Supported metallocene catalyst and its preparation method

A metallocene catalyst and metallocene compound technology, applied in the field of supported metallocene catalyst and its preparation, can solve the problems of small particle size and low catalytic activity of mesoporous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] According to the preparation method of the supported metallocene catalyst of the present invention, the carrier, the alkylaluminoxane, and the metallocene compound have been described above, and will not be repeated here.

[0043] In the above method, silica gel is added before crystallization, and tetraethyl orthosilicate is used as a silicon source, and polyoxyethylene-polyoxypropylene-polyoxyethylene template is added, so that the silica coating produced by hydrolysis of tetraethyl orthosilicate Coated on the surface of silica gel, they together form spherical mesoporous silica.

[0044] The preparation method of the supported metallocene catalyst according to the present invention comprises successively loading alkyl aluminoxane and metallocene compound on the carrier under the protection of inert gas. The alkylaluminoxane and metallocene compound can be supported on the carrier by methods known to those skilled in the art. Preferably, the method for sequentially l...

Embodiment 1

[0063] This example is used to illustrate the supported metallocene catalyst and its preparation method according to the present invention.

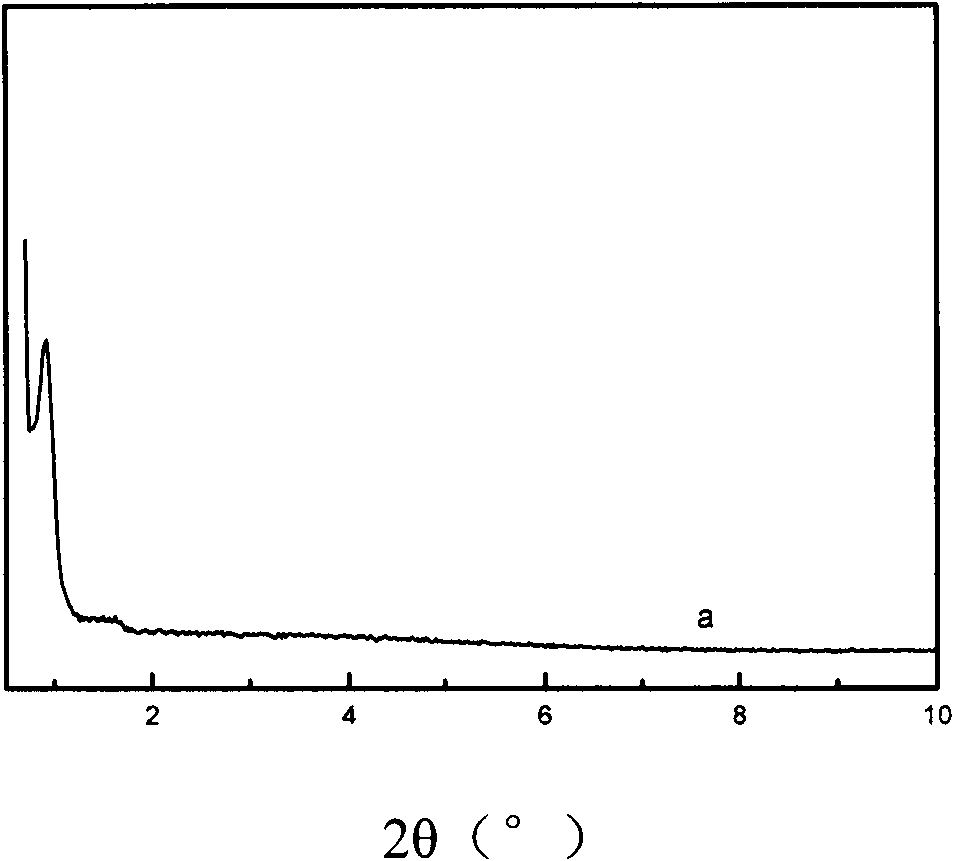

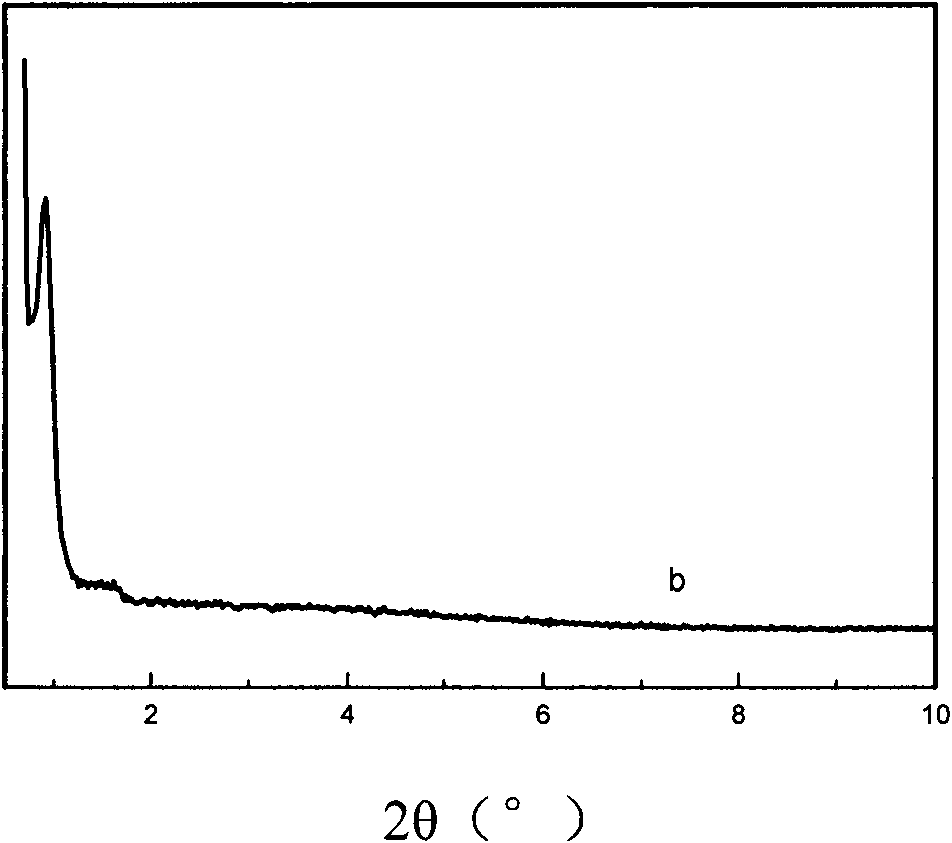

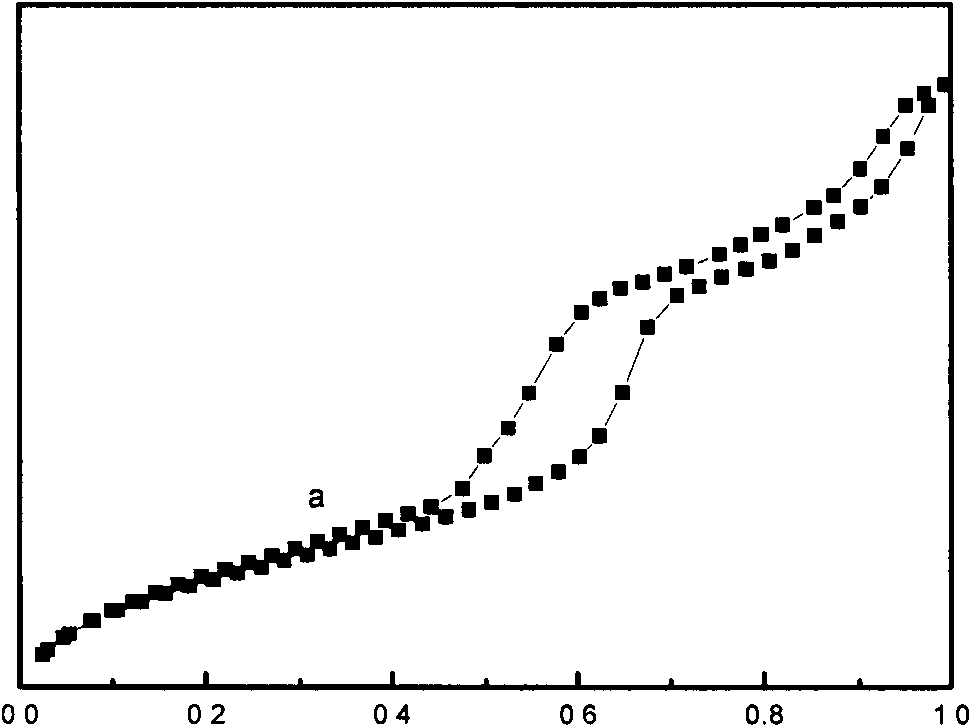

[0064] 2.0 grams of P123 (the substance whose registration number is 9003-11-6 in American Chemical Abstracts, its average molecular weight Mn=5800) and 15 grams of N, N-dimethylformamide (DMF) were added to 11.2 grams of 37% In a solution of hydrochloric acid and 64ml of water, stir at 40°C until P123 is completely dissolved; then add 4.45 grams of ethyl orthosilicate to the above solution and stir at 40°C for 1 hour, then add 1 gram of industrial 955 silica gel, filter, After washing and drying, the original powder spherical mesoporous silica was obtained; the spherical mesoporous silica was calcined in a muffle furnace at 600°C for 24 hours to remove the template agent and obtain the final spherical mesoporous silica (named as GJ-MBQ).

[0065] Spherical mesoporous silica GJ-MBQ was calcined at 400°C for 10 hours under nitrogen prote...

experiment Embodiment 1

[0080] This experimental example is used to illustrate the catalytic activity of the supported metallocene catalyst according to the present invention.

[0081] In a 2-liter stainless steel autoclave, replace three times each with nitrogen and ethylene, then add 200 ml of hexane, raise the temperature of the kettle to 80 ° C, then add 800 ml of hexane, and add 2 ml of hexane with the addition of hexane The concentration is 1 mole / liter triethylaluminum (TEA) hexane solution, then add 55.7 mg MAO / GJ-MBQ-YIN, feed ethylene to raise the pressure to 1.0MPa and maintain it at 1.0MPa, and react at 70°C 1 hour. Obtain 114 grams of polyethylene particle powder, the bulk density (BD) of this polyethylene particle powder is 0.293g / ml, melt index MI 2.16 = 0.048 g / 10 min. It is determined by calculation that the efficiency of the catalyst is 2047gPE / gcat h (ie, 9.3×10 7 g PE / mol Zr h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com