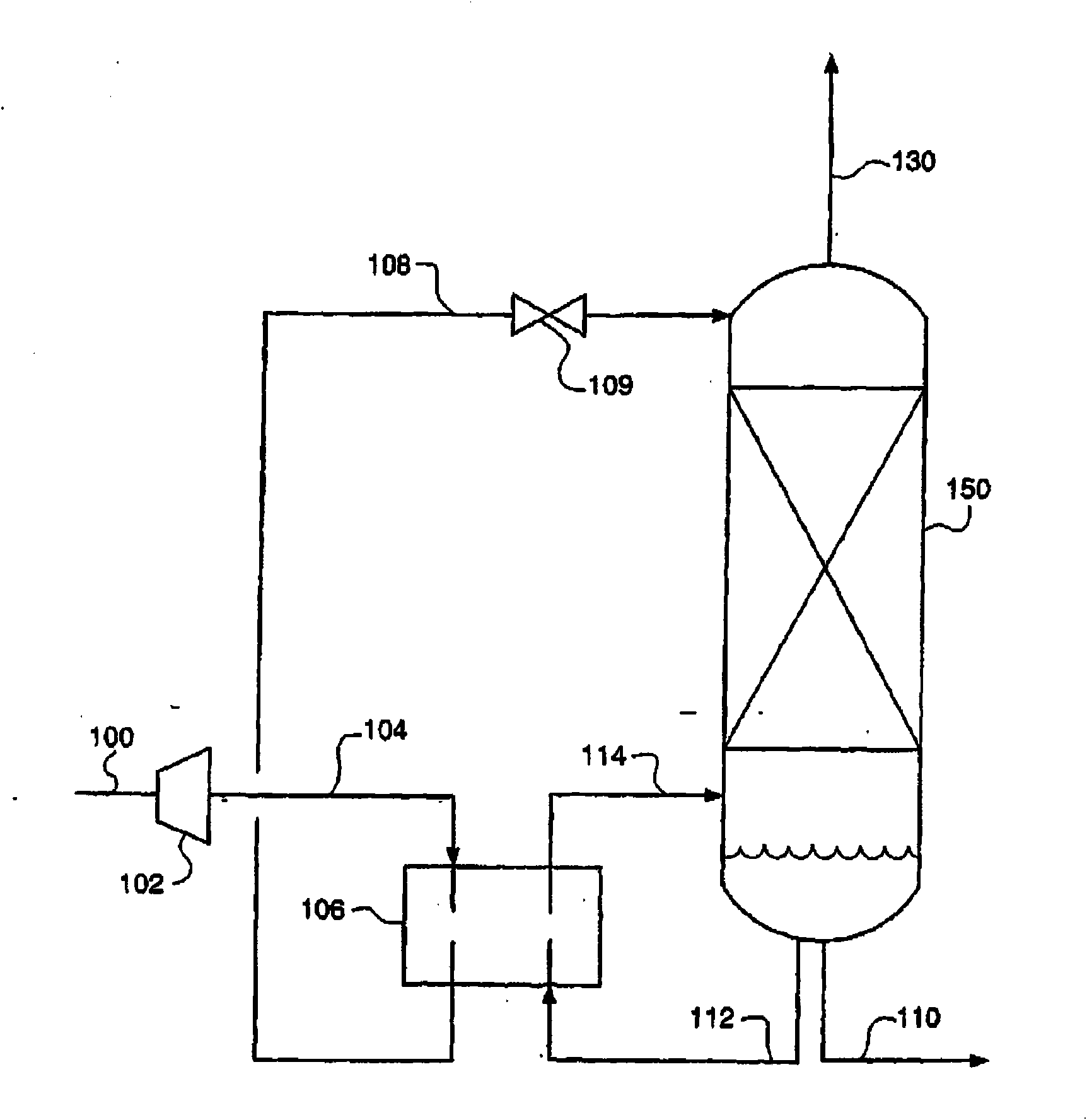

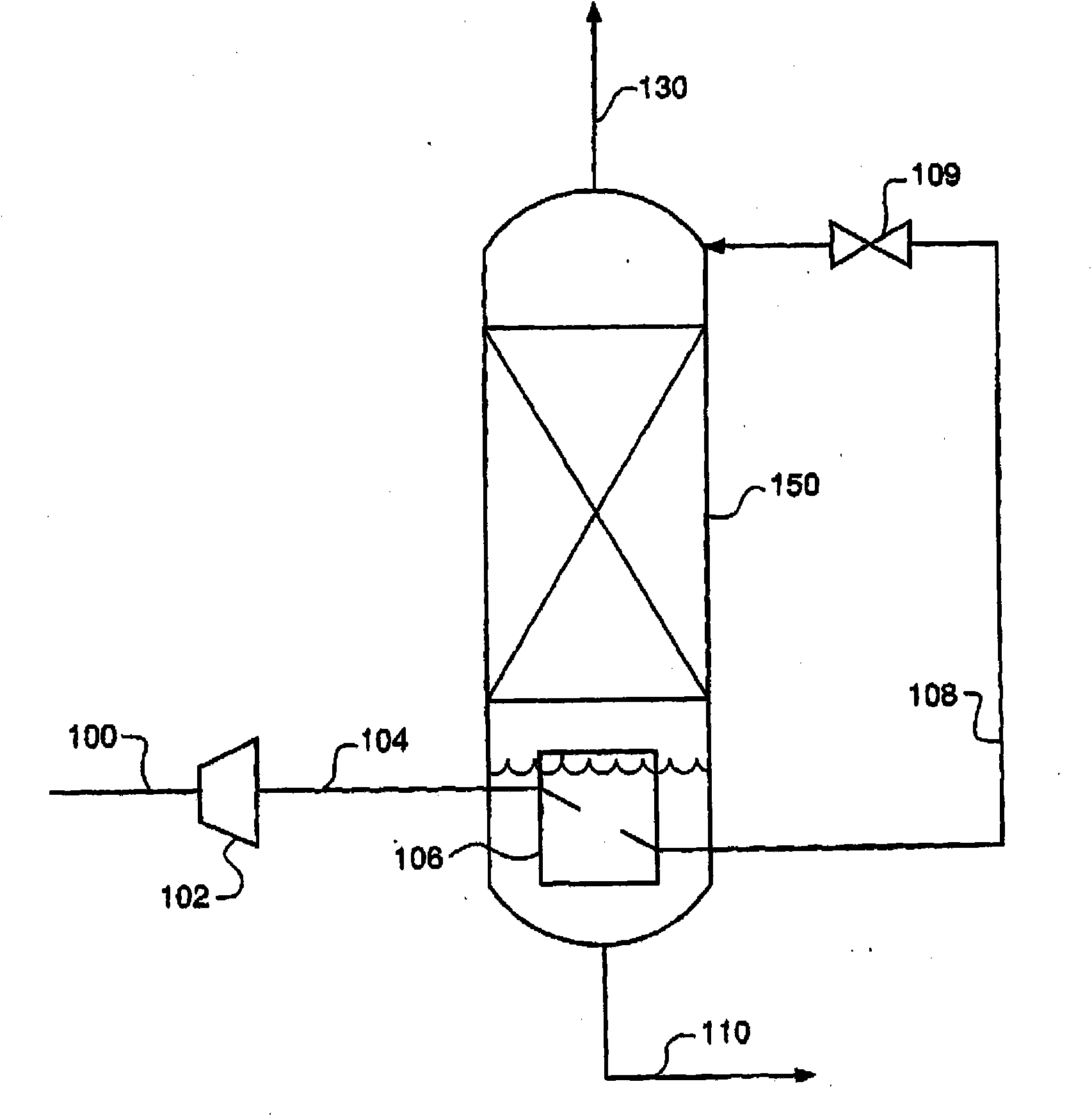

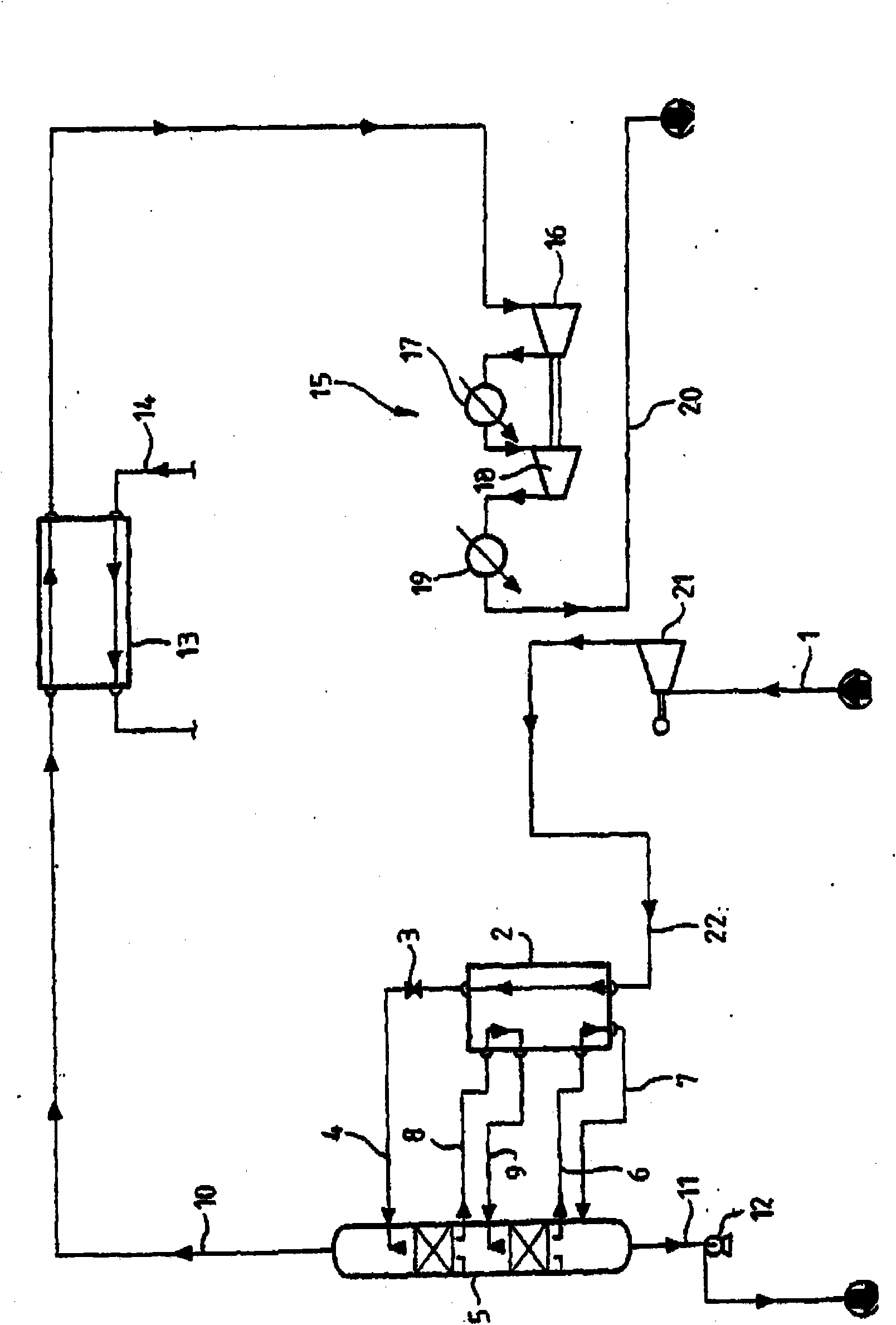

[0046] In order to demonstrate in more detail some important differences between the present invention and the prior art, the ASPEN process simulator was used to run the entire natural gas liquefaction process, two embodiments of the present invention ("the process") and the US -A-5421165 disclosed in the process for comparison. The basis of the comparison is the same LNG product and the fulfilled fuel balance (the amount of LNG product flash required to drive the gas turbine used to drive the process). Corresponding reference numbers used in this example refer to the aforementioned figure 1 and US-A-5421165 (see the figure 1 ).

[0047] This process method

[0048] A. Recycling rate: 2.9

[0049] refer to figure 1 , with the expansion in the dense fluid expander 102, the low-pressure LNG stream 104 has a flow rate of 125,470 lbmol / h (56,912 kgmol / h), a pressure of 71.78 psia (494.9 kPa), and a temperature of -242.9°F (-152.7°C) and contains 2.96% N 2 , 95.47% methane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com