Filter element and double-pleated air filter using same

A filter and element technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of not considering the shape of pleats, not considering the gap design, insufficient low pressure loss of filter elements, etc. achieve the effect of reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Next, examples of the double-pleated air filter of the present invention will be described together with conventional examples and comparative examples.

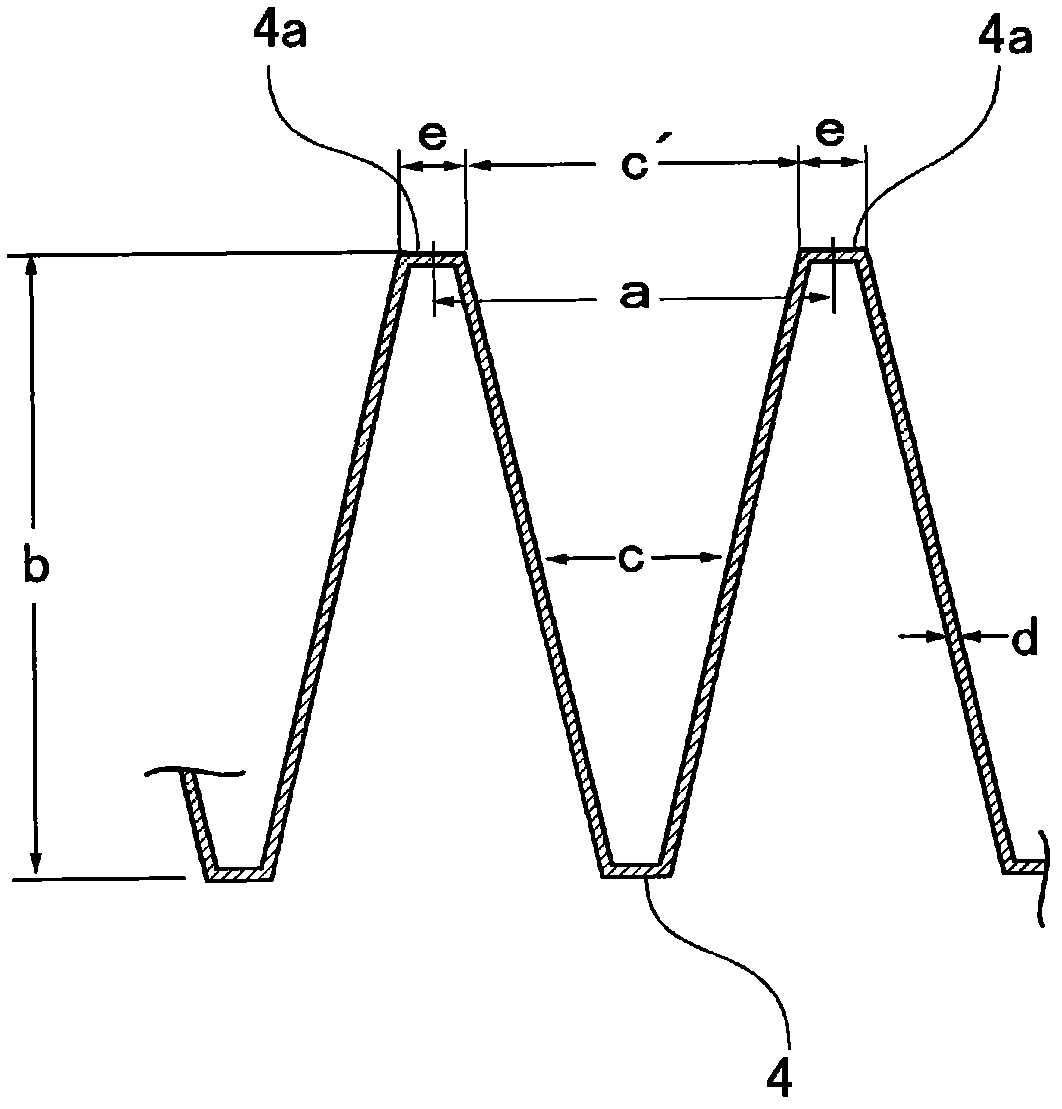

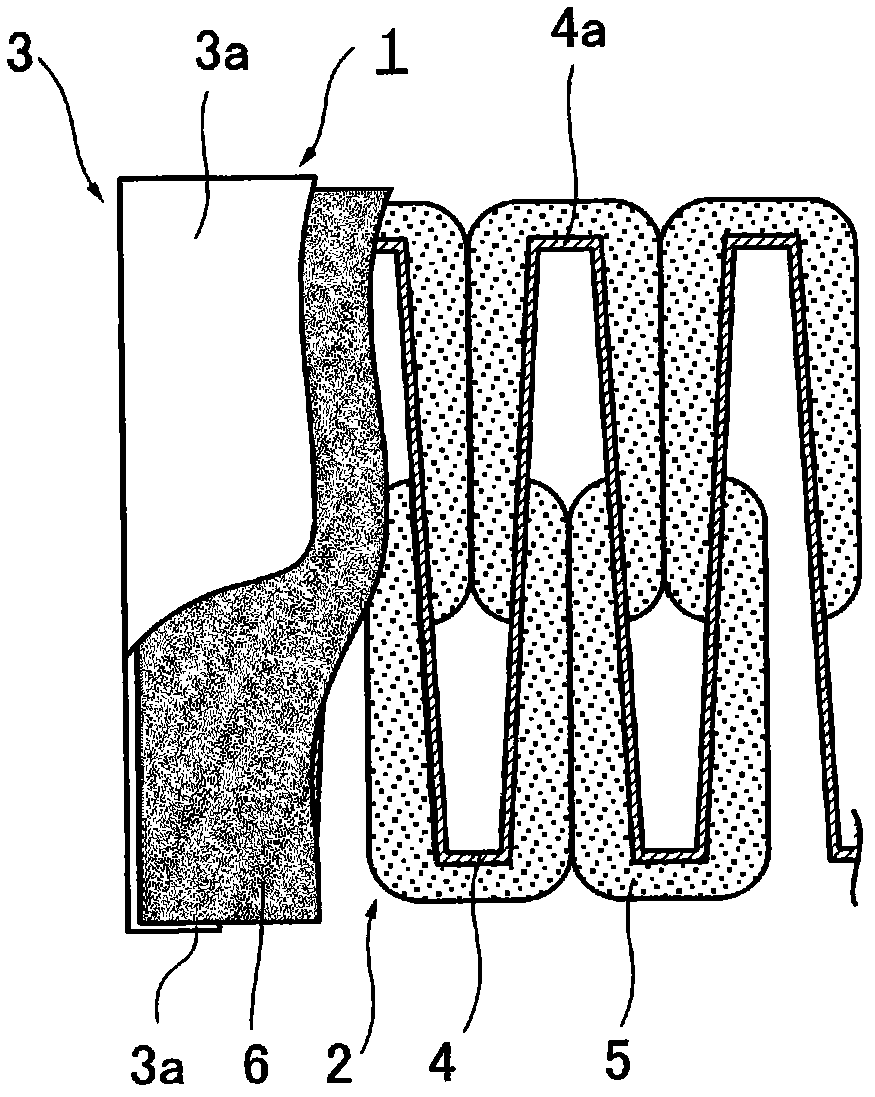

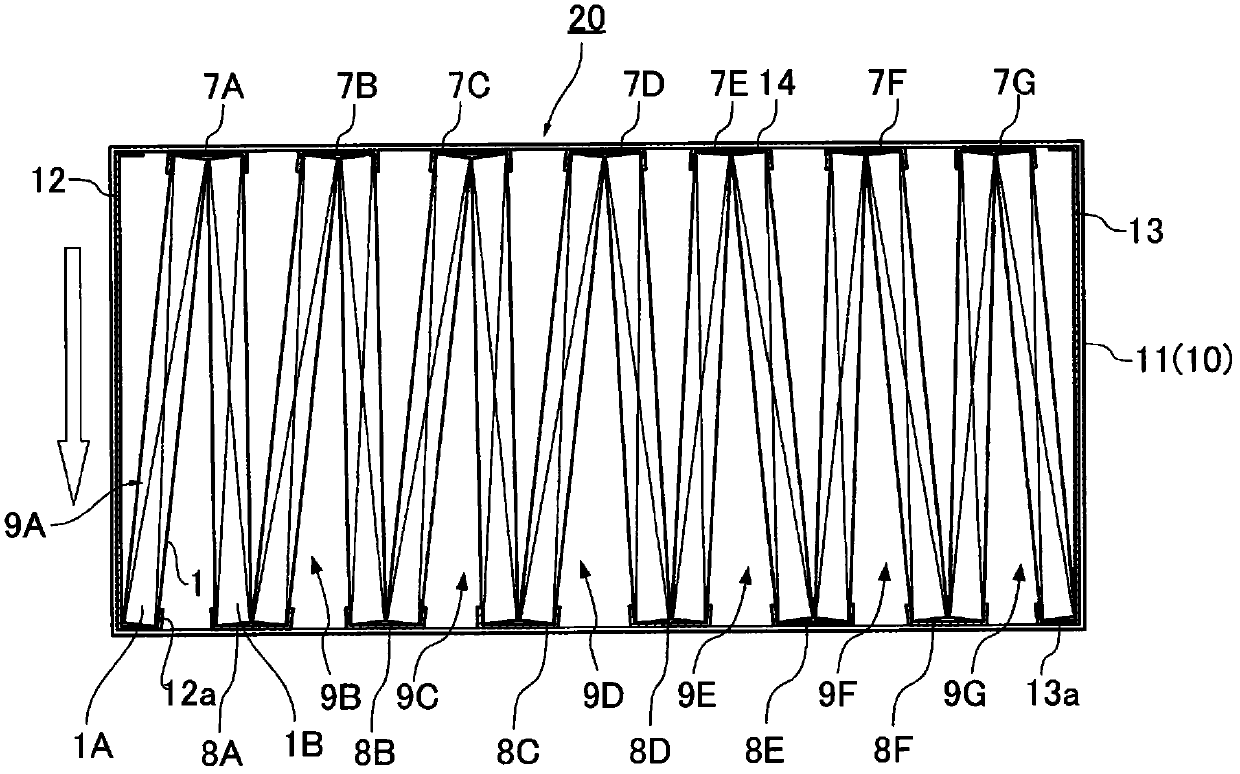

[0058] As Examples 1 to 7 and Comparative Examples 1 to 4, under the conditions shown in Table 1 below, glass with a pressure loss of 265 Pa (at 5.3 cm / s) and an efficiency of 99.97% or more (at 0.2 μm to 0.5 μm) was used. Fibrous filter material, making a filter element 1 whose external dimensions are 280 mm in length x 600 mm in width x 15 mm to 40 mm in folded width, and surrounded by filter frames 11 to 14 made of steel plates with the aid of polyurethane resin sealant , to produce a double-pleated air filter with dimensions of 610 mm in length x 610 mm in width x 290 mm in depth.

[0059] In addition, as Conventional Example 1, except that a filter material made of glass fiber with a thickness d of 0.40 mm, a pressure loss of 265 Pa (at 5.3 cm / s), and an efficiency of 99.97% or more was used, the same procedure w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pressure loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com