Automatic locking mechanism and automatic locking filature provided with same

An automatic locking, pneumatic screwdriver technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of low speed, easy to heat signal controllability, can not be used in the field of automatic locking and payment, to improve the level of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

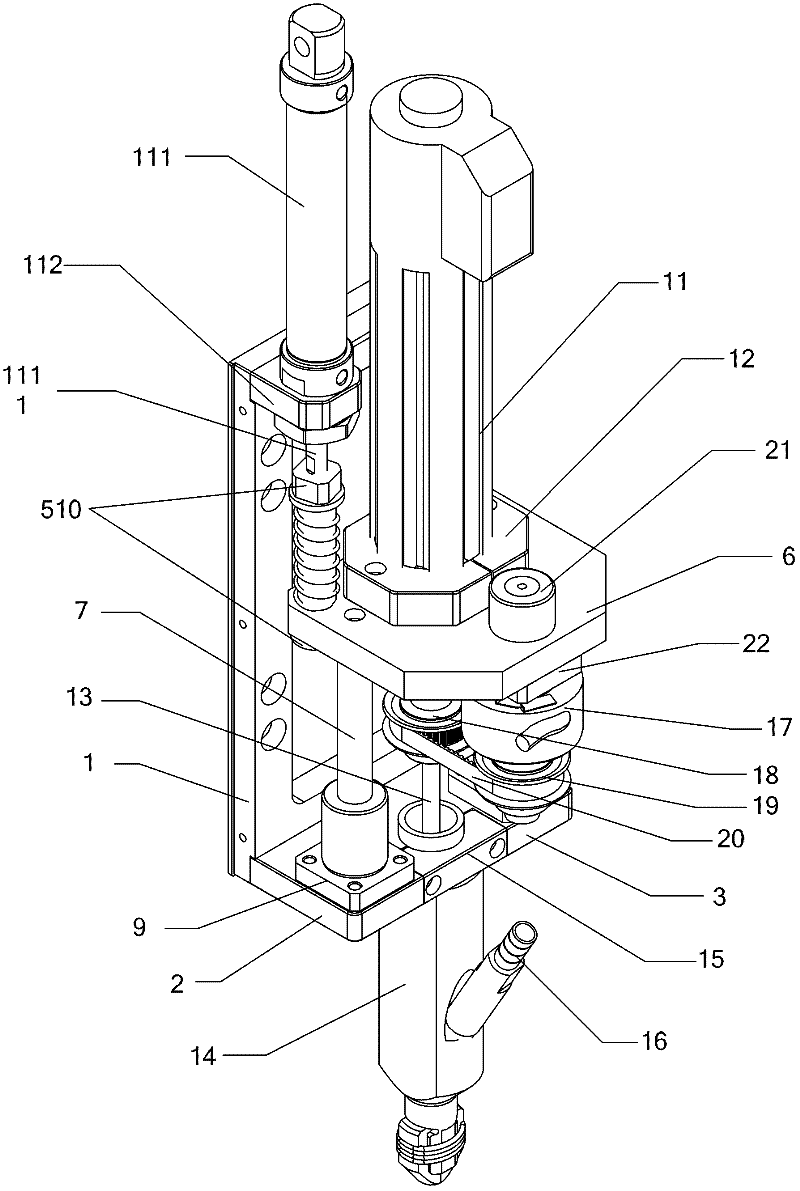

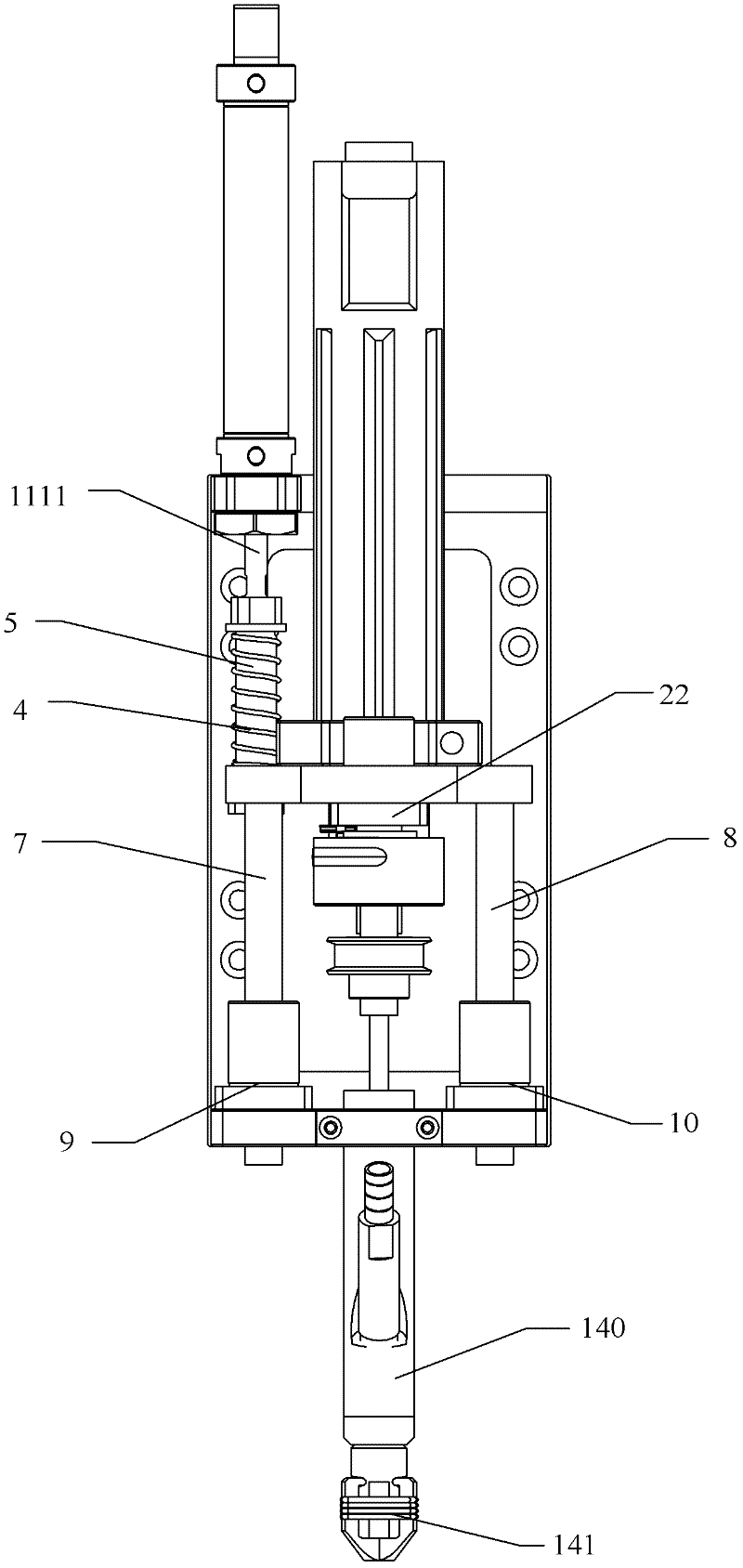

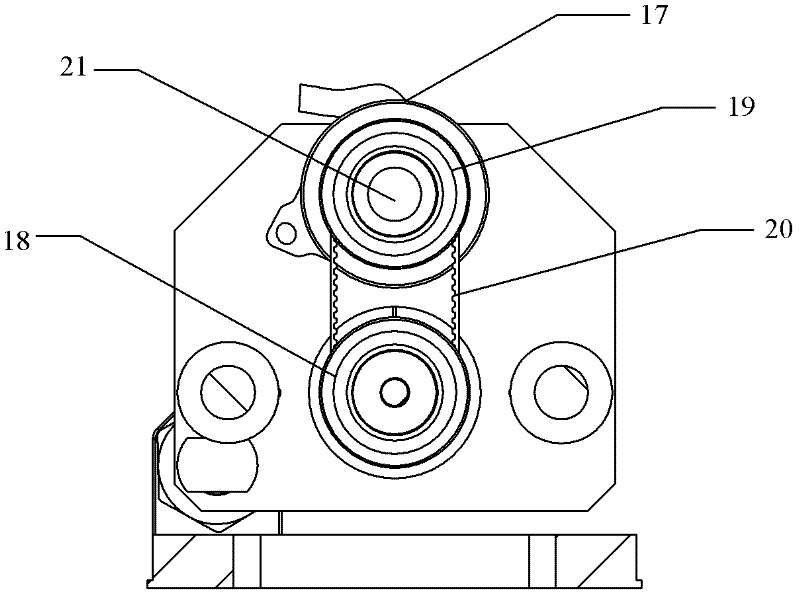

[0029] like figure 1 and figure 2 As shown, the automatic locking mechanism of the present invention mainly includes a mounting base plate 1, a first bearing mounting plate 2, a second bearing mounting plate 3, a pushing assembly, a pressing assembly, a screw-in assembly and a control assembly, and the pushing assembly drives the pressing assembly Moving vertically downward, the compression component drives the screw-in component to engage the compression screw, the screw-in component screws into the locking screw, and the control component controls the stop of the screw-in component when it detects that the screw is locked and stops rotating.

[0030] The push assembly is fixed on the installation base plate 1, the push assembly includes a locking cylinder 111 and a cylinder mounting plate 112, the locking cylinder 11 includes a push rod 1111, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com