Film composition for sliding member

A technology of coating composition and sliding member, which is applied in the direction of lubricating composition, petroleum industry, base material, etc., can solve problems such as low lubricity and abrasion, reduce the reduction of frictional torque, improve wear resistance, The effect of large contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

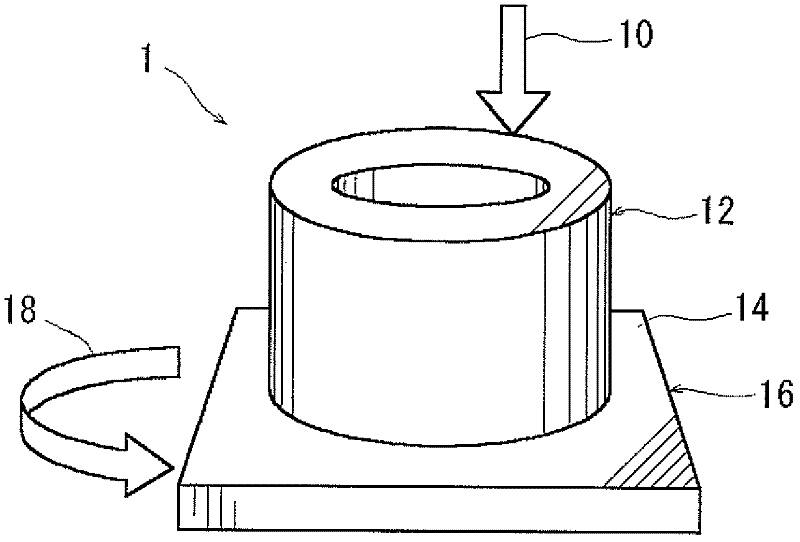

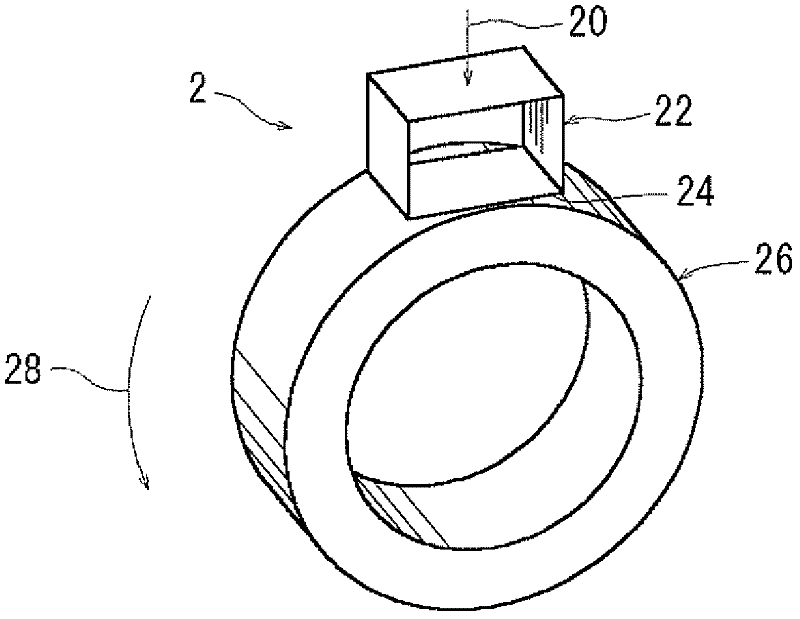

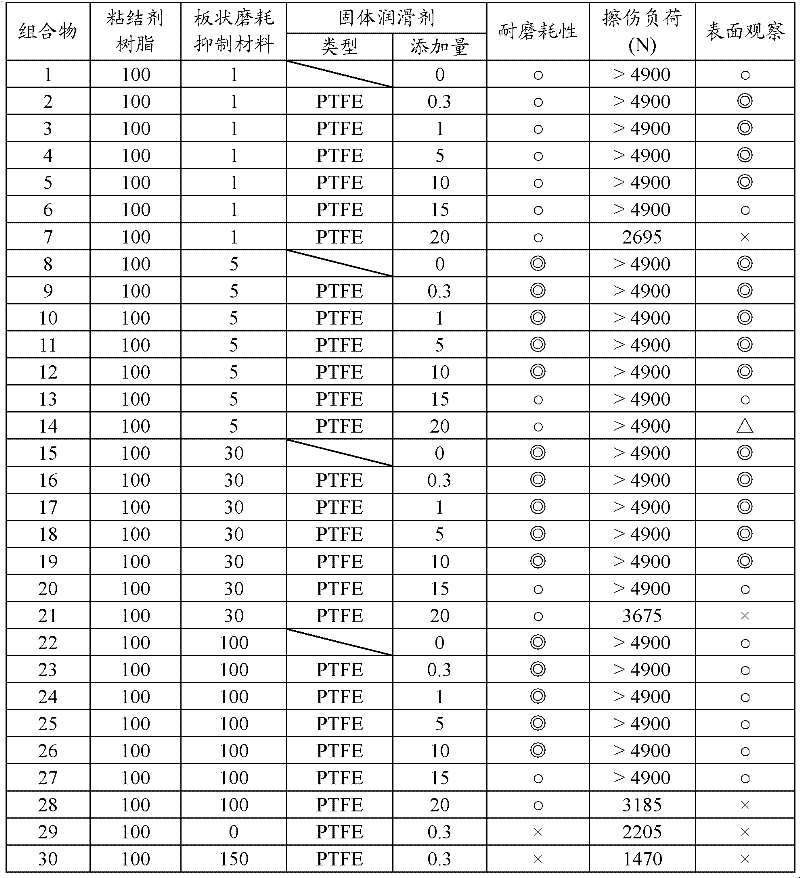

[0015] A detailed description is given below regarding the coating composition for a sliding member according to the present invention. The coating composition for a sliding member according to the present invention is used for the sliding of a coating (coating layer) that forms a dry coating lubricant in order to improve wear resistance, scratch resistance, etc. while reducing the coefficient of friction. Coating composition for components. The basic composition of the coating composition for sliding members includes a binder resin, an inorganic filler as a wear suppressing material, and a solid lubricant as needed. In the following description, the coating composition for a sliding member may be simply referred to as a composition for convenience.

[0016] [Binder Resin] The type of the binder resin is not particularly limited. A known resin used as a binder resin of a coating composition for a sliding member in the related art can be used. As described later, this is bec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com