Residual film recovery device and residual film recovery machine formed by same

A technology of residual film recovery and recycling machine, which is applied in the direction of collectors, agricultural machinery and implements, applications, etc., can solve the problems of difficulty in adapting to residual film recovery operations and complicated mechanisms, and achieve the effect of simple structure and good operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

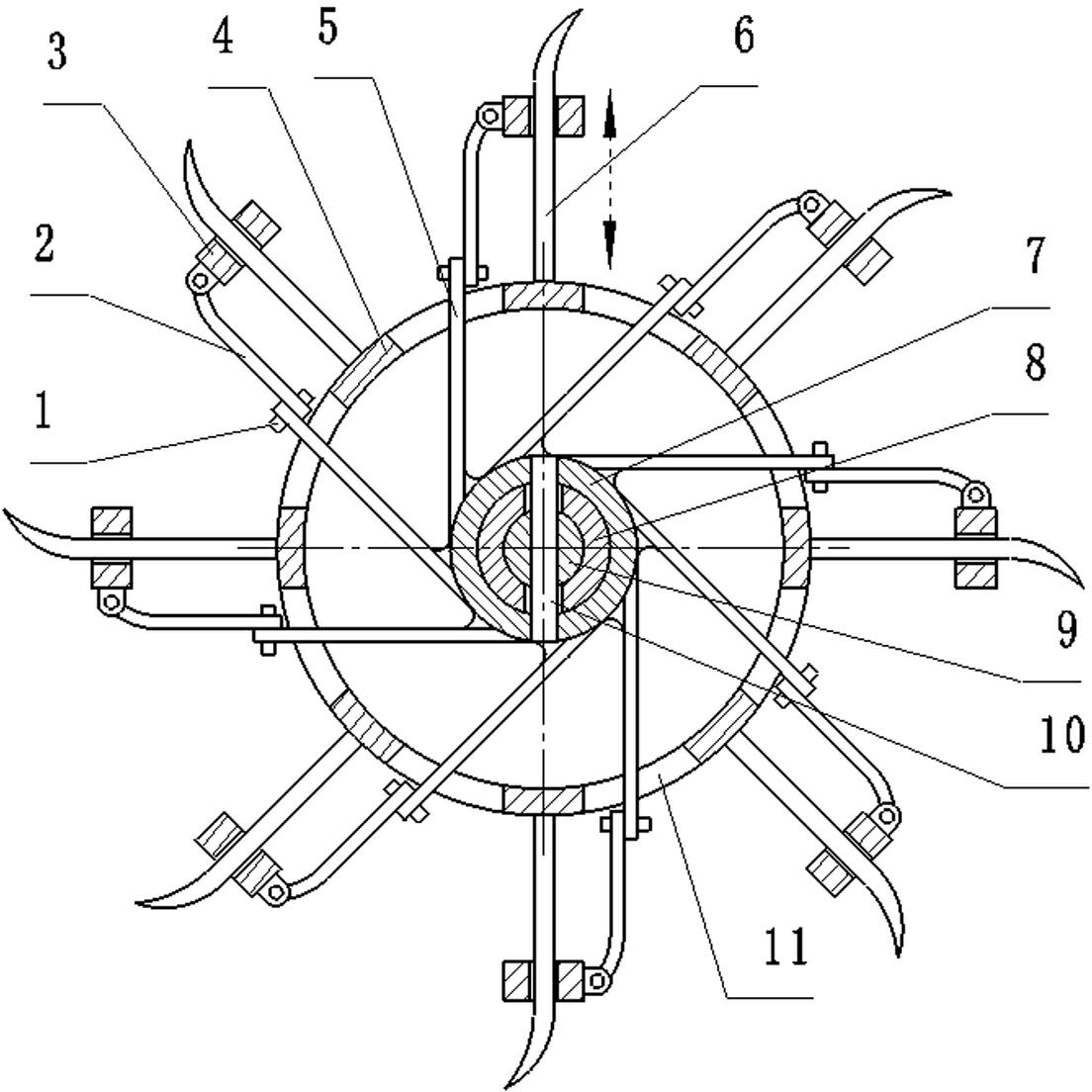

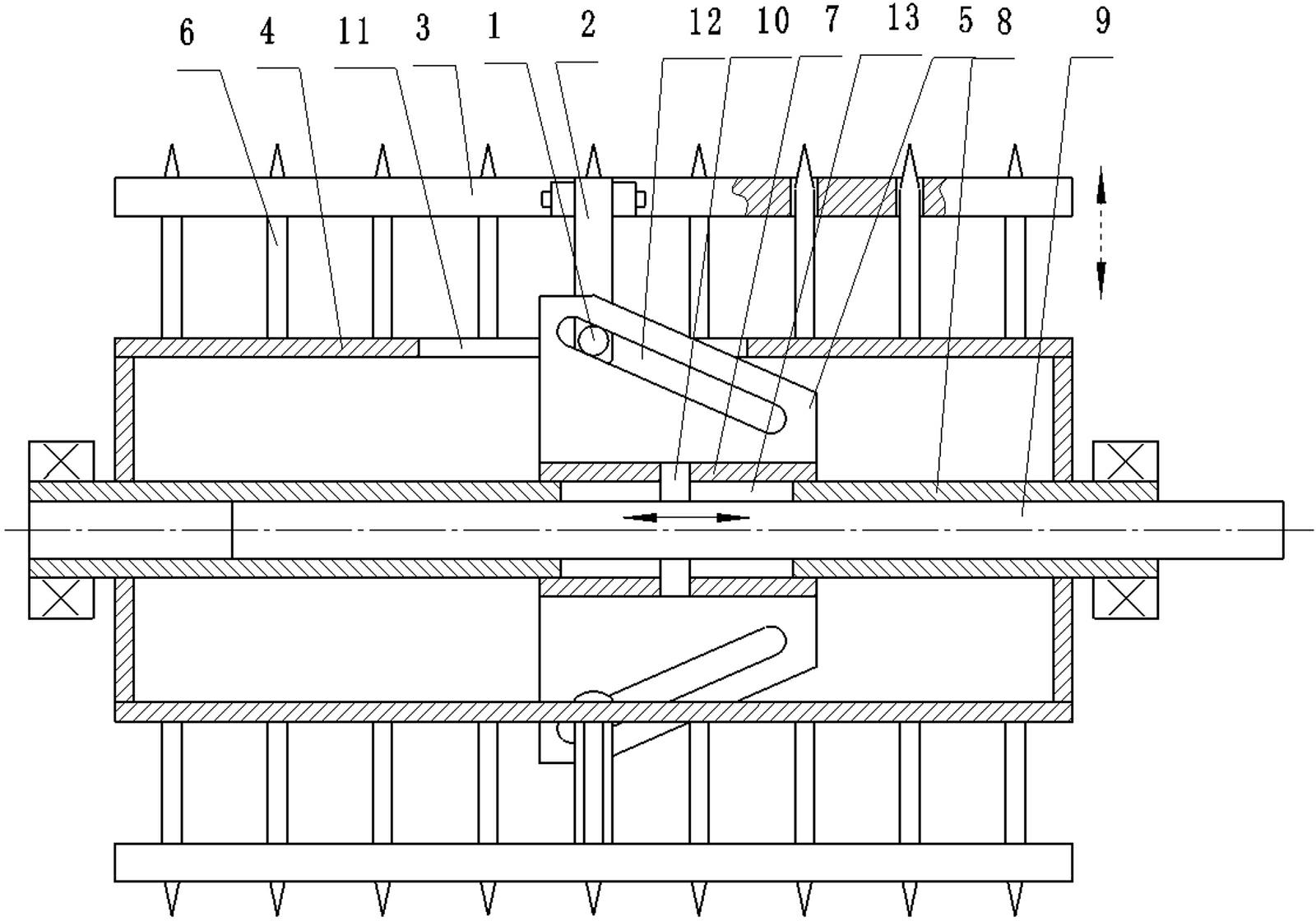

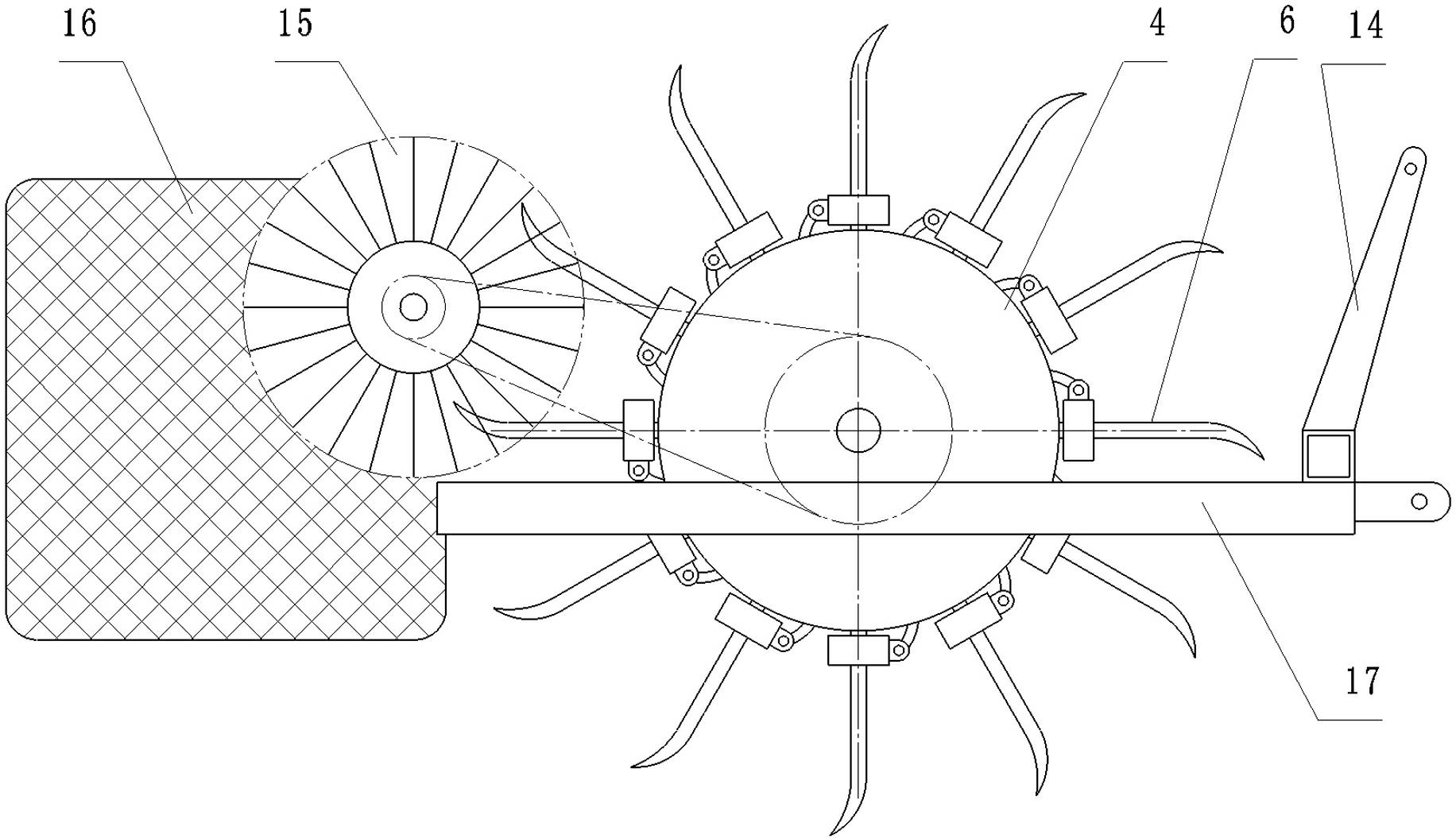

[0023] Embodiment 1: Refer to Figure 1 ~ Figure 3 , is a structural schematic diagram of the residual film recovery device of the present invention applied to a special residual film recovery machine, including a frame 17, a traction suspension frame 14 and a residual film collection box 16, a residual film recovery device is provided on the frame, and a residual film recovery device A film brushing roller 15 is arranged between the residual film collection box 16, and the film brushing roller 15 is a densely clothed elastic bristle cylinder. The residual film recovery device includes a cylindrical hollow cylinder 4, and finger rings are arranged on the outer wall of the cylinder 4. Shaped pick-up teeth 6, the pick-up teeth 6 are axially aligned in a row on the cylinder 4, the pick-up teeth 6 are provided with a film-removing slider 3 that can slide on the tooth body, and the film-removing slider 3 is a strip-shaped plate, Holes matching the cross section of the pick-up teeth...

Embodiment 2

[0024] Embodiment 2: refer to Figure 4 , is an embodiment in which the residual film recovery device of the present invention is applied to a combined land preparation machine. Compared with Example 1, the difference of this embodiment is that the frame 17 at the front of the residual film recovery device is also sequentially provided with round Sheet rake group 18, road wheel 19 and spike-toothed rake 20.

Embodiment 3

[0025] Embodiment 3: refer to Figure 5 , is an embodiment in which the residual film recovery device of the present invention is applied to a combined land preparation machine. Compared with Example 1, the difference of this embodiment is that the frame 17 at the front of the residual film recovery device is also sequentially provided with flat Floor 21, disk harrow group 18 and road wheel 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com