Device for rapid replacement of blast furnace cooling wall through external jacking without lowering stockline and construction method thereof

A technology of cooling stave and blast furnace, applied in the direction of cooling device, etc., can solve the problem of needing to drop the material line, re-line, and other parts cannot be kept still, so as to shorten the construction time, save materials, reduce the damage of the cooling stave and the furnace body. The effect of quench heat and quench effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

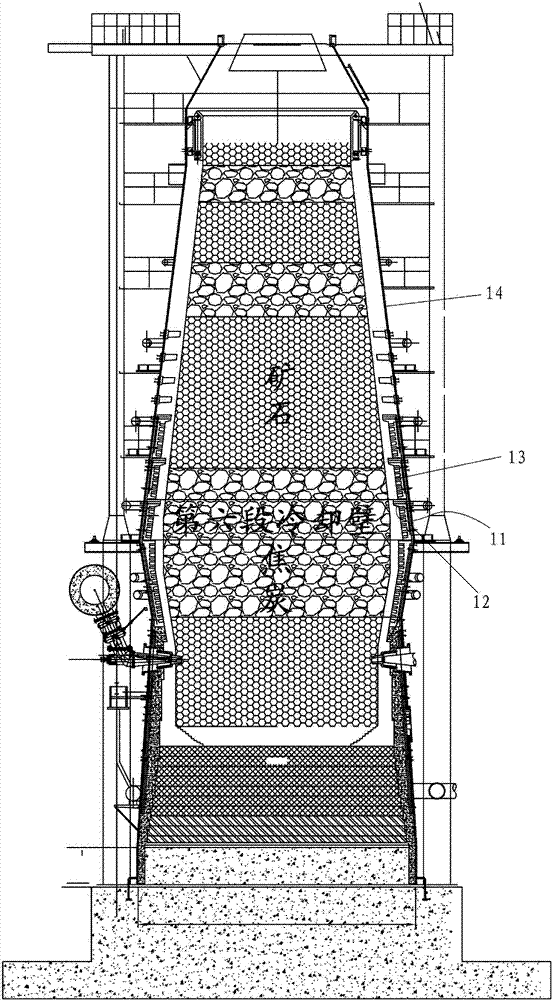

[0053] figure 1 It is a panoramic view of the blast furnace, which is filled with various iron-making raw materials (including coke, sinter, lump ore, limestone, pellets, etc.). figure 1 What the sign 12,13 represent in is stave, and it is arranged on furnace shell 14 insides.

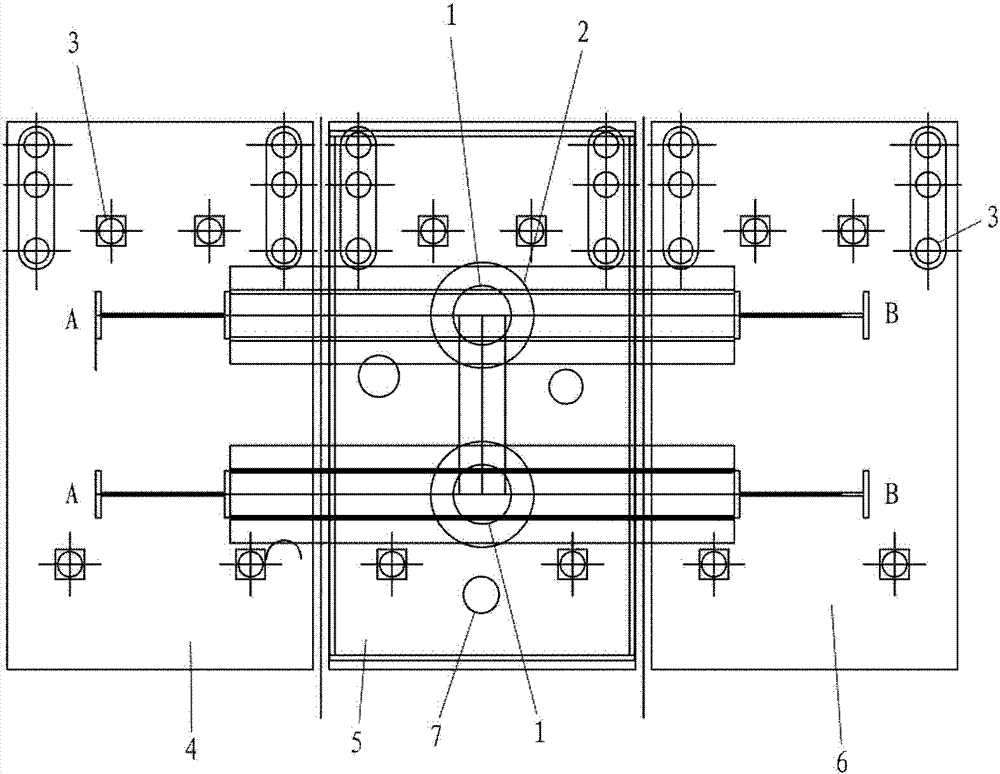

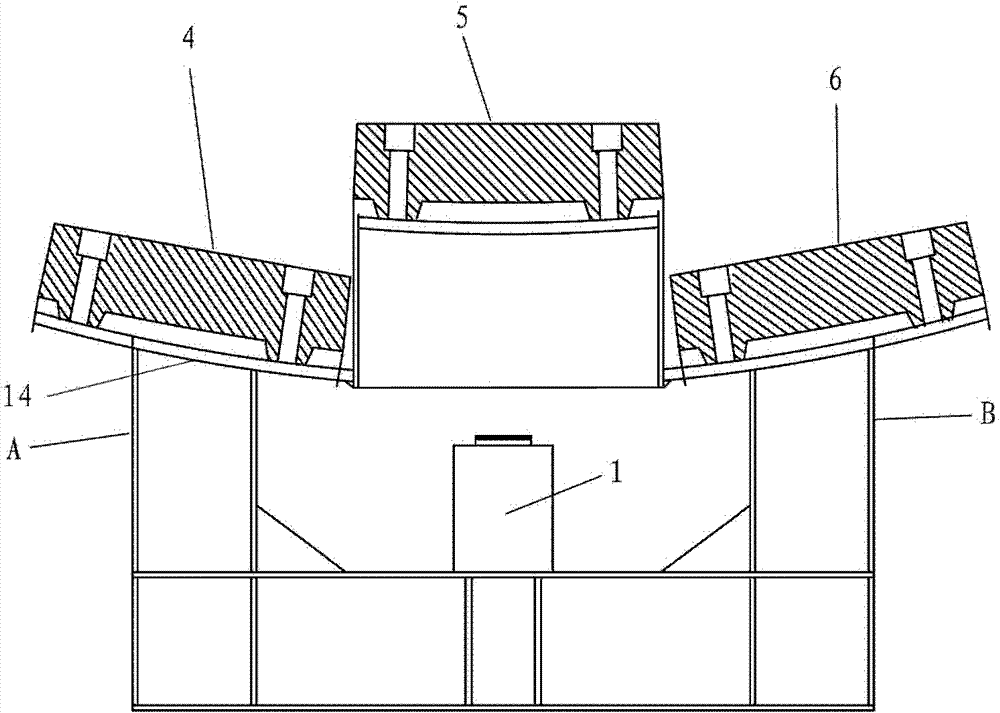

[0054] figure 2 is a front view showing a top frame structure provided with a hydraulic press, image 3 It schematically shows the top view of the hydraulic press set on the top frame pushing into the old furnace shell and retracting from the old furnace shell, Figure 4 Schematically shows the side view of the hydraulic press that is arranged on the top frame jacking into the old furnace shell (for the sake of clarity, the baffle plate is not shown in the figure), Figure 5 It is a side view of the hydraulic press installed on the top frame jacking into the old furnace shell with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com