Experiment table for mass calibration of oil pressure sensor

An oil pressure and sensor technology, applied in the field of sensors, can solve the problems of complex means, lag, harsh use environment, and inability to evaluate calibration quality, and achieve the effects of simple and convenient control, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

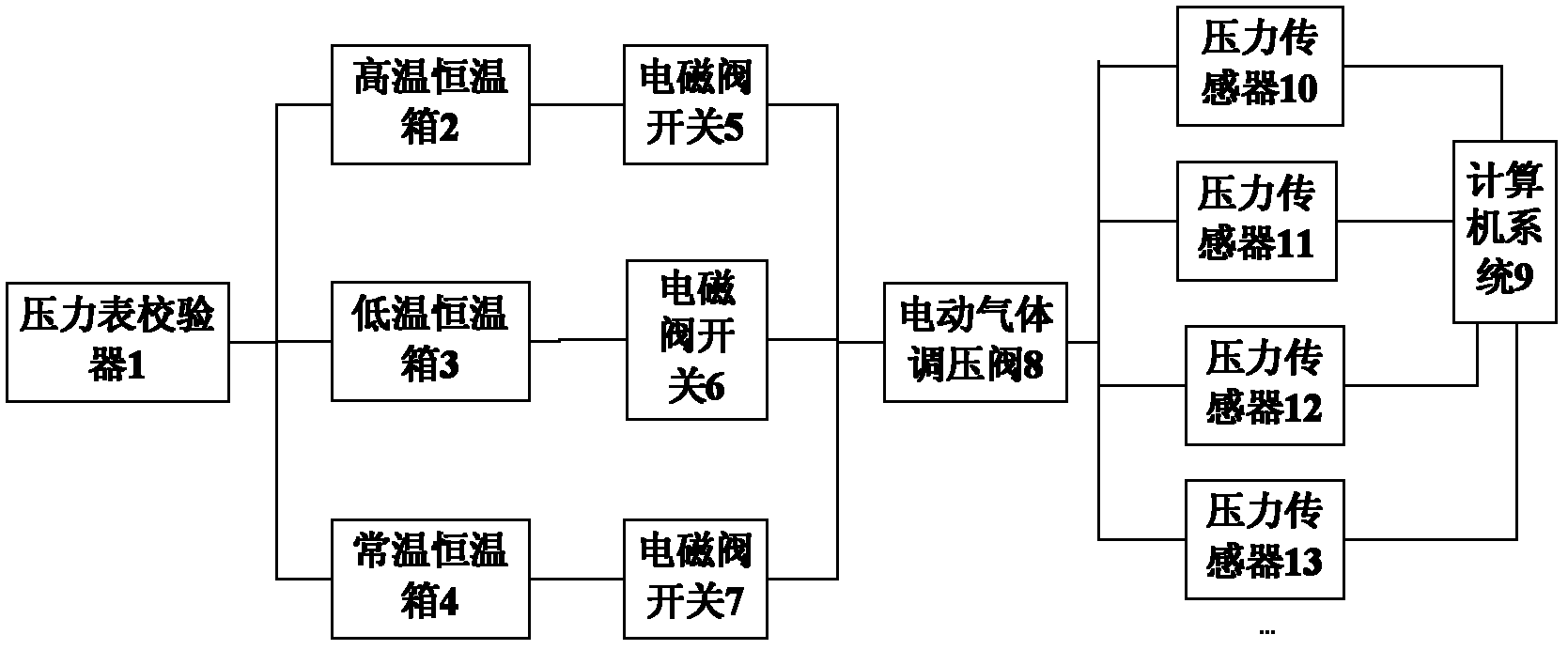

[0018] The present invention uses the pressure gauge calibrator as the pressure signal source, simulates various pressures in the automobile engine oil, obtains different temperature conditions by controlling and adjusting the constant temperature box, and controls the electric gas pressure regulating valve to debug according to a certain ratio to obtain different temperature conditions of the constant temperature box. The pressure of different values is input to each pressure sensor to be calibrated respectively, and the pressure and corresponding temperature output by the sensor are obtained, that is, the calibration process of the entire sensor is completed.

[0019] The present invention will be further described below in conjunction with the examples, but not limited to the content described below.

[0020] The machine oil pressure sensor batch calibration test bench provided by the present invention has a structure such as figure 1 As shown, it is provided with: a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com