Supported metallocene catalyst and preparation method thereof

A metallocene catalyst and metallocene compound technology are applied in the field of supported metallocene catalysts and their preparation, which can solve the problems of low catalytic activity, and achieve the effects of high catalytic activity, good mechanical strength and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] According to the preparation method of the supported metallocene catalyst of the present invention, the alkylaluminoxane and the metallocene compound have been described above and will not be repeated here.

[0054]The method according to the present invention comprises successively loading alkylaluminoxane and metallocene compound on the carrier under the protection of inert gas. The alkylaluminoxane and metallocene compound can be supported on the carrier by methods known to those skilled in the art. Preferably, the method for sequentially loading an alkylaluminoxane and a metallocene compound on a carrier comprises: under the protection of an inert gas, contacting the carrier with a first solution, the first solution containing the alkylaluminoxane and toluene; contacting the toluene-depleted support with a second solution containing the metallocene compound and toluene, and detoluene removal. In terms of molar ratio, the amount ratio of carrier: toluene: alkyl alum...

Embodiment approach

[0061] According to a preferred embodiment of the present invention, the preparation method of the supported metallocene catalyst comprises:

[0062] In the first step, the triblock copolymer polyethylene glycol-polyglycerol-polyethylene glycol and ethanol are added to the buffer solution of acetic acid and sodium acetate with a pH value of 1-6, at a temperature of 10-60°C Stir until dissolved;

[0063] In the second step, trimethylpentane is added to the solution obtained in the previous step, and stirred at a temperature of 10-60° C. for 1-20 hours;

[0064] Step 3, add tetramethoxysilane to the solution obtained in the previous step, and stir at a temperature of 10-60°C for 10-72 hours;

[0065] In step 4, the solution obtained in the previous step is placed in a closed reaction vessel, and crystallized at a temperature of 30-150° C. for 10-72 hours;

[0066] Step 5, filtering, washing and drying the crystallized product to obtain the hollow spherical mesoporous material ...

Embodiment 1

[0075] This example is used to illustrate the supported metallocene catalyst and its preparation method according to the present invention.

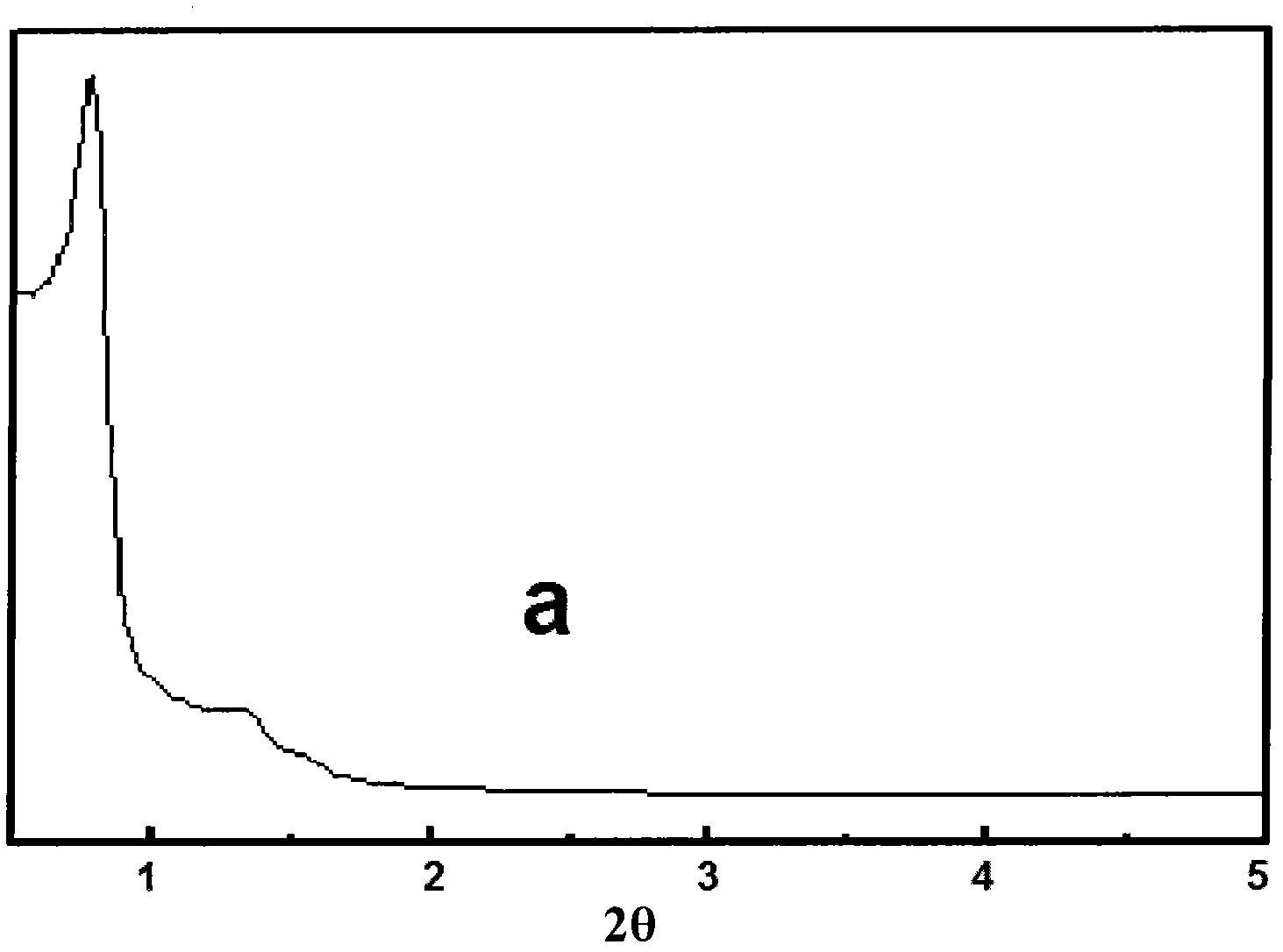

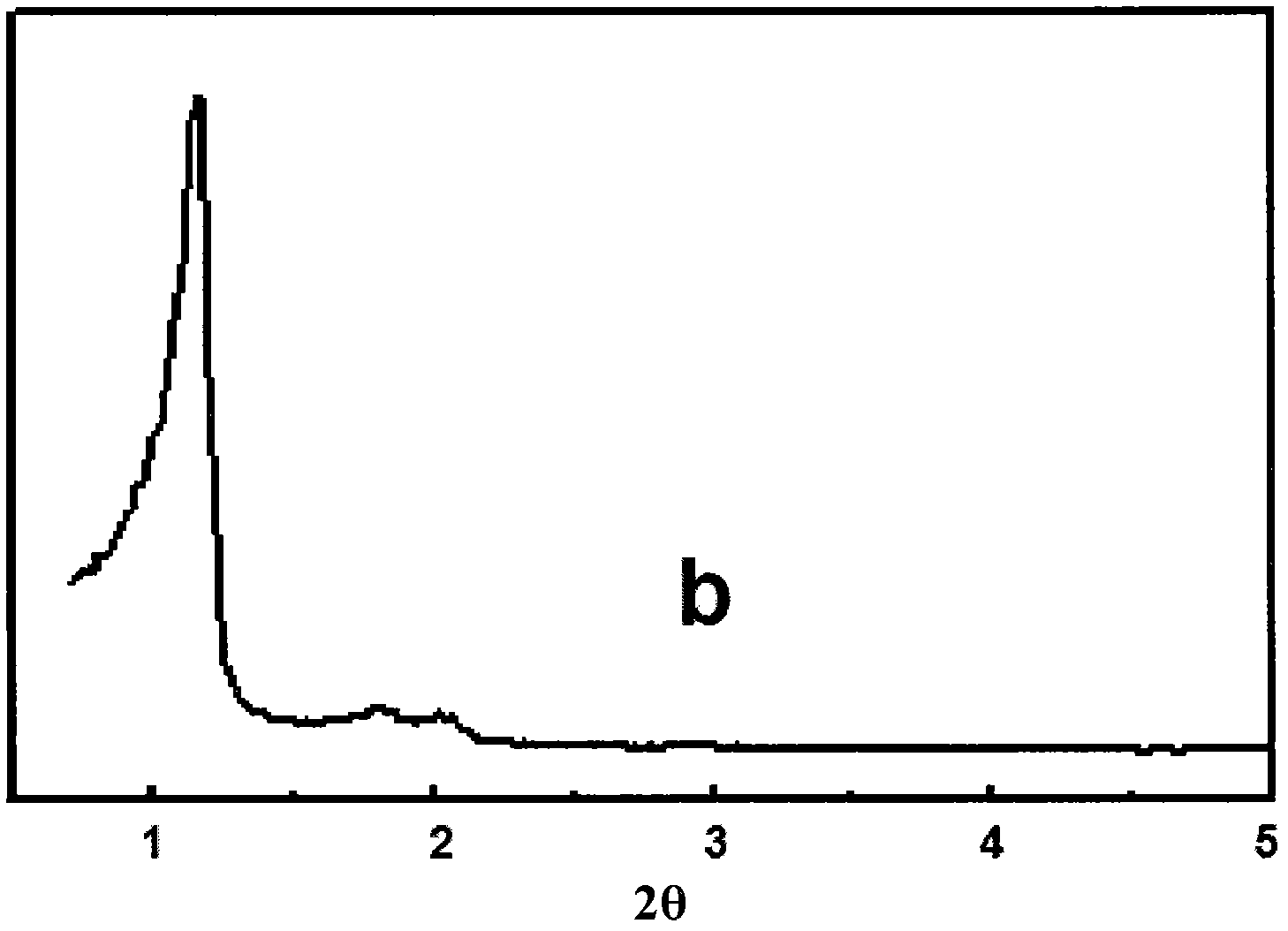

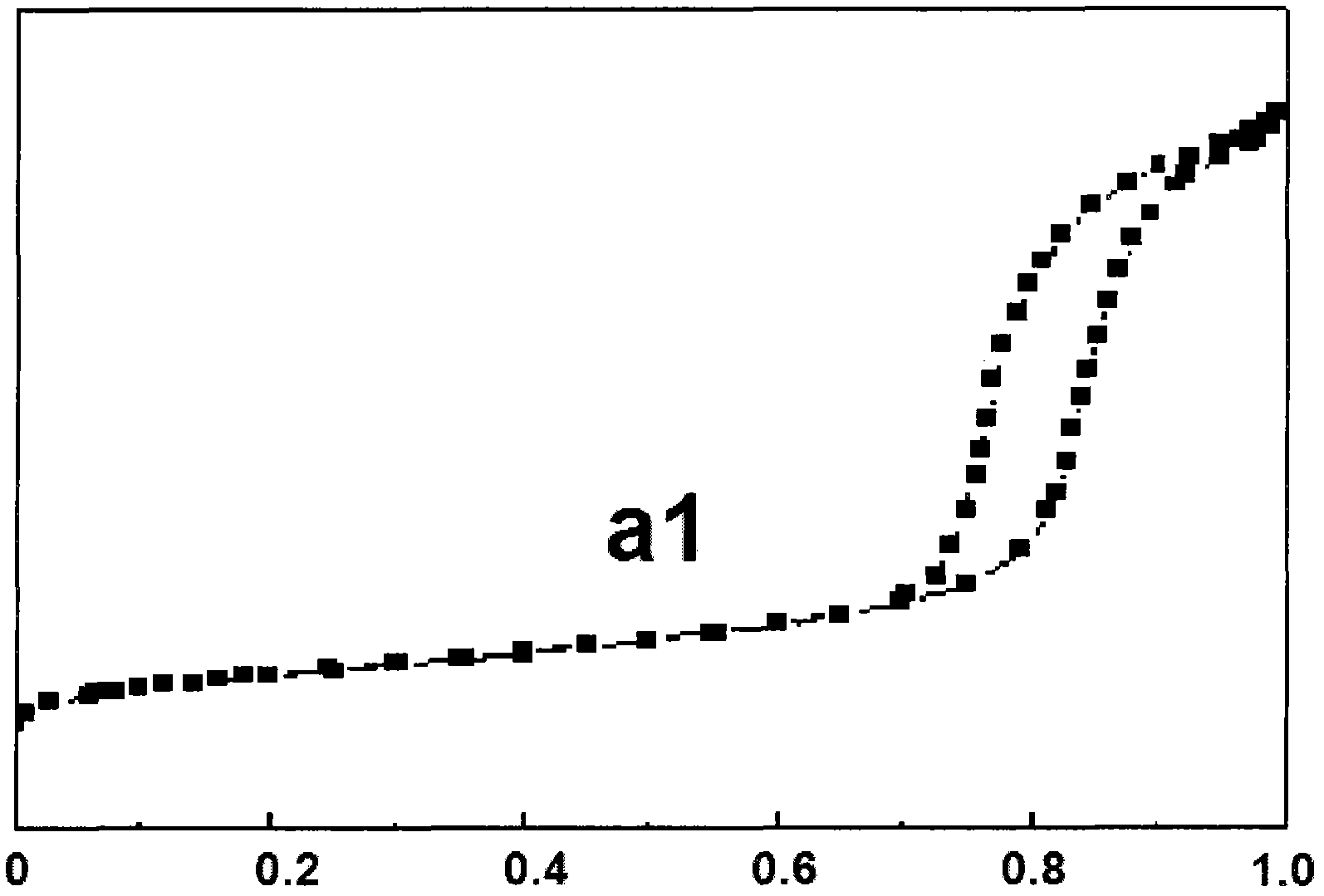

[0076] 1.0 gram of triblock copolymer polyethylene glycol-polyglycerol-polyethylene glycol (purchased from Aldrich, P123) and 1.69 gram of ethanol are added in the buffer solution of acetic acid and sodium acetate of pH=4.4 of 28ml, in Stir at 15°C until polyethylene glycol-polyglycerol-polyethylene glycol is completely dissolved, then add 6g of trimethylpentane to the above solution, stir at 15°C for 8 hours, then add 2.13g of tetramethoxy Add silane to the above solution, stir at 15°C for 20 hours, transfer the solution to a polytetrafluoroethylene-lined reactor, crystallize at 60°C for 24 hours, filter, wash with distilled water, and dry to obtain a hollow Spherical mesoporous silica raw powder.

[0077] The hollow spherical mesoporous silica raw powder was calcined in a muffle furnace at 550°C for 24 hours to obtain hollow spherical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com