Fully-automatic garbage processor

A garbage disposer, fully automatic technology, applied in the direction of grain processing, etc., can solve the problems of insufficient use of the centrifugal effect of the rotary rotary cutter, poor garbage disposal quality, low degree of automation, etc. Noise reduction and stability improvement, simpler and simpler garbage disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below in conjunction with the examples, the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

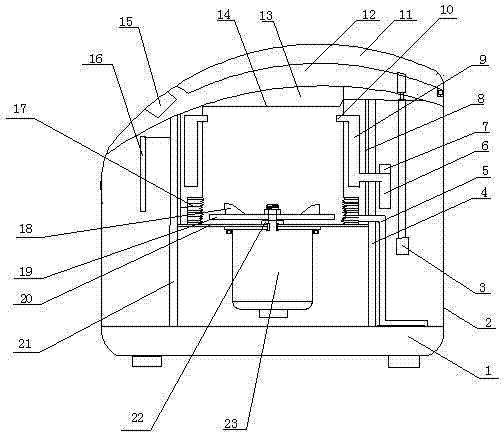

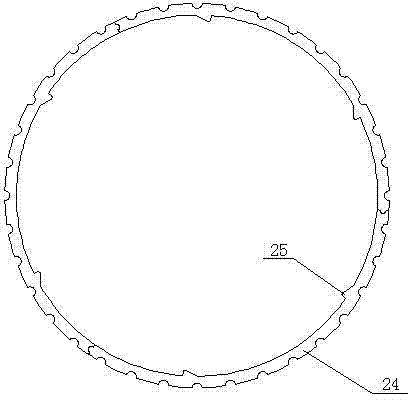

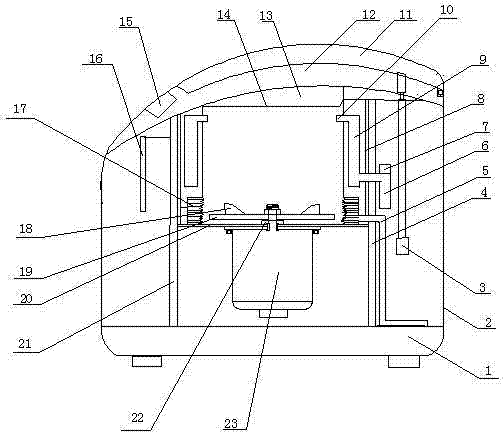

[0014] see figure 1 , the housing 2 of the automatic garbage disposer is fixedly connected with the front vertical partition 21, the rear vertical partition 4 and the middle horizontal partition 20 integrally with it, and four non-interfering partitions are formed by the partitions. independent space. A motor 23 is installed in the lower space of the middle transverse partition 20, and the output shaft of the motor 23 passes through the middle transverse partition 20, and a sealing sleeve 22 is installed between the output shaft and the middle transverse partition 20, and a rotary cutterhead 19 is fixed on the output shaft. . A crushing chamber 8 is installed in the upper space of the middle transverse partition 20. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com