Variable damping control and buffering system

A damping control and buffering system technology, applied in springs, shock absorbers, springs/shock absorbers, etc., can solve the problems of high machining accuracy, large space occupation, oil leakage, etc., and achieve effective damping adjustment and control, pressure control Simplicity, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

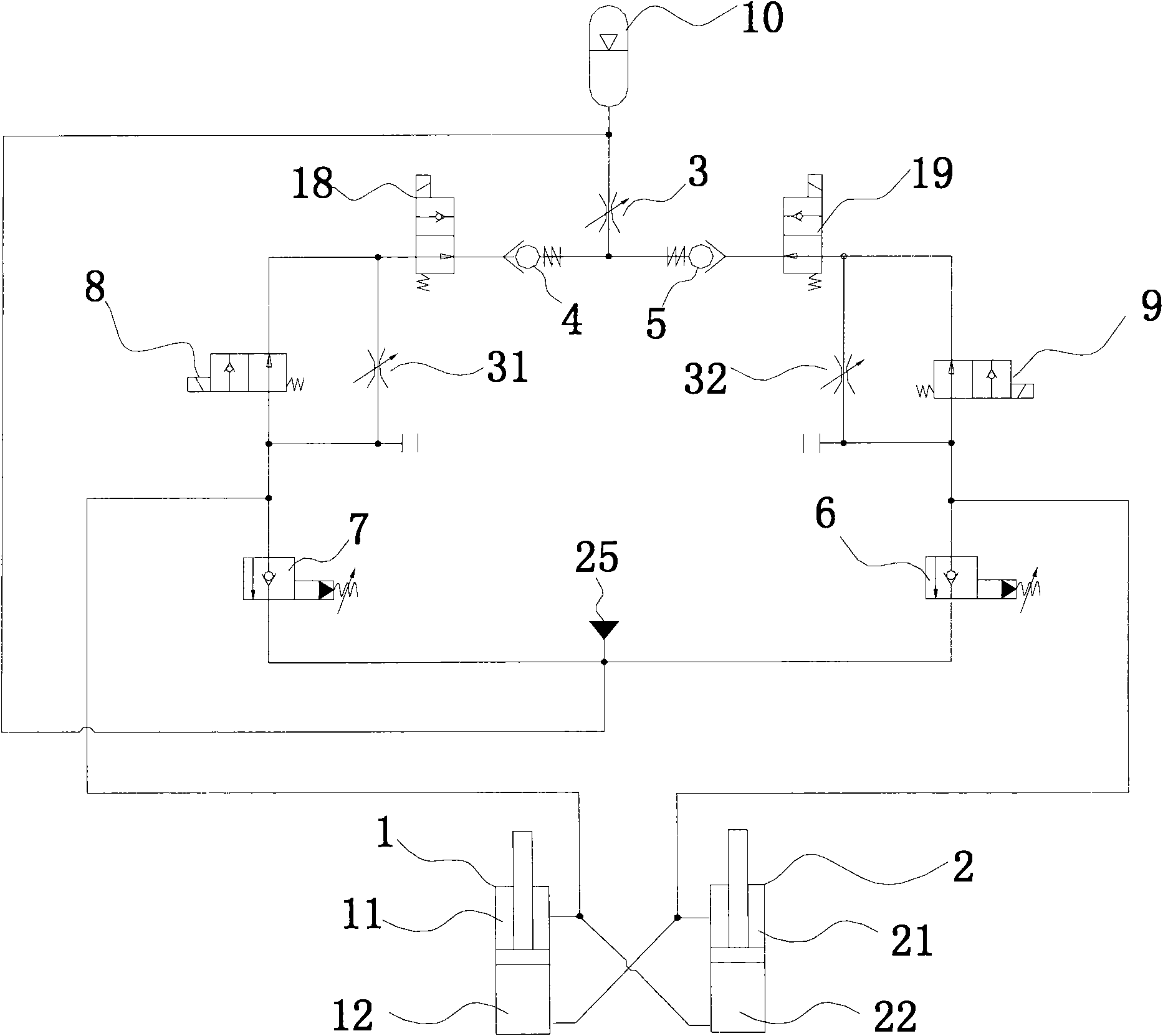

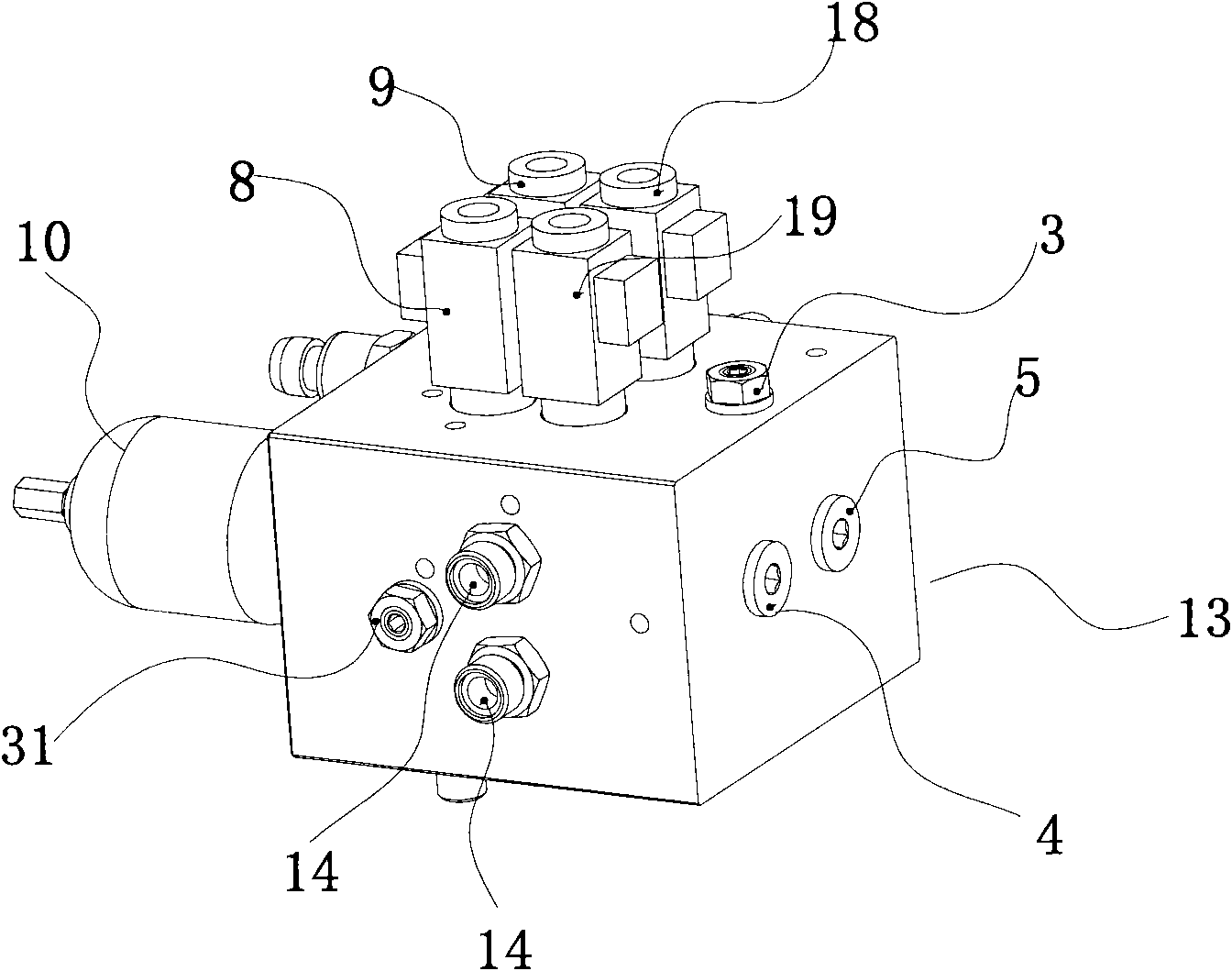

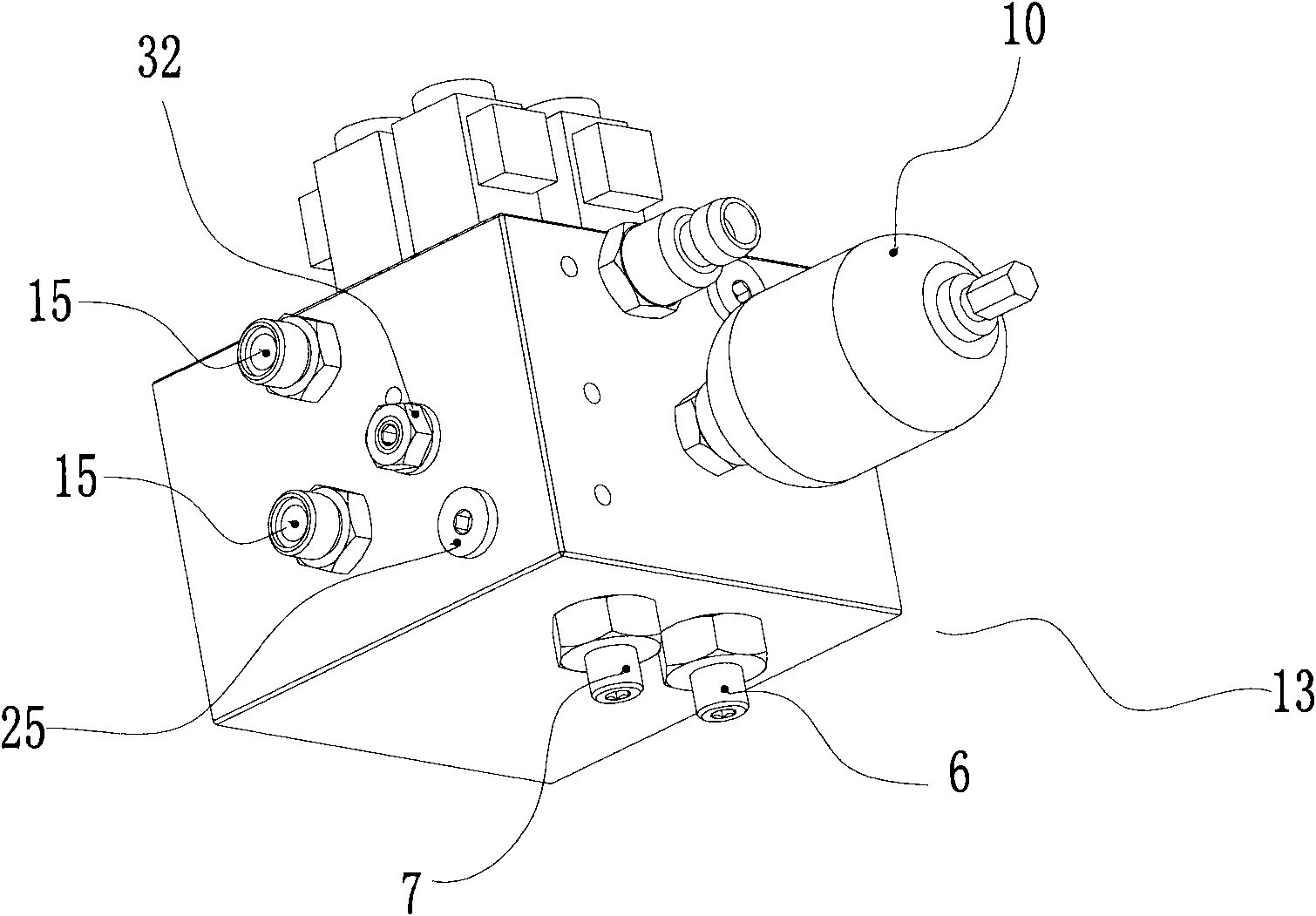

[0019] Such as Figure 1-Figure 3 As shown, the present invention relates to a variable damping control buffer system, including a first hydraulic cylinder 1 and a second hydraulic cylinder 2, the first hydraulic cylinder 1 is divided into a rod chamber 11 and a rodless chamber 12 by a piston, so The second hydraulic cylinder 2 is divided into a rod chamber 21 and a rodless chamber 22 by the piston. The variable damping control buffer system also includes a basic pressure regulating valve 3, a first pressure regulating valve 31, a second pressure regulating valve 32, The first one-way valve 4, the second one-way valve 5, the first one-way overflow valve 6 and the second one-way overflow valve 7, the second hydraulic cylinder rodless cavity 22, the first hydraulic cylinder rod cavity 11. The first pressure regulating valve 31, the first one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com