Sintering, mixing and material distributing device for blast furnace

A technology of mixing cloth and blast furnace, applied in the field of blast furnace sintering and mixing cloth device, can solve the problems of poor air permeability, meaningless granulation, and no adjustment means for cloth, so as to avoid empty warehouse or overflow, avoid edge effect and reasonable heat distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

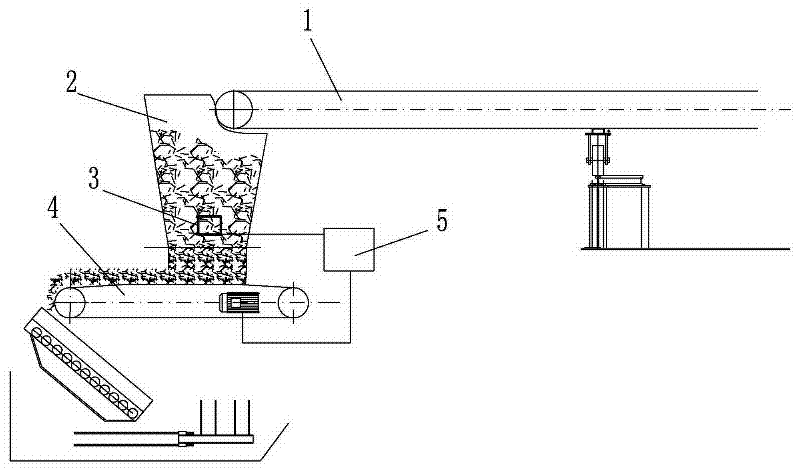

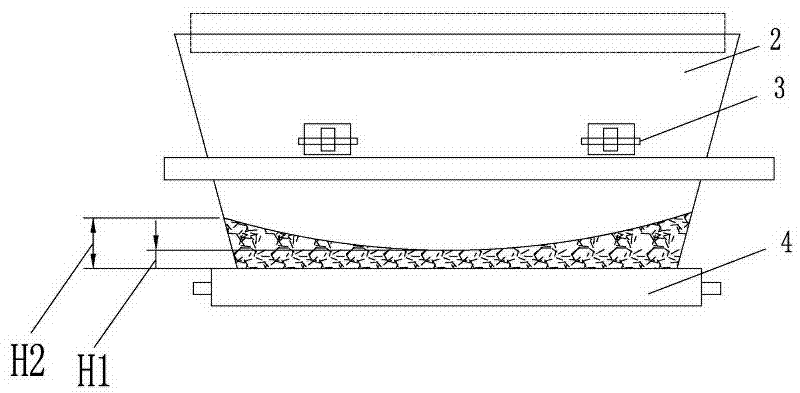

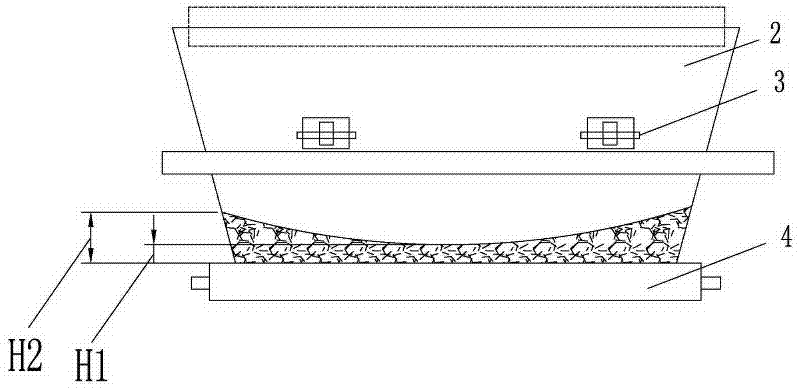

[0015] A blast furnace sintering mixing distribution device, such as figure 1 , figure 2 As shown, it includes the swing head belt 1, the hopper 2 and the wide belt 4. The discharge end of the swing head belt 1 is located above the feed port of the hopper 2, and the bottom surface of the front wall of the discharge port at the lower end of the hopper 2 is a downwardly convex circle. Arc shape, said wide belt 4 is horizontally spaced and arranged below the feed bin 2 .

[0016] A material weighing sensor 3 is installed in the feed bin 2, and the sensor 3 is connected with the speed-regulating motor of the wide belt 4 through a PLC controller 5. The weighing upper limit of the weighing silo is set to 60 tons through the automatic program, and the off-line is 20 tons. When this value is exceeded, the computer will automatically alarm, and the speed of the wide belt 4 can be automatically adjusted in time to avoid the empty bin of the mixed material in the bin or overflow.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com