Laser irradiation apparatus, laser irradiation method, and insulating film forming apparatus

A technology of laser irradiation and laser light source, used in laser parts, laser welding equipment, electrical components, etc., can solve the problems of difficulty in realizing the aperture of the packaging substrate, deterioration of roundness, and failure to achieve practicality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

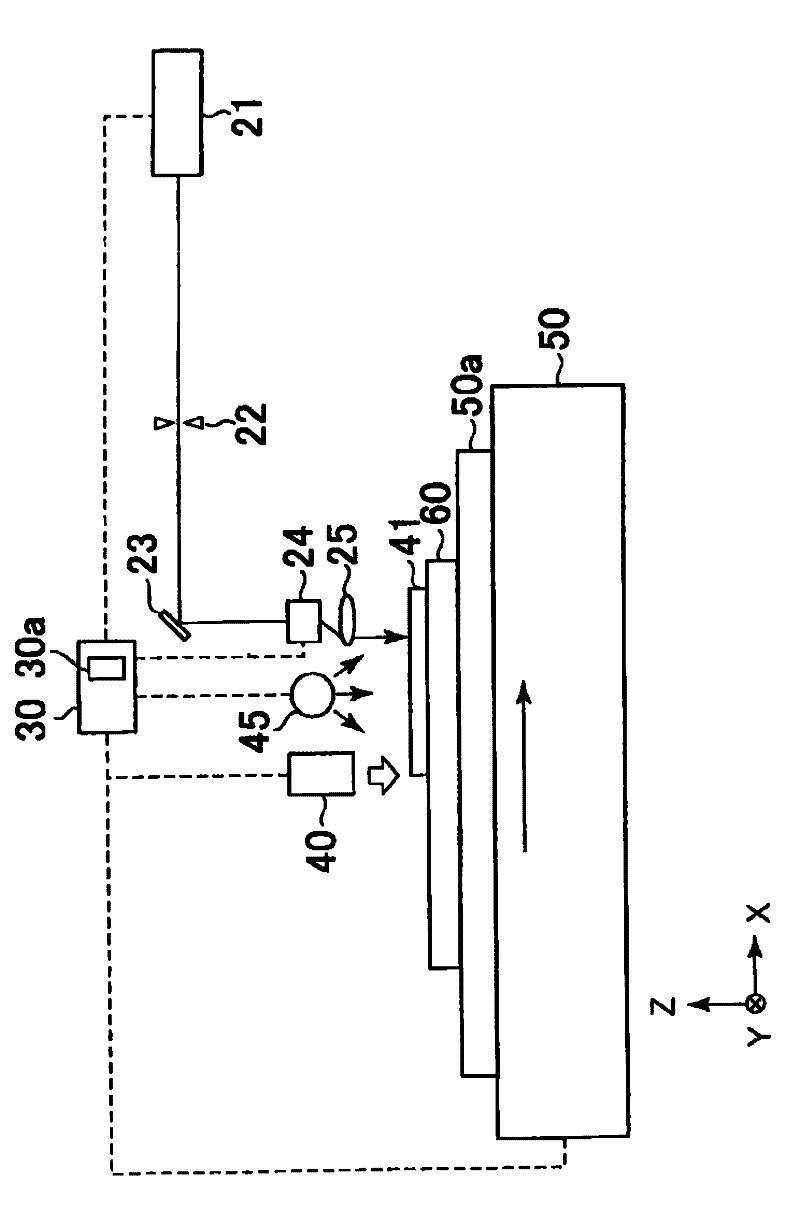

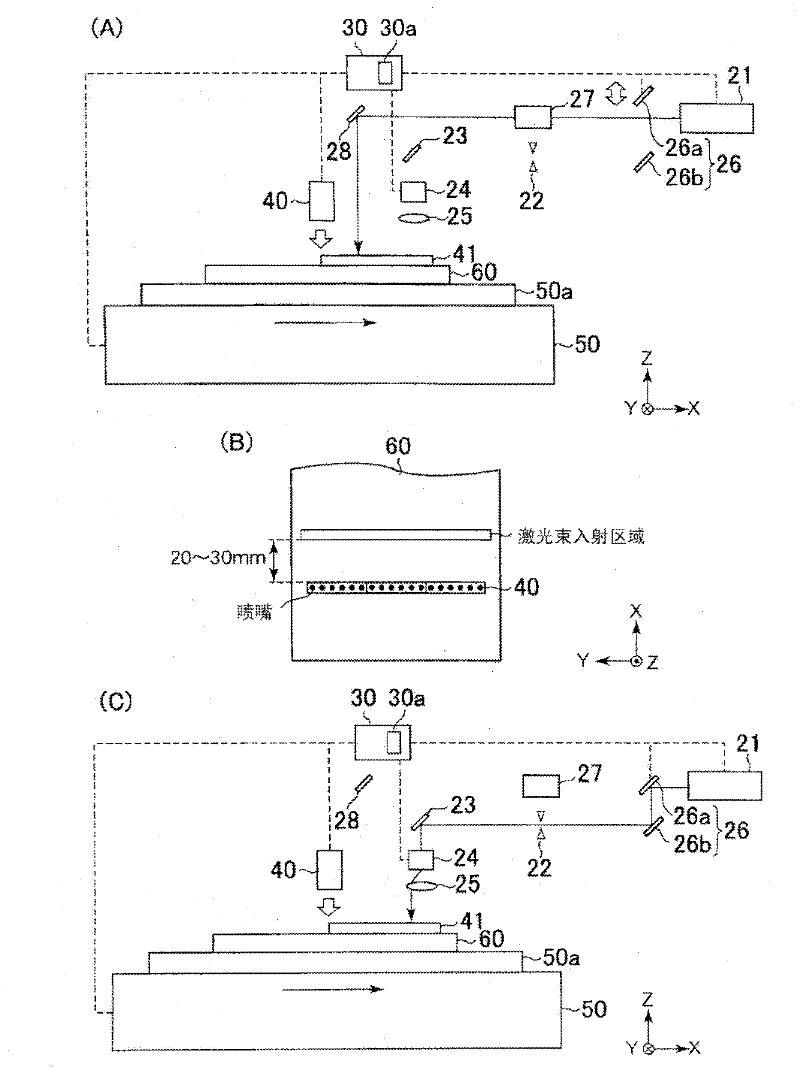

[0035] figure 1 It is a schematic diagram showing the laser irradiation device according to the first embodiment. The laser irradiation device based on the first embodiment includes a laser light source 21, a mask 22, a folding mirror 23, a current scanner 24, an fθ lens 25, a control device 30, an inkjet printer 40, a lamp light source 45, and a stage 50. constitute.

[0036] The control device 30 includes, for example, a storage device 30a as a memory. The stage 50 includes a chuck plate 50 a for sucking and holding a printed wiring board (substrate) 60 as a holding object, and can move the printed wiring board 60 in the in-plane direction. The stage 50 is, for example, an XYθ stage. A solder resist pattern was formed on the printed wiring board 60 held on the stage 50 by the partial coating method using the laser irradiation apparatus according to the first embodiment.

[0037] The stage 50 moves the printed wiring board 60 in the X-axis direction at a constant speed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com