Production method of low-sulfur steel

A production method and low-sulfur steel technology, applied in the manufacture of converters, etc., can solve the problems of increasing carbon and nitrogen in molten steel, unfavorable desulfurization, limited sulfur control capacity of converters, etc., and achieve the effect of avoiding carbon and nitrogen increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the embodiments.

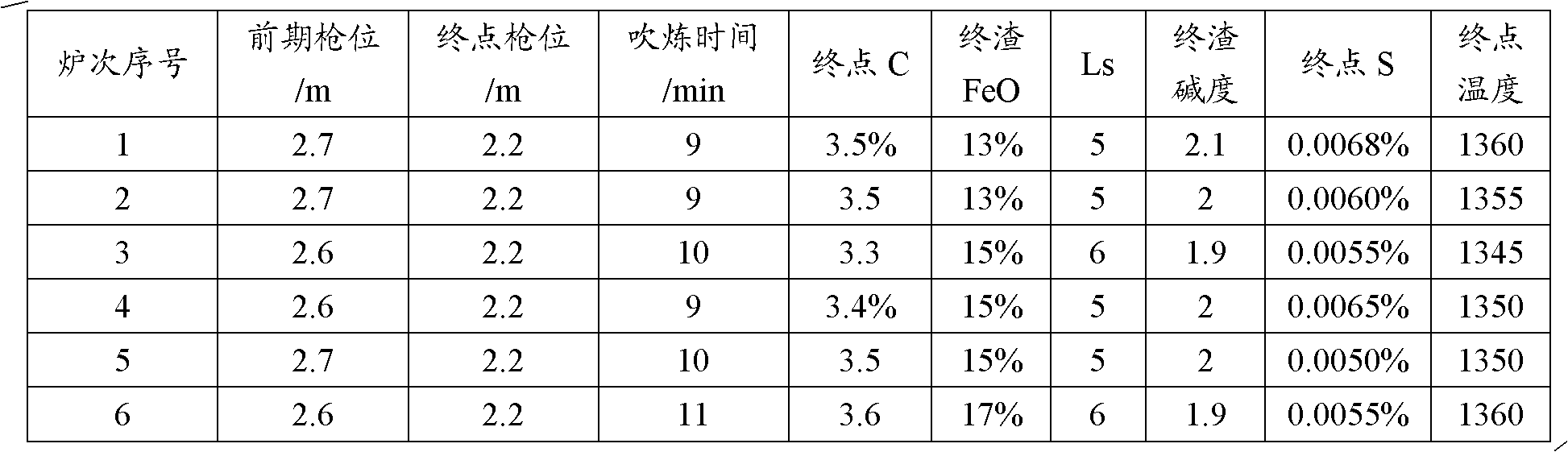

[0022] In the embodiment of the present invention, taking 6 furnaces as an example, a method for producing low-sulfur steel using a double converter process is provided, which specifically includes the following steps:

[0023] In step (1), the molten iron is desulfurized by KR, and a desulfurizing agent is added after removing slag from the molten iron. The desulfurizing agent is a mixture of lime and fluorite, the mass ratio of lime and fluorite is 10:1, and the amount of desulfurizing agent added is 6kg / t; After KR injection and stirring treatment, the slag removal rate of molten iron after KR desulfurization treatment is 95%. After KR desulfurization treatment, S in molten iron is less than 0.002%. Dephosphorization converter. The change of sulfur content in molten iron and the amount of desulfurizer added during KR treatment are shown in Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com