Numerical milling processing threaded cutter, and processing method thereof

A technology of thread cutting tools and processing methods, applied in thread cutting tools, manufacturing tools, metal processing equipment and other directions, can solve the problems of multi-tooth thread milling cutter occupying a lot of processing rooms, reducing the efficiency of tool thread processing, and reducing tool service life, etc. Achieve the effect of saving production preparation time, saving thread milling cutter costs, and saving tool costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

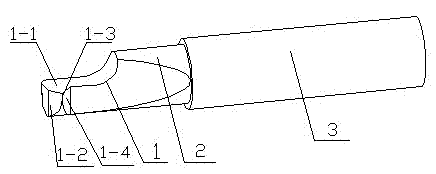

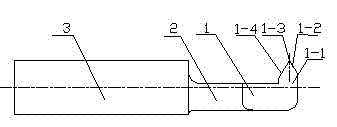

[0042] Such as Figure 2 ~ Figure 4 As shown, a thread cutter for digital milling includes a milling cutter head 1, a milling cutter shaft 2 and a milling cutter handle 3 made of an integral structure. The milling cutter handle 3 is a cylindrical structure with a diameter range of Φ4 to Φ20mm. The tool handle 3 and the milling cutter head 1 are respectively arranged on the two ends of the milling cutter shank 2 , the milling cutter shank 2 is a cylindrical structure, and its diameter is smaller than that of the milling cutter shank 3 . The milling cutter head 1 comprises a rake face 1-1, a main back face 1-2, an auxiliary back face 1-4 and a tool nose angle 1-3, and the clip between the main back face 1-2 and the auxiliary back face 1-4 The angle is 29°~90°, and the center line of the included angle between the main back face 1-2 and the auxiliary back face 1-4 is perpendicular to the center line of the milling cutter bar 2. The structure formed by the main rear face 1-2 and ...

Embodiment 2

[0044] Such as Figure 5 As shown, the milling cutter shank 2 is a cone structure, its maximum diameter is smaller than the diameter of the milling cutter shank 3, and the front face 1-1 of the cutter is a horizontal or arc-shaped surface. The rest of the structure is the same as that in Embodiment 1.

[0045] In the present invention, the included angle between the main back face 1-2 and the auxiliary back face 1-4 may preferably be 30°, 45° or 60°.

[0046] A processing method for digital milling and processing thread cutters, comprising the following steps:

[0047] 1) By accurately calculating the theoretical thread height H=0.866t and the chip clearance of 0.2㎜, the tool nose angle 1-3 of the digital milling thread tool is located at the highest point of the milling cutter bar 2, and the relationship between the tool nose angle 1-3 and the milling tool bar is calculated. The distance between 2 is L=0.866×t+0.2㎜. For example, for M5×0.5-6H thread, the distance between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com