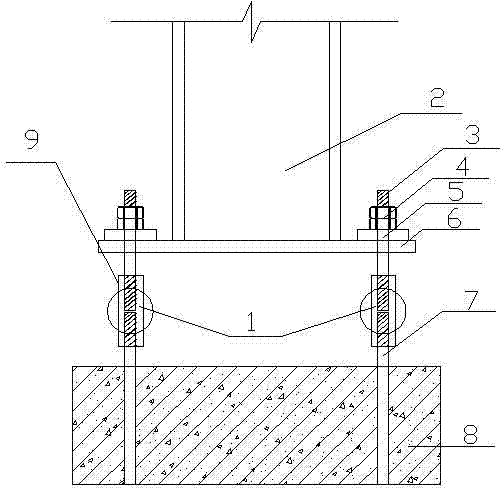

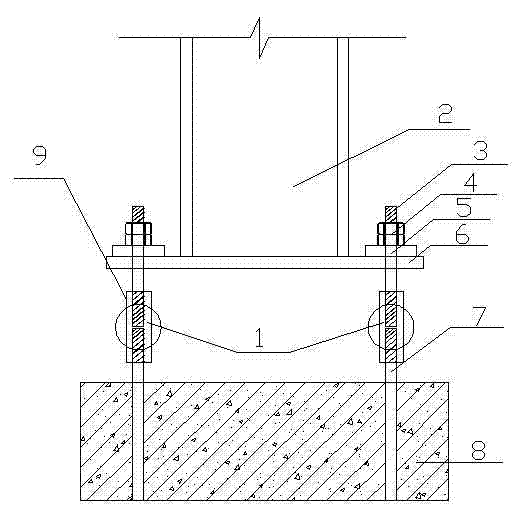

Building steel-column foundation lengthening bolt and lengthening method thereof

A technology of long bolts and steel columns, which is used in infrastructure engineering, construction material processing, construction, etc., can solve the problems of inability to ensure the strength of bolt rods, unsafe and reliable processing methods, and long on-site construction period, and achieve the construction period. Short, simple and easy to operate, low labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

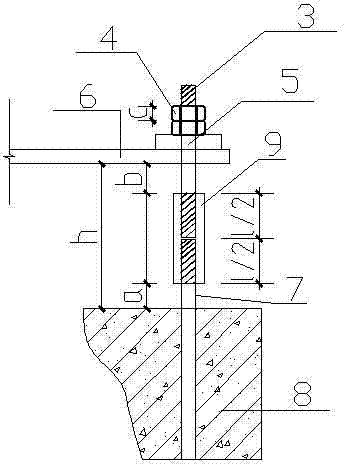

[0036] Example 2, a method for extending bolts for the steel column foundation of a factory building. This method is based on the principle of equal tensile strength and is operated with reference to the construction industry standard JGJ 107-2003 general technical regulations for mechanical connection of steel bars. The original embedded bolt 7 The strength of the nut and the bolt shank matches (equal strength), therefore, the processed steel sleeve 9 calculates the outer diameter D of the steel sleeve 9 according to the principle that the tensile capacity in the length direction is greater than or equal to the tensile capacity of the pre-embedded bolt shank:

[0037] [π(D / 2) 2 -π(d / 2) 2 ]·f cylinder ≥ π(d / 2) 2 ·f bolt

[0038] 1) Get the formula: D≥d(1+f bolt / f cylinder) 1 / 2 ...

[0039] In the formula: D is the outer diameter of the steel sleeve; d is the diameter of the embedded bolt 7 and the external bolt; f sleeve: the design value of the tensile strength of the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com