Torsion sensor

A technology of torsion sensor and center shaft, applied in the field of torsion sensing system, can solve problems such as large deviation of forward and reverse torque or torque measurement range, difficulty in manufacturing forward and reverse two-way torque or torque sensor, inconsistent sensing signal, etc. , to achieve the effect of convenient assembly and installation, good rigidity of the mechanism and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

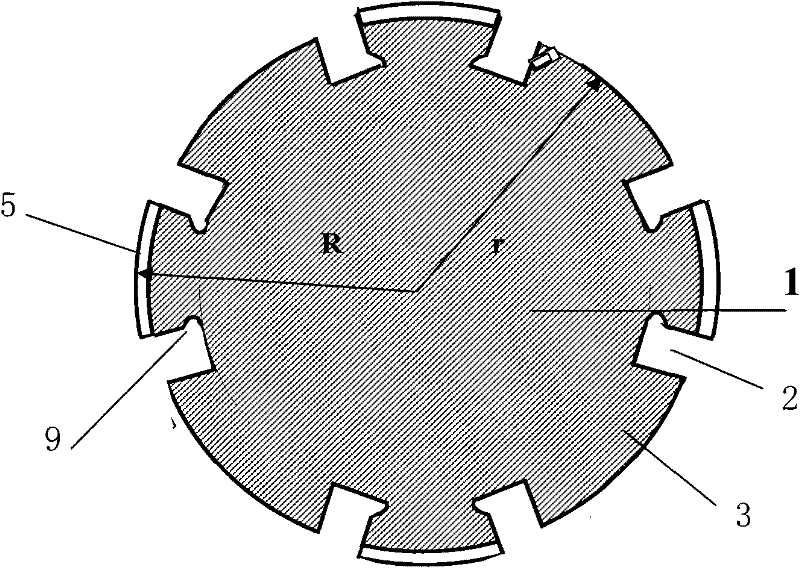

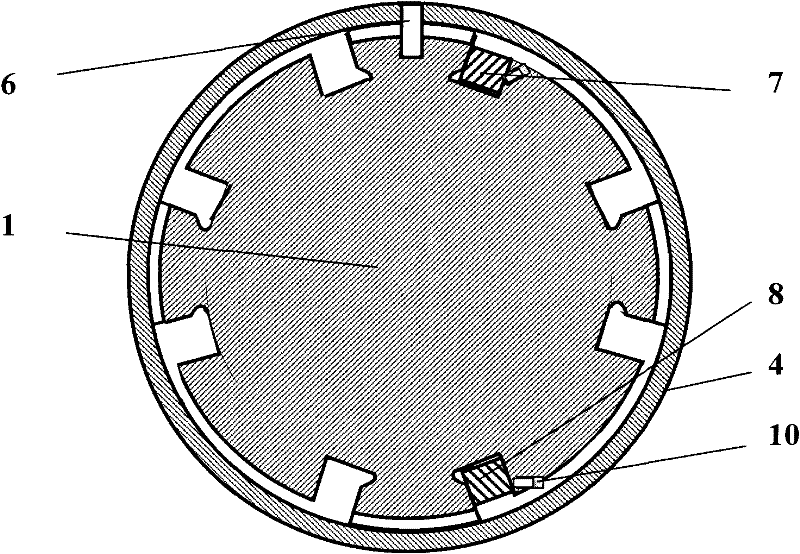

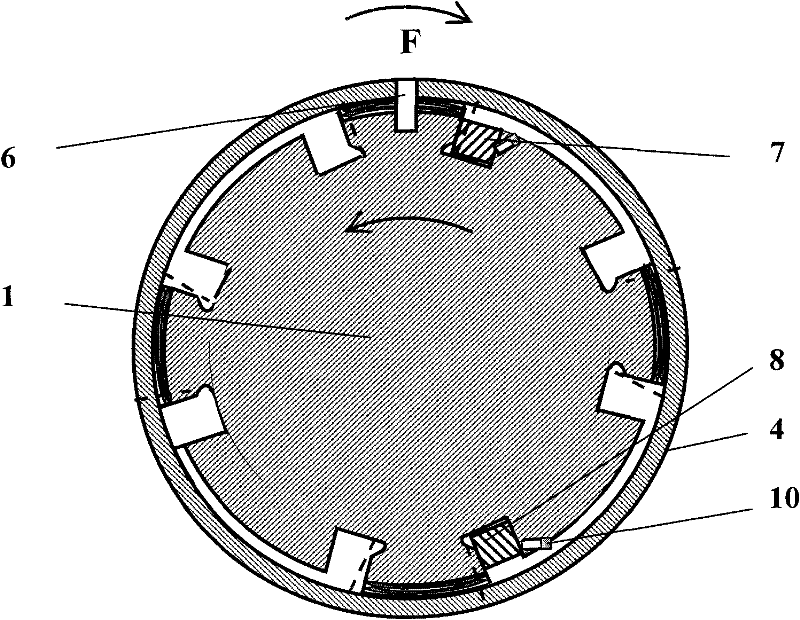

[0026] The torque sensor of the present invention includes a central shaft 1 and a sleeve 4. Grooves 2 are arranged at intervals along the axial direction of the central shaft on the circumference of the central shaft 1. Protrusions 3 are formed between adjacent grooves 2. On the protrusions 3 The connecting racks 5 are arranged alternately, the central shaft 1 is socketed with the sleeve 4 through the connecting rack 5; the fastener 6 is arranged on the sleeve 4, and the sleeve 4 and the central shaft 1 are fixed through the fastener 6; A positive compressive strain material body 7 and a reverse compressive strain material body 8 are arranged at intervals in the groove 2, and both sides of all the compressive strain material bodies are respectively in contact with the groove wall of the groove 2, and one side of the compressive strain material body is in contact with the protrusion 3 fixed connection.

[0027] The bottom end of the projection connecting the rack is provided w...

Embodiment 2

[0032] Such as Figure 4As shown, the forward compressive strain material body 7 and the reverse compressive strain material body 8 are arranged in four grooves 2 with different opening directions of the small chamfer grooves. Others are with embodiment 1.

Embodiment 3

[0034] Such as Figure 5 As shown, the forward compressive strain material body 7 and the reverse compressive strain material body 8 are arranged in six grooves 2 with different opening directions of the small chamfer grooves. Others are with embodiment 1.

[0035] There can be one or more compressive strain material bodies, and the compressive strain material bodies can be placed individually or symmetrically. The collected piezoelectric signal can be in the form of a single compressive strain sensing material body signal or a plurality of compressive strain sensing material body signals connected in series or in parallel, so as to enhance the torsion sensing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com