Method for monitoring nuclear reactor canned motor pump operation fault and monitoring system

A technology for operating faults and nuclear reactors, which is applied in the field of nuclear reactor equipment operating fault monitoring methods and monitoring systems, which can solve problems such as large exposure doses to personnel, no vibration spectrum analysis, and rotor displacement that cannot be measured, so as to improve system reliability and maintenance. convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

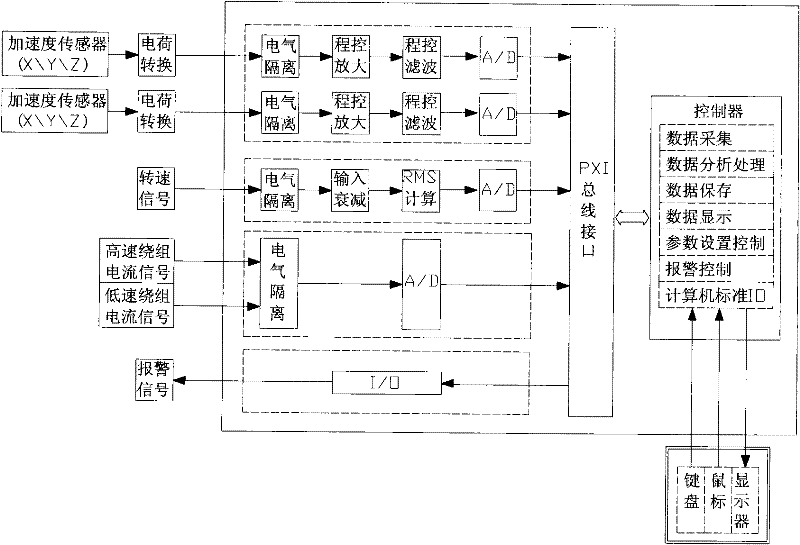

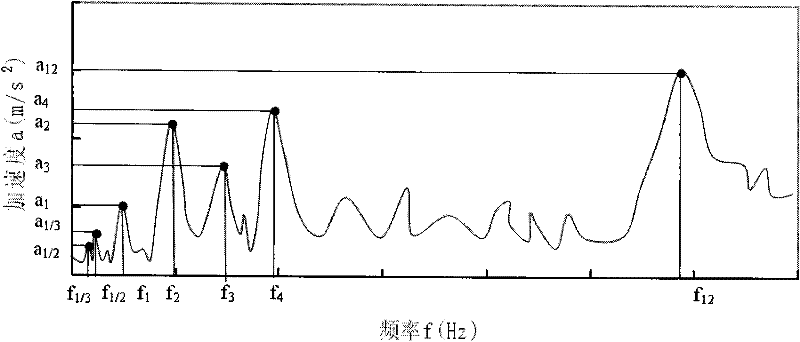

[0050] The monitoring method of the present invention aims at the structural characteristics and working environment conditions of the canned pump, and through signal collection, signal analysis and feature extraction, abnormal identification and alarm, and data reanalysis, a canned pump operation fault monitoring method is established. The specific steps are as follows:

[0051] 1. Signal acquisition

[0052] Signal acquisition includes the acquisition of canned pump vibration acceleration signals, canned pump motor current signals, and canned pump speed signals. The acquisition of canned pump vibration acceleration signals is divided into low-speed sampling and high-speed sampling. The sampling parameters of each signal are shown in Table 1. Among them, the sampling frequency and sampling time can be adjusted, but it is necessary to ensure that the analysis frequency of the low-speed sampling data of the vibration acceleration signal is 1Hz to 1kHz, the frequency resolution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com