High-dielectric-constant gate dielectric material and preparation method thereof

A high dielectric constant, gate dielectric technology, applied in metal material coating process, circuits, electrical components, etc., can solve the problem of difficult to form a continuous crystalline structure, and achieve the solution of crystallization, high k value, and large band gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

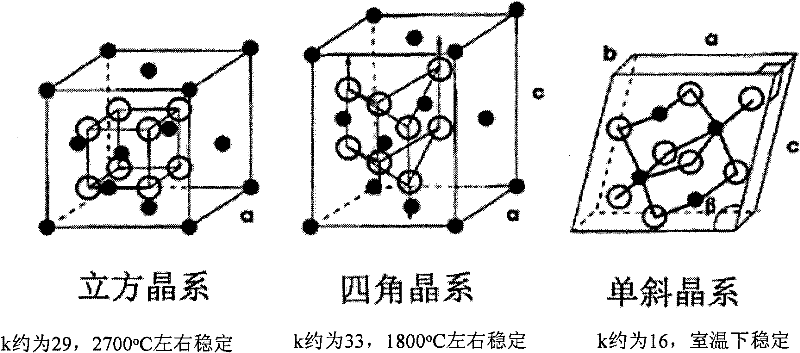

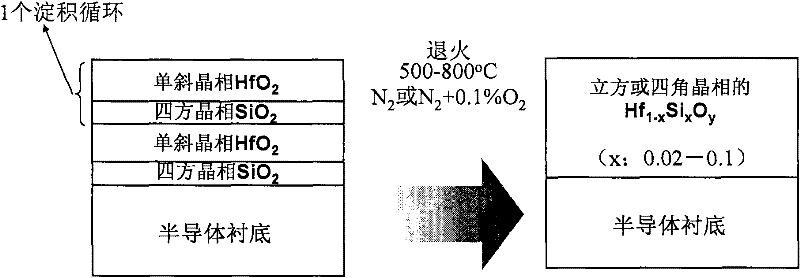

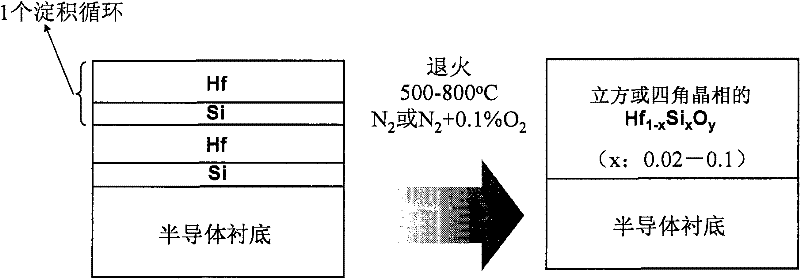

[0025] The following will be combined with Figure 2-4 Describe in detail the gate dielectric material Hf 1-x Si x o y The preparation method comprises the following steps: depositing material A containing Hf source and material B containing Si source or material C containing Hf source and Si source through a film-forming process; then performing thermal annealing, The annealing temperature is 500-800°C to form Hf with cubic or tetragonal crystal phase 1-x Si x o y For thin films, x ranges from 0.02-0.1. Among them, the optimum annealing temperature is 650-800°C; the annealing time is 5-300s, and the optimum is 20-120s; the annealing atmosphere is N 2 or O 2 The volume content is 0.1%-1% N 2 +O 2 The combination.

[0026] It should be pointed out that if Hf 1-x Si x o y If the Si content is not high enough, it is difficult to use the annealing process to make HfSiO with amorphous or monoclinic phase structure z Transform into cubic or tetragonal crystal phase, if...

Embodiment 1

[0028] Embodiment one (PVD film formation):

[0029] First use PVD method to deposit and form a film, the process pressure can be 0.2-1Pa, the sputtering atmosphere can be Ar gas, the flow rate can be 15-50sccm, the temperature range of the semiconductor substrate can be room temperature-400°C, and then at 500-800°C temperature, N 2 Or contain 1% (volume ratio) O 2 N 2 +O 2 Annealed in an annealing atmosphere to form Hf with cubic or tetragonal phase 1-x Si x o y film. Among them, the film forming methods include the following two types:

[0030] Method 1: co-sputtering targets of material A containing Hf source and material B containing Si source, or sputtering targets of material C containing Hf source and Si source, to form an amorphous substrate on the semiconductor substrate phase or monoclinic phase of Hf 1-x Si x o y film. Specifically, materials A and B can be single substance materials such as Hf and Si, or HfO 2 and SiO 2 and other binary oxides, the ma...

Embodiment 2

[0032] Embodiment two (MOCVD or ALD film formation):

[0033] First, use MOCVD or ALD method to deposit and form a film, the temperature of the reaction chamber is 200-600°C, and then at 2 Or contain 1% (volume ratio) O 2 N 2 +O 2 Annealed in an annealing atmosphere to form Hf with cubic or tetragonal phase 1-x Si x o y film. Among them, the film forming methods include the following two types:

[0034] Mode 1: The material A containing Hf source and the material B containing Si source are introduced into the reaction chamber at the same time, so as to form Hf in amorphous phase or monoclinic phase on the semiconductor substrate. 1-x Si x o y film. Specifically, material A includes an organometallic source Hf(N(CH 3 ) 2 ) 4 (TMDEAH), Hf(NC 2 h 5 CH 3 ) 4 (TEMAH), Hf(N(C 2 h 5 ) 2 ) 4 (TDEAH) or inorganic metal source HfCl 4 Any one or a combination of them, material B includes organic source C 8 h 22 N 2 Si(SAM24), HSi[N(CH 3 ) 2 ] 3 (3DMAS) in any ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com