Oil-water interface measuring device

A measuring device and oil-water interface technology, which is applied in the direction of measuring device, lubrication indicating device, liquid/fluid solid measurement, etc., can solve the problems of unable to guarantee the normal operation of production and low measurement accuracy of the oil-water interface, so as to achieve easy installation and no electromagnetic interference Interference, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

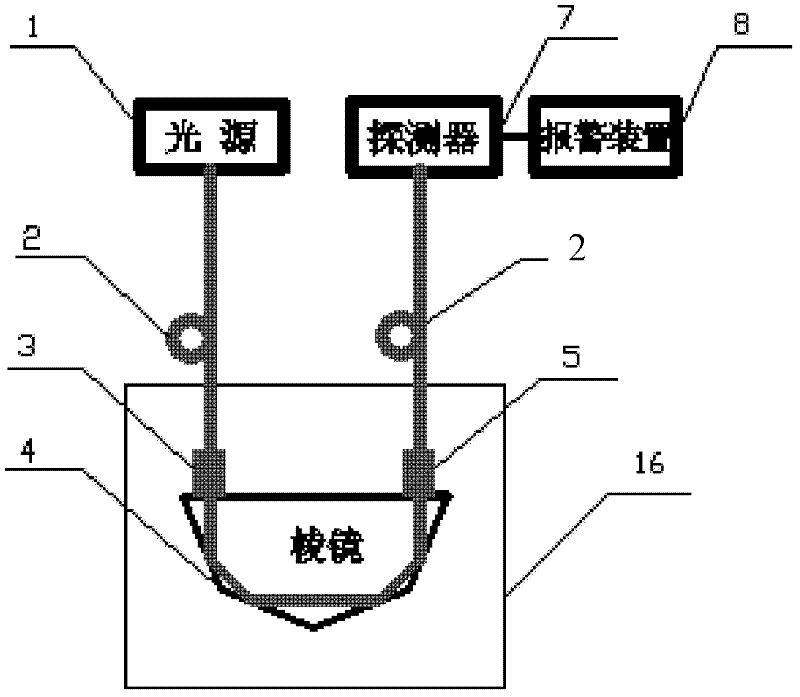

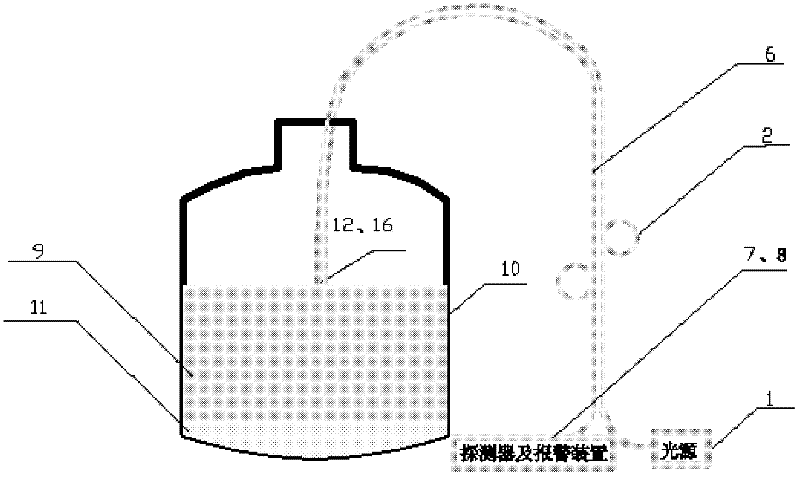

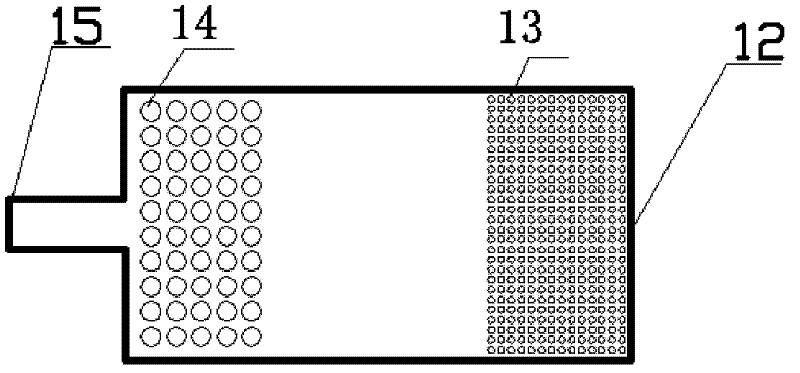

[0036] As shown in Figure 1, the optical fiber type oil-water interface measurement device uses the principle of Fresnel reflection due to the difference in the refractive index of the surrounding medium of the optical sensing probe 16; the light emitted by the light source 1 is transmitted to the first collimator 3 through the optical fiber 2 Realize the collimation of light, and the collimated light is vertically incident into a pentaprism structure 4, and the light undergoes four Fresnel reflections in the pentaprism structure 4, then exits from the second collimator 5, and is transmitted through the optical fiber 2 Finally, enter the photoelectric detector 7, drive the alarm 8 and the signal lamp to alarm through the photoelectric conversion circuit, so as to realize the detection of the liquid level. When the optical sensing probe is placed in the air, the Fresnel reflection condition is met, there is light output from the second collimator 5, and the system is in a standb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com